Metal Control Solutions for the Recycling Industry

Recycling operations handle a wide variety of materials, including metal, plastic, paper, glass, electronics, rubber, and more, often mixed and highly contaminated. MPI's separation systems are used to sort, clean, and recover ferrous and non-ferrous metals from these streams to:

-

Reduce landfill waste

-

Comply with environmental and recycling mandates

-

Protect downstream shredders, grinders, and granulators from metal damage

MPI equipment is commonly integrated into MSW (municipal solid waste), MRFs (materials recovery facilities), e-scrap, C&D (construction and demolition), tire recycling, and plastics recycling lines.

MPI helps recyclers:

-

Maximize metal recovery and profit margins.

-

Protect valuable processing equipment.

-

Streamline material sorting for higher throughput.

-

Ensure cleaner, safer, and more sustainable operations

From municipal waste to industrial scrap to precision plastic pellet cleaning, MPI’s magnetic and metal detection solutions bring reliability, efficiency, and purity to every stage of the recycling process.

Turnkey Solutions for Recycling From Magnetic Products, Inc

-

Maximizes Metal Recovery Rates

MPI separators efficiently remove ferrous and non-ferrous metals, increasing the quality and resale value of recyclables.

-

Protects Shredders, Crushers, and Granulators

Tramp iron removal reduces blade and equipment wear, lowering maintenance costs and extending machinery life.

-

Supports Regulatory and Environmental Compliance

Separating metals from waste supports sustainability targets and ensures compliance with EPA, state, and municipal recycling requirements.

-

Reduces Landfill and Contamination Penalties

Cleaner waste streams help processors avoid fines from haulers, end users, and regulatory agencies.

-

Handles High-Volume, Harsh Conditions

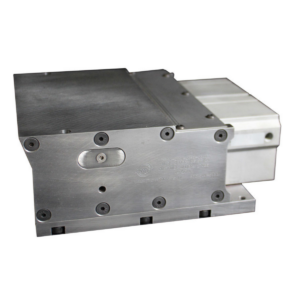

MPI’s rugged designs are built for abrasive, heavy-duty operations. They feature reinforced housings, large magnet arrays, and wear liners.

-

Automates Sorting to Improve Throughput

MPI supports automated lines with minimal human oversight by integrating self-cleaning or continuous magnetic systems.

-

Customizable for Mixed or Specialized Material Streams

Whether you handle e-waste, plastic flakes, scrap metal, or glass, MPI offers tailored configurations to meet your process needs.

-

Increases Sorting Efficiency with Compact Footprints

Compact, modular designs make integrating MPI equipment into existing conveyors or drop points easy without requiring a complete line redesign.

How Does the Recycling Industry Use Magnets and Industrial Conveyors?

US Customary Units

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

| Eddy Current Separators | Downstream from shredders or screens | Repels and ejects non-ferrous metals (aluminum, copper) from bulk flow using magnetic rotor. | Post-air classifier | Final magnetic/non-magnetic split before downstream material bins |

| Magnetic Head Pulleys | At the end of conveyors | Automatically separates ferrous metals from moving waste streams | Post-air classifier | Final magnetic/non-magnetic split before downstream material bins |

| Suspended Crossbelt Magnets | Over conveyors or chutes | Lifts and removes large ferrous items from material belts; available in manual/self-clean | Bulk loading / infeed | Remove large iron/steel from incoming mixed material |

| Drum Separators | Pre-screening or fines recovery | Continuously removes ferrous debris as material flows around magnetic drum | Bulk loading / infeed and pre-screening or trommeling | Remove large iron/steel from incoming mixed material and clean ferrous from sorted size fractions |

| Chute Magnets and Hump Magnets | Gravity-fed drop points | Capture tramp metal in sloped material flow using high-strength magnetic plates | Pre-screening or trommeling and plastic pellet cleaning | Clean ferrous from sorted size fractions, and remove fines from reprocessed flake or ground plastic |

| Drawer Magnets (Heavy-Duty) | Fine plastic pellet or granulate recovery | Remove metal fines from recycled flake or powder pre-packaging or pre-extrusion | cleaning phases | Remove fines from reprocessed flake or ground plastic |

| Metal Detectors | Final quality control after magnet separation | Detect all metal types and trigger reject of contaminated product or bale | Final QA inspection | Detect any residual metal missed by magnets for reject/divert |