MPI’s Intell-I-Mag® is a sensor-enabled magnetic separator monitor that enhances the tracking and management of magnetic separation performance. It provides real-time magnetic load detection and features integrated digital dashboards, offering operators insights into saturation levels and cleaning cycles while ensuring regulatory compliance. The system is accessible via mobile devices, local displays, or remote dashboards, enabling effective oversight of individual separators and entire facilities.

MPI’s magnetic separation solutions for bulk gravity applications are designed to remove ferrous contaminants from free-flowing dry materials such as powders, granules, and pellets. Installed in chutes, hoppers, or silos, these high-performance magnets—such as drawer, plate, and hump separators—deliver maximum capture efficiency using powerful rare-earth magnet technology.

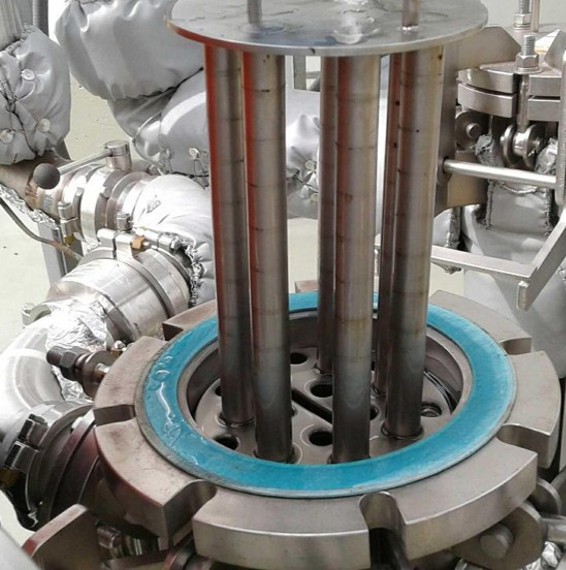

MPI provides high-intensity magnetic separation solutions for liquid applications, specifically designed to eliminate ferrous and weakly magnetic contaminants from viscous liquids, slurries, and emulsions in pressurized lines. Their stainless-steel trap assemblies ensure minimal pressure drop and are easy to clean, making them ideal for food, chemical, and pharmaceutical processes. MPI's liquid traps enhance product purity and improve process efficiency.

MPI's magnetic separation systems are designed to safeguard pneumatic conveying lines from metal contamination in fast, pressurized material flow. Suitable for powders, flakes, or granular materials, these systems utilize rare-earth magnetic cartridges and effective flow designs to trap ferrous contaminants without disrupting system pressure and easily integrate into dilute or dense phase conveying systems.

MPI's magnetic sorting systems, which include Eddy Current Separators, Magnetic Head Pulleys, and Crossbelt Suspended Magnets, provide efficient and continuous separation of ferrous and non-ferrous metals from bulk materials. Designed for recycling, mining, and waste processing, these industrial-grade systems prioritize precision, reliability, and durability to ensure optimal metal recovery.

MPI's electronic inspection systems feature conveyor, pipeline, and combination checkweigher-metal detectors that identify and eliminate all metal contaminants, including ferrous, non-ferrous, and stainless steel. These systems suit packaged, bulk, or pumped product streams, offering high-sensitivity detection, real-time data logging, and seamless integration into quality control programs.