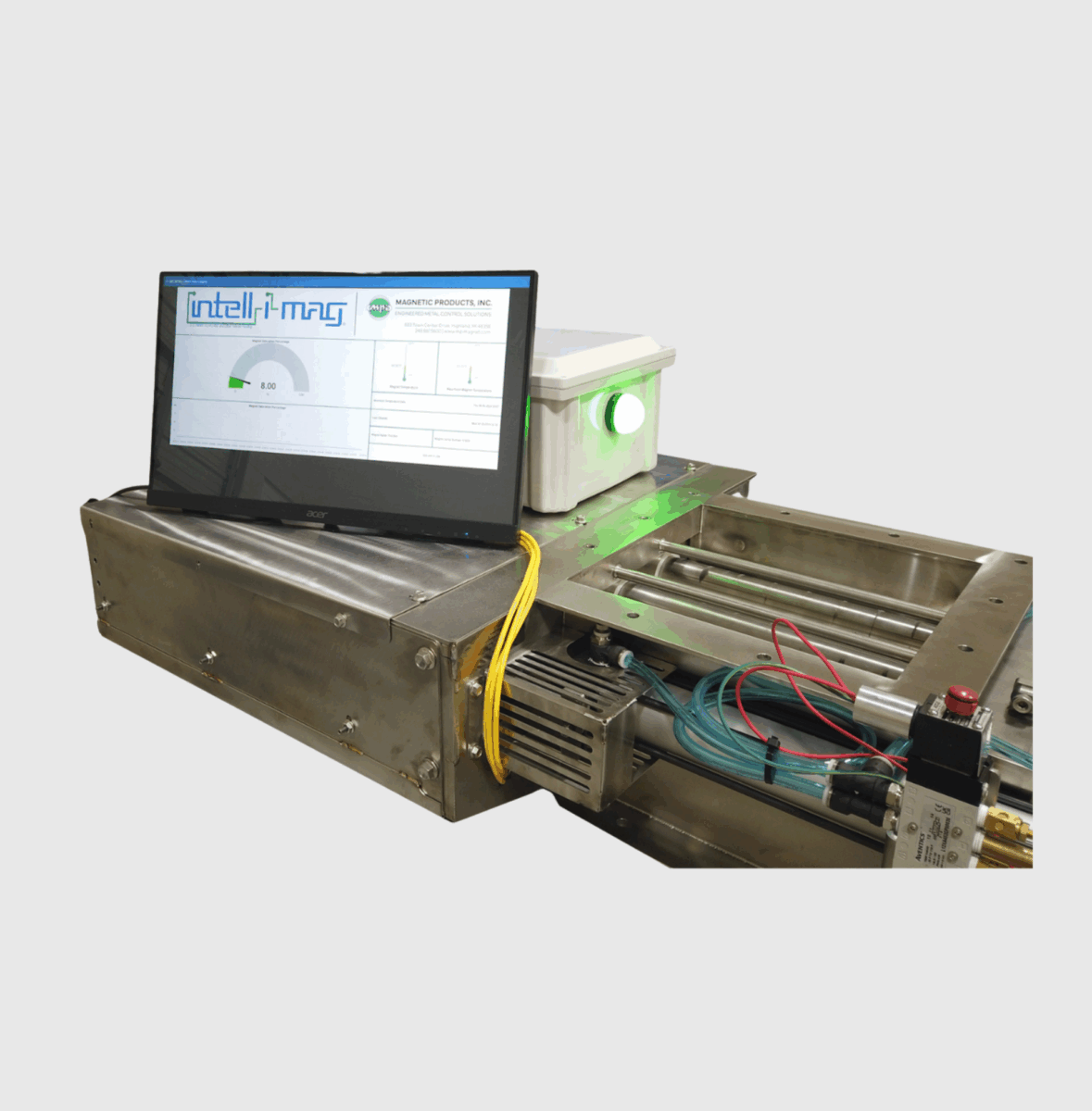

MPI's Intell-i-Mag® App and Controller revolutionize magnetic separator management by enabling real-time monitoring of magnetic performance, cleaning cycles, and equipment conditions through Bluetooth® or network integration. Compatible with most MPI separators, it features user-friendly dashboards, maintenance alerts, and downloadable compliance logs to simplify adherence to industry standards like HACCP, FSMA, and GFSI. As the first sensor-enabled magnetic separator, Intell-i-Mag® allows operators to optimize cleaning schedules, drastically reducing downtime and labor costs. It automatically tracks cleaning history and saturation trends, providing valuable insights for quality assurance. Early adopters have seen significant efficiency improvements, such as cutting cleaning stoppages by over two-thirds, leading to substantial savings. The system enhances metal control by detecting tramp metal, ensuring optimal equipment function, and facilitating compliance through automated data logging, while boosting productivity by minimizing unnecessary maintenance tasks.

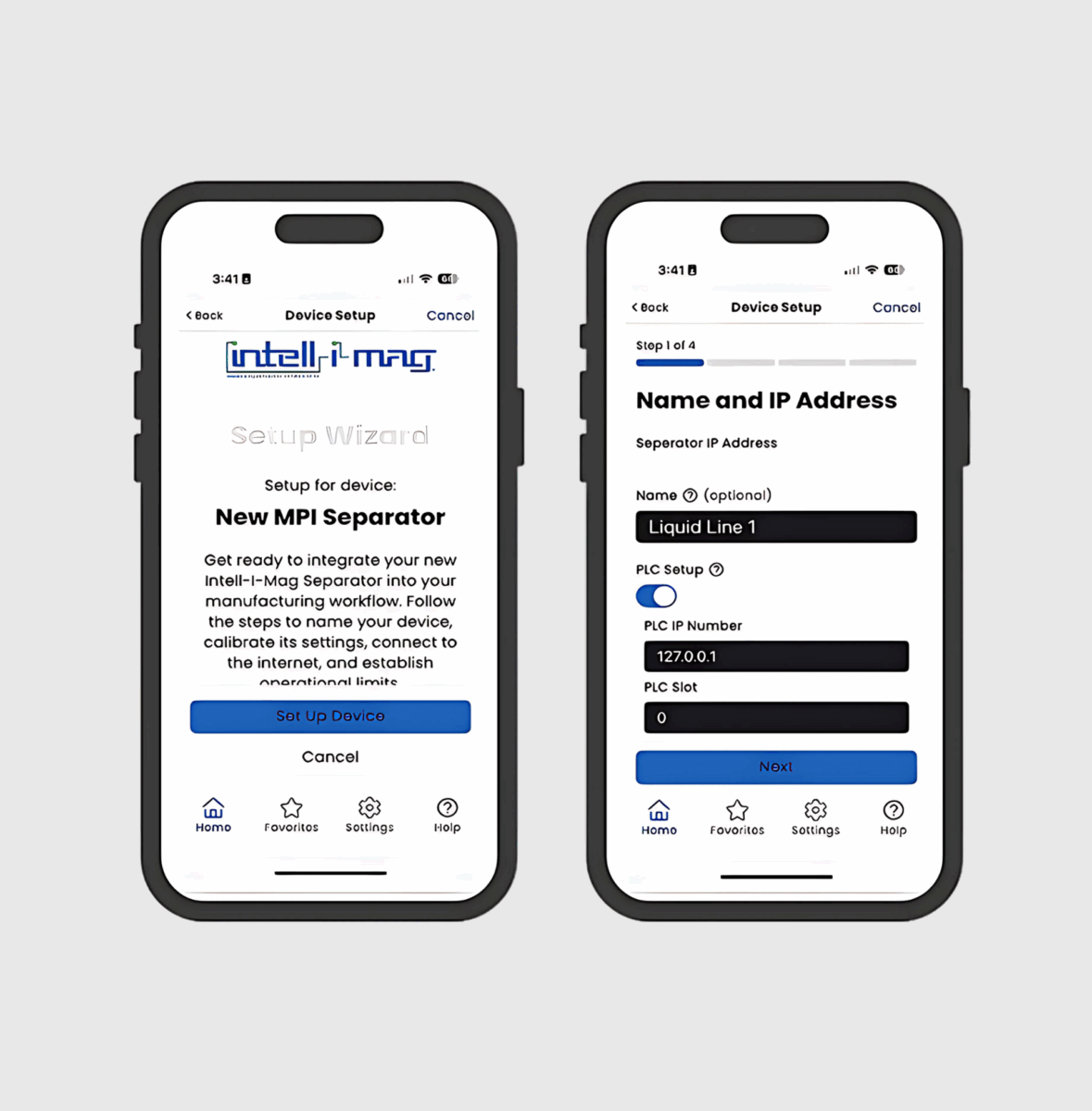

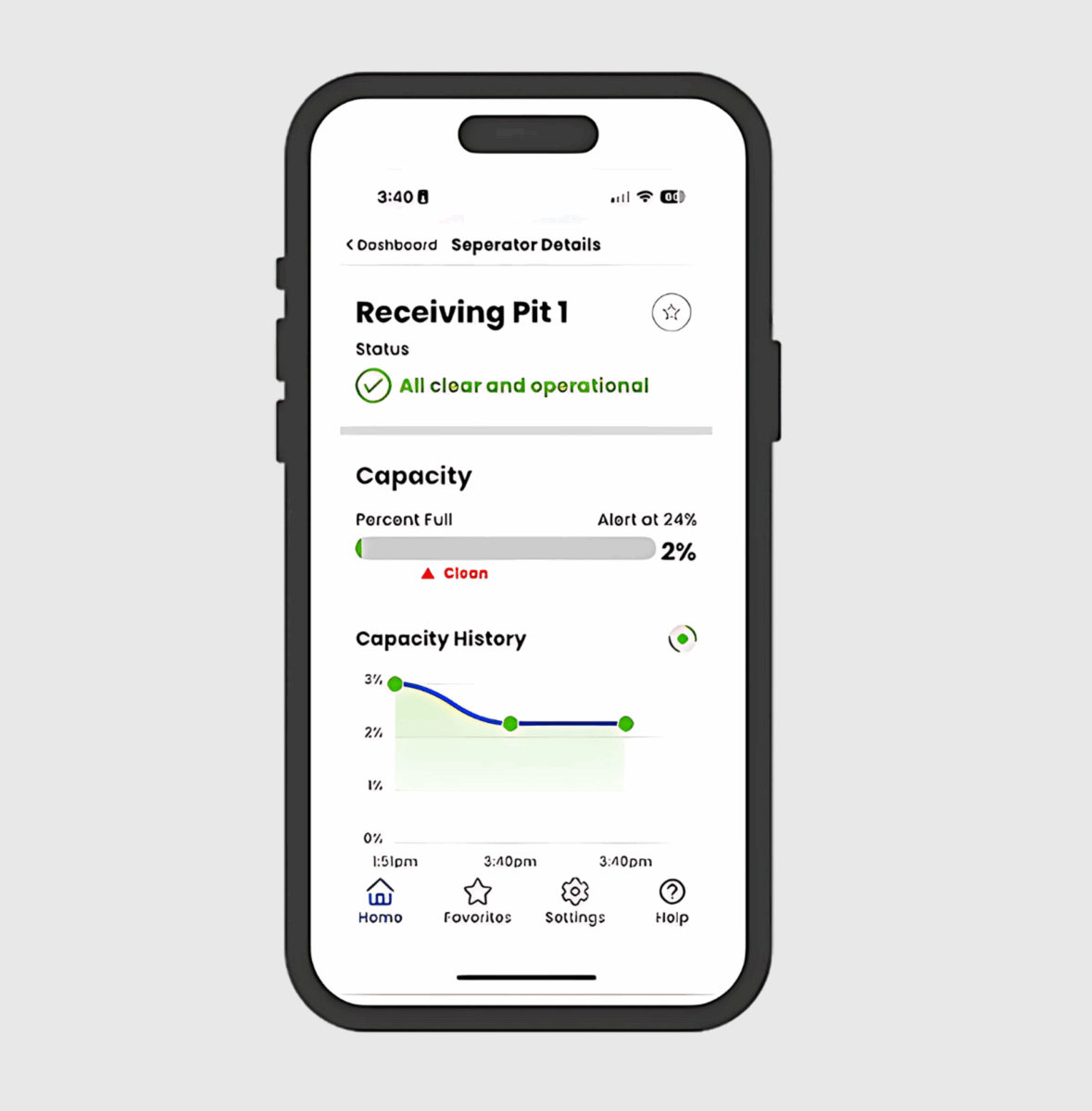

Intell-I-Mag® is an advanced sensor upgrade for magnetic separators, designed to monitor ferrous metal saturation levels in real-time. This controller, which operates independently from the magnetic separator, allows users to view saturation data through a mobile app, PLC integration, or a computer dashboard. Setup is easy via the mobile app and only takes minutes. The Intell-I-Mag® mobile app is available for both Apple and Android devices. The app facilitates configuring device settings, monitoring magnet saturation, and establishing alert thresholds. Once set up, users can access a dashboard remotely or through an HDMI-linked display. The system can be monitored and controlled via Bluetooth or Ethernet, ensuring comprehensive data visibility and integration with existing plant control systems.

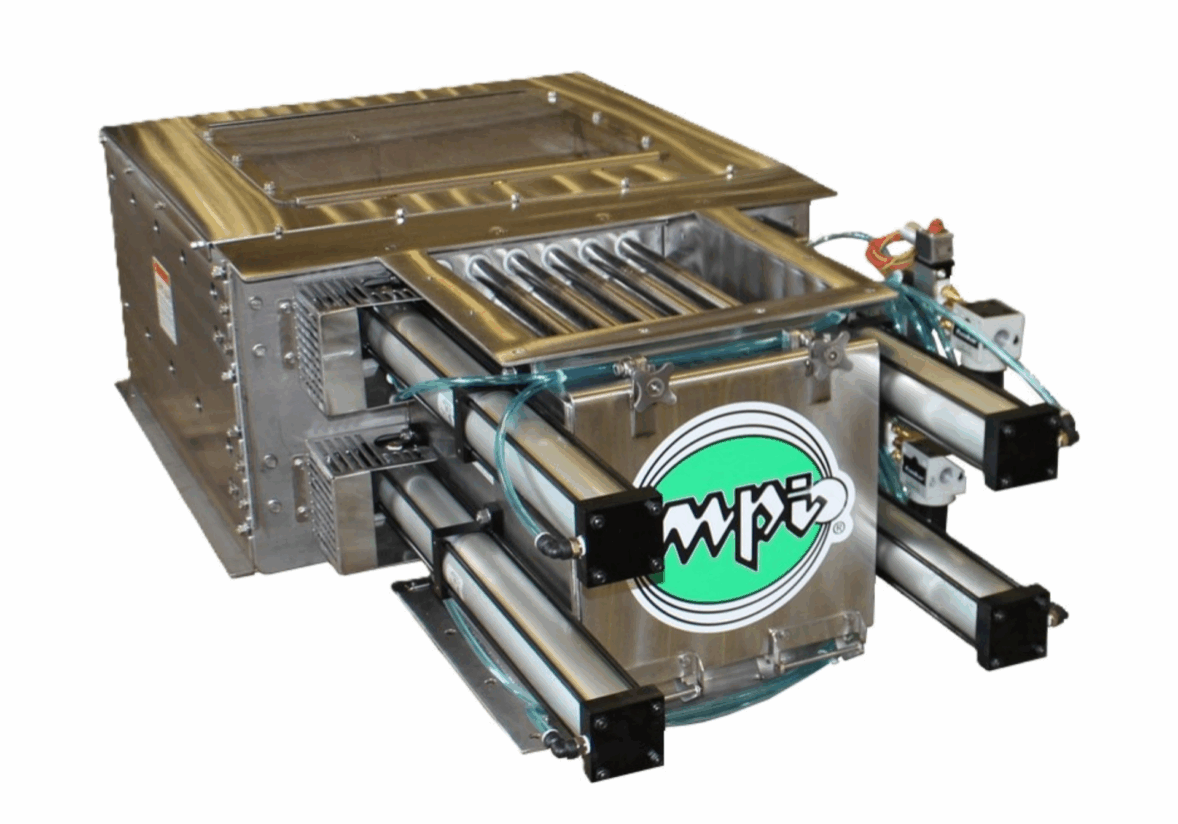

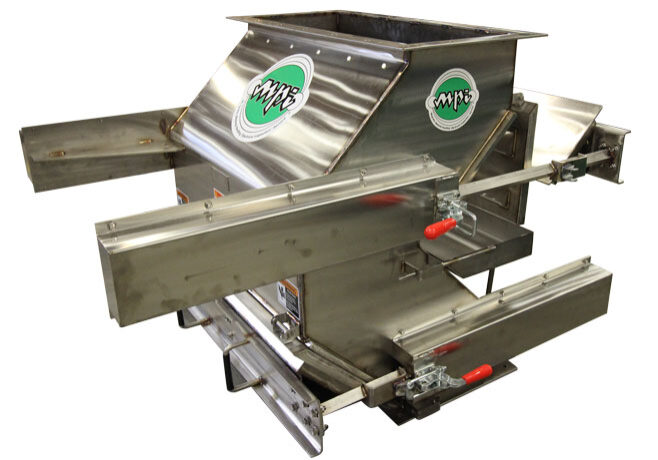

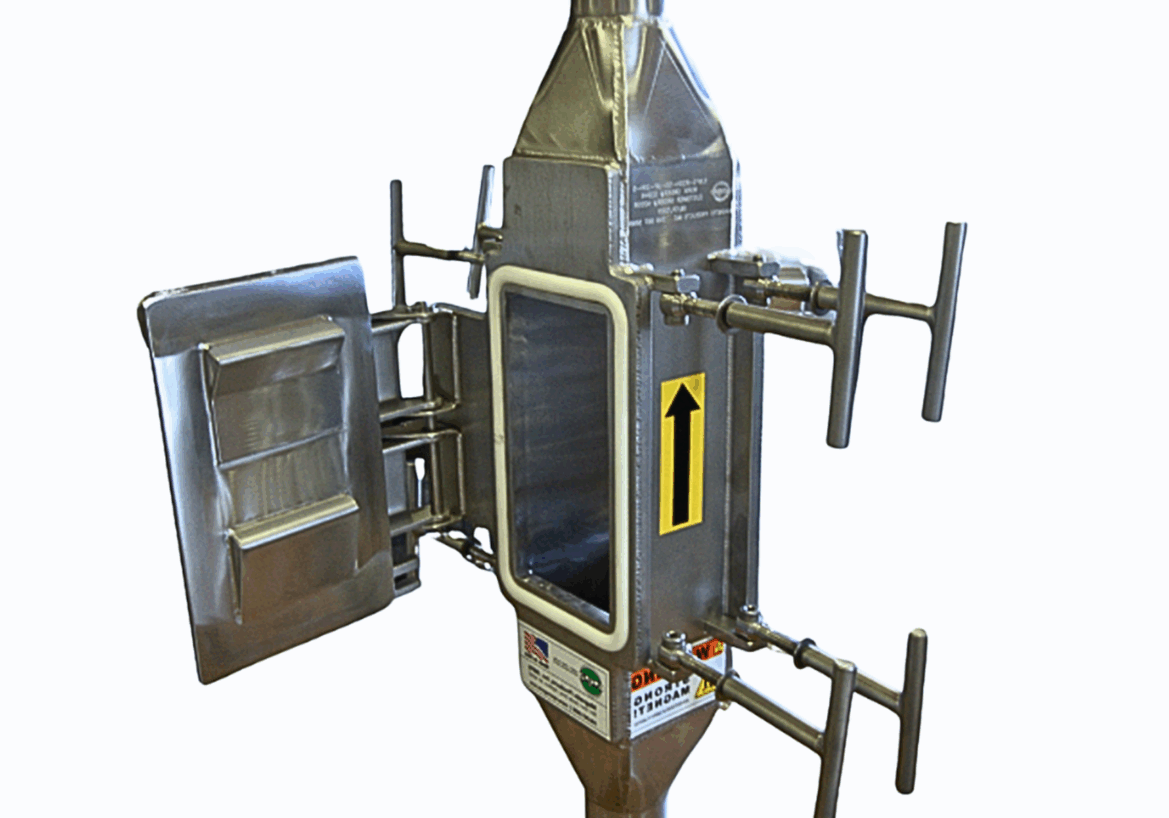

Intell-I-Mag® Compatible Products for Bulk Gravity Applications

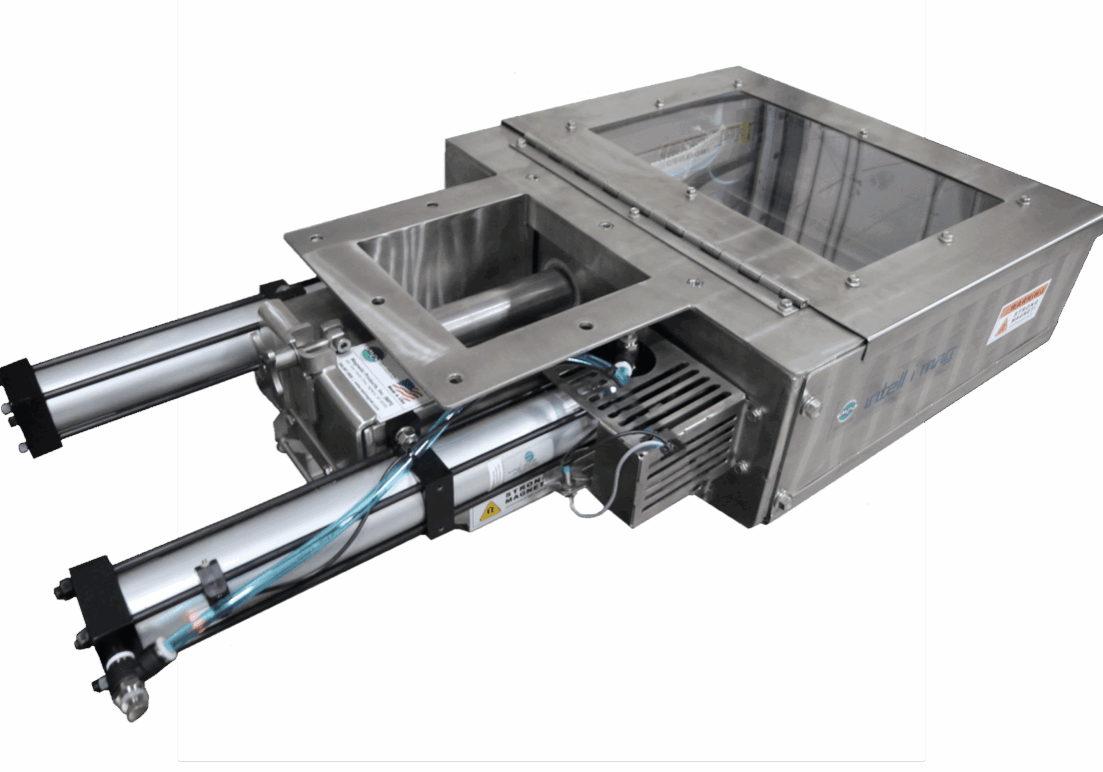

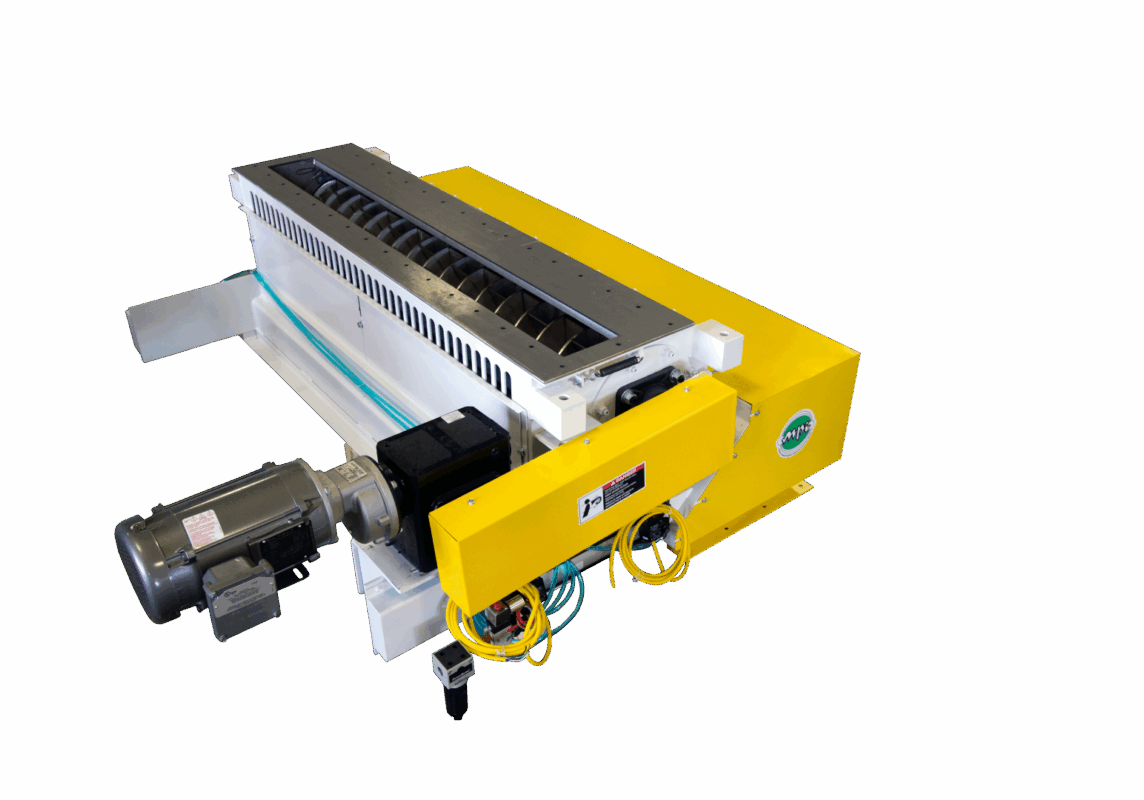

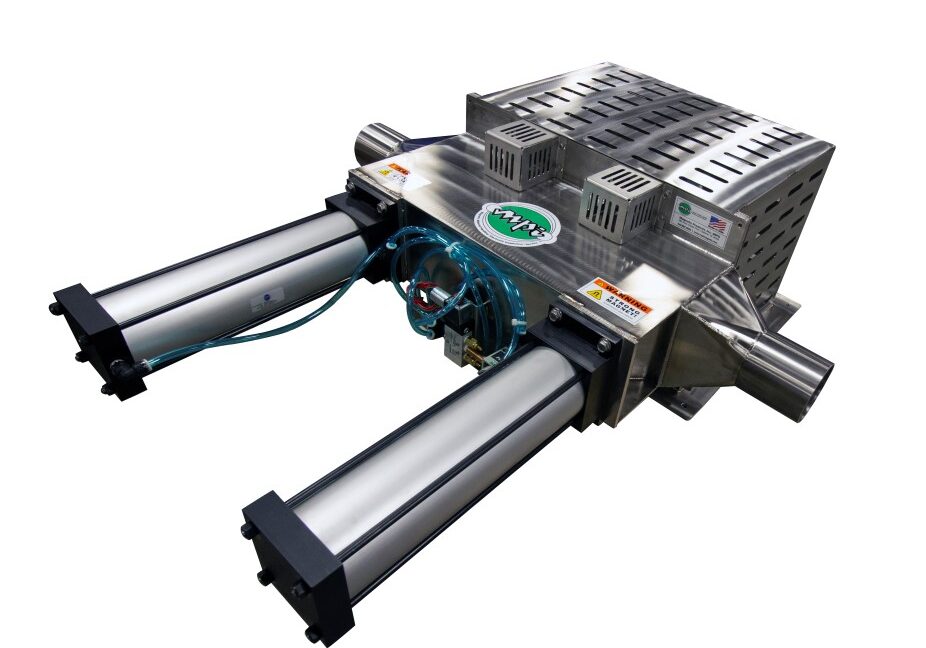

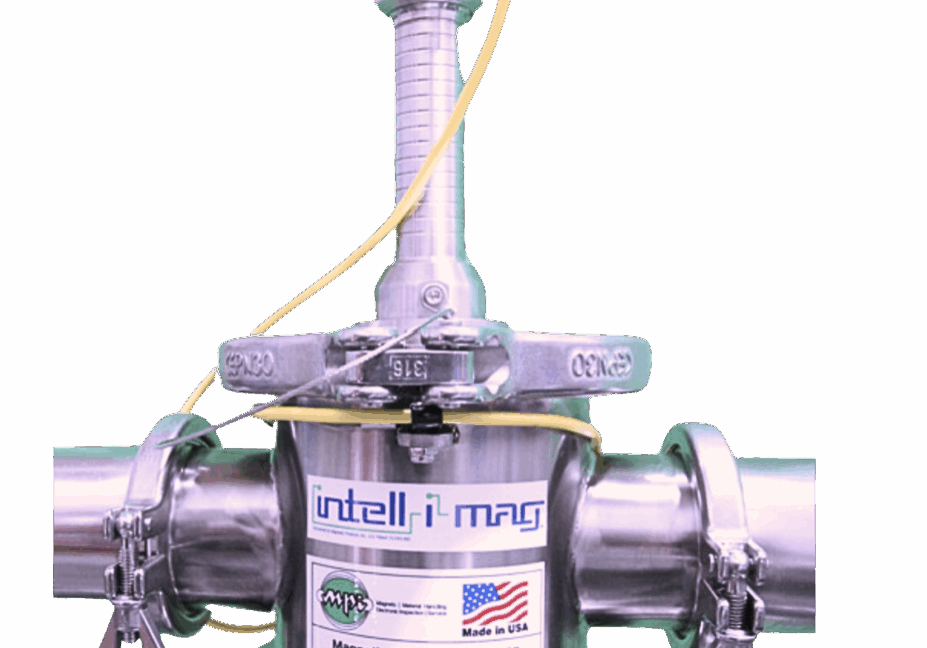

Intell-I-Mag® Compatible Products for Pneumatic Applications

Intell-I-Mag® Compatible Magnetic Separator Comparison Chart

Unique Benefits and Considerations

| Magnetic Separator Type | Applications and Uses | How Intell-I-Mag® Improves Process and Operation |

|---|---|---|

| 2" Continuous-Clean Drawer Magnet | Dry bulk material separation in food, plastics, and powder processing. | Enables continuous monitoring of magnet strength and cleaning cycle history for better audit compliance. |

| 2" Tube Self-Clean Drawer Magnet | Automated metal removal in sanitary powder conveying systems. | Automates performance tracking and reduces downtime through remote monitoring and alerts. |

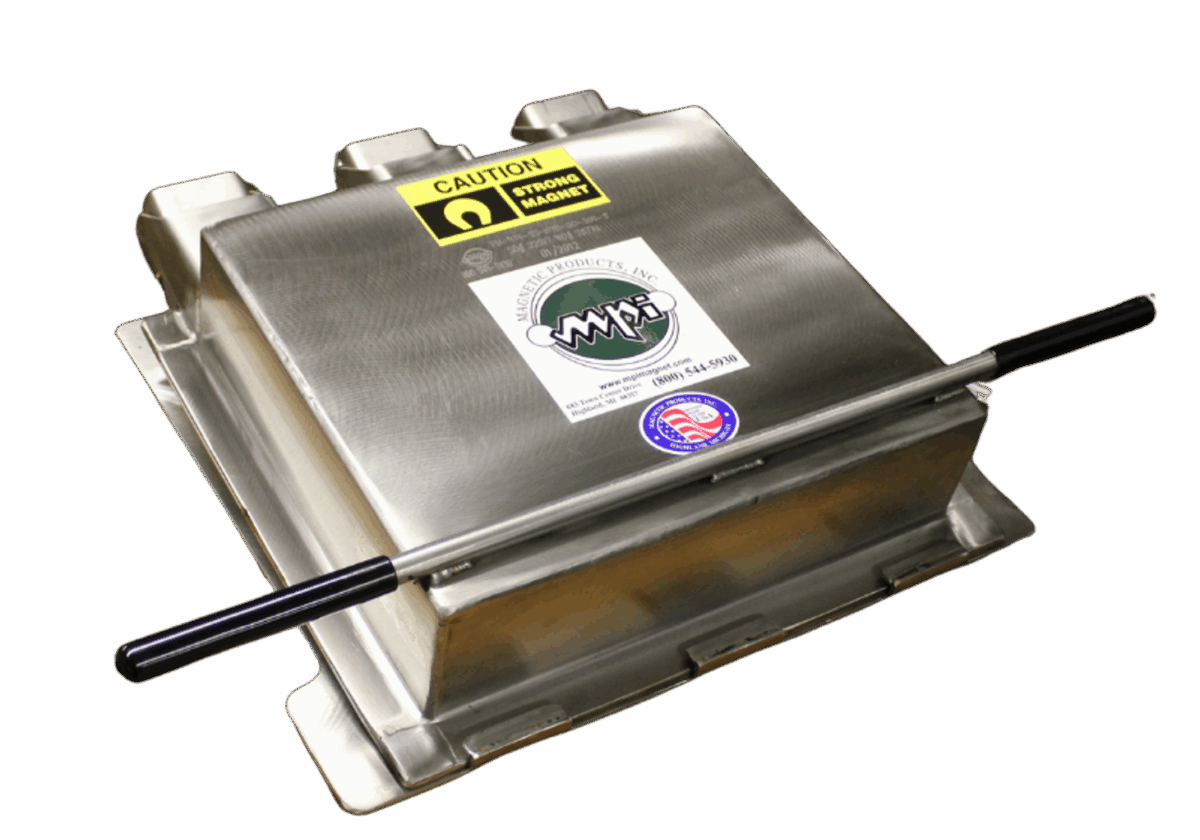

| Manual-Clean Plate Magnet | Basic tramp metal separation in bulk and gravity-fed systems. | Adds insight to cleaning frequency, alerts on performance drop, and improves QA documentation. |

| Quick-Clean Plate Magnet | Frequent-cleaning environments with moderate metal load. | Improves cleaning validation and process control visibility for FSMA/GFSI compliance. |

| Self-Clean Plate Magnet | Automated cleaning in high-volume dry material flow lines. | Fully automates tracking of cleaning intervals and system readiness, boosting uptime and safety. |

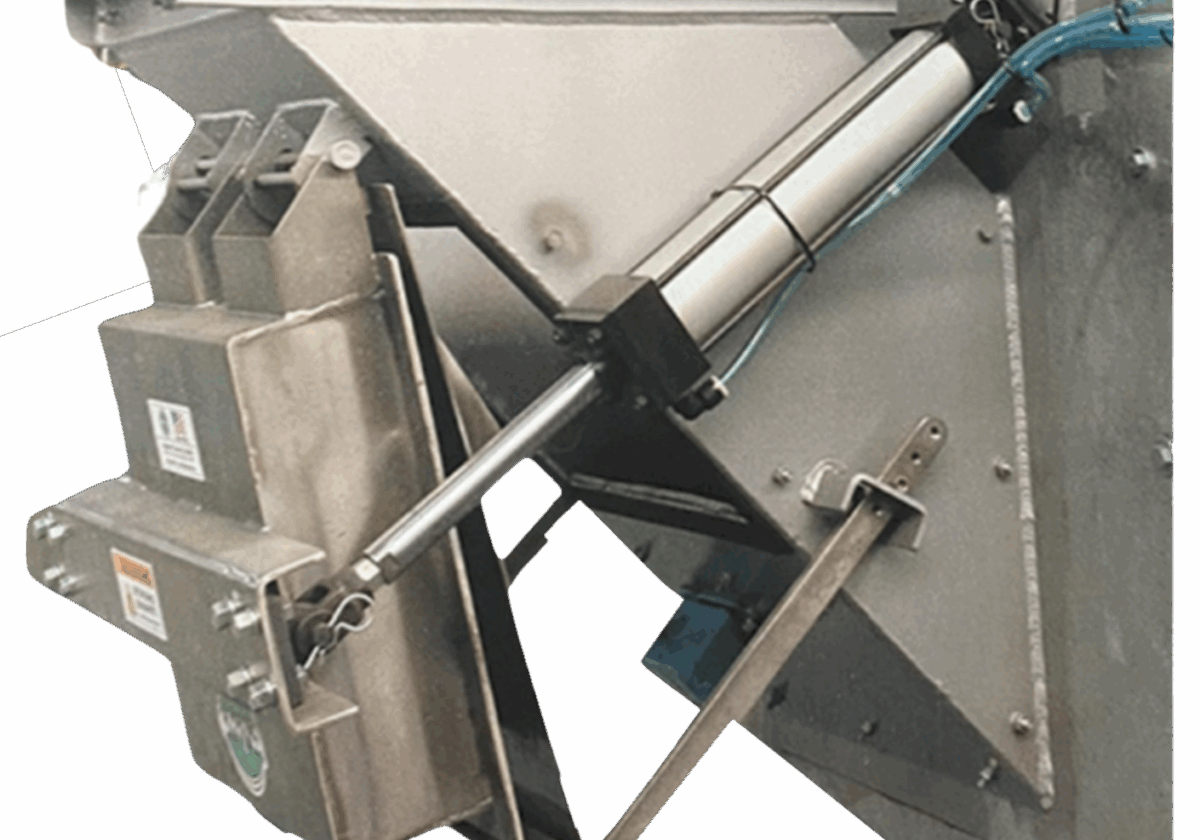

| Hump Plate Magnet | Gravity-fed material separation in tight spaces or two-direction flow. | Tracks two-stage magnet usage and wear, improving preventive maintenance and efficiency. |

| Manual-Clean Chute Magnet | General tramp metal removal in sloped gravity chutes. | Supports manual cleaning validation and traceability, improving quality control documentation. |

| Quick-Clean Chute Magnet | Tool-less access for frequent cleaning in regulated industries. | Speeds up validation logs, improves operator efficiency, reduces audit preparation time. |

| Self-Clean Chute Magnet | Hands-free metal removal in high-throughput chute systems. | Maximizes system uptime by automating cleaning tracking and process monitoring. |

| Quick-Clean Magnetic Rotary Feeder | Frequent-clean, high-precision metering of dry bulk materials in food, plastics, and pharma systems. | Enables efficient validation logging and live status checks to reduce downtime and support regulatory audits. |

| Self-Clean Magnetic Rotary Feeder | High-volume feeding and separation of powders and granules in regulated process lines. | Automatically tracks magnet saturation, cleaning intervals, and cycle history for QA visibility and predictive maintenance. |

| Wave® Self-Clean Pneumatic Line Magnet | Inline metal capture in high-velocity pneumatic transfer systems. | Delivers real-time cleaning alerts and magnetic strength tracking for critical process protection. |

| Pneumatic Tube Magnet | Low-profile magnetic protection in pneumatic conveying lines. | Improves metal capture tracking and alerts users to cleaning requirements in tight spaces. |

| Self-Clean Inline Pneumatic Drawer Magnet | Sanitary separation in high-flow pneumatic powder systems. | Enhances traceability, sanitation validation, and remote diagnostics in sanitary environments. |

| Self-Clean Plate Magnet with Housing (Inline Plate) | Inline protection of food, powder, and chemical conveying systems. | Increases safety and audit readiness through cycle tracking and maintenance alerts. |

| Quick-Clean Plate Magnet with Housing (Inline Plate) | Fast cleaning for moderately regulated pneumatic lines. | Improves magnet use accountability, especially in frequently cleaned environments. |

| Manual Plate Magnet with Housing (Inline Plate) | Cost-effective protection for light-duty inline flows. | Provides basic insight into magnet performance to support quality assurance needs. |

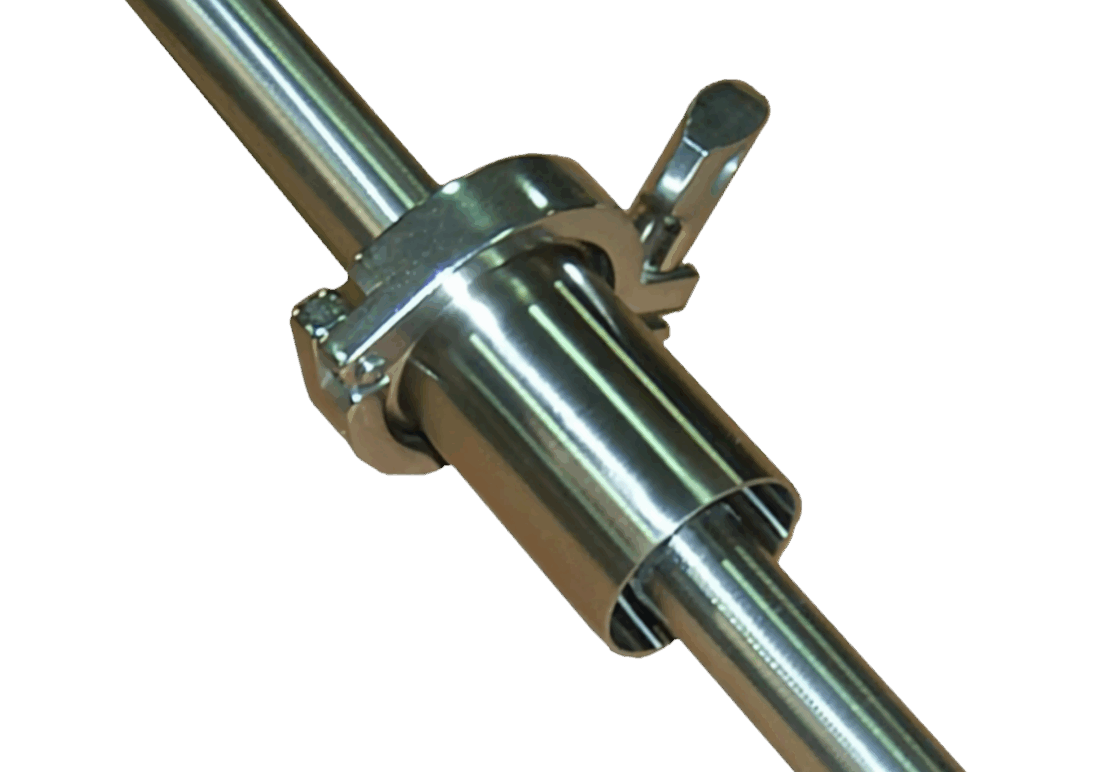

| Liquid Processing 2" Tube Blade® Magnet | Sanitary metal separation in liquid processing pipelines. | Tracks magnetic performance in liquid lines, supporting 21 CFR compliance and CIP documentation. |

Intell-I-Mag® Installation, Operation, and Benefits

For assistance in selecting the most suitable Intell-I-Mag® compatible magnet for your application or for additional customization options, contact Magnetic Products Inc. at info@mpimagnet.com today to speak with our team of experts!