Reliable and Economical Tramp Metal Capture for Gravity-Fed Chute

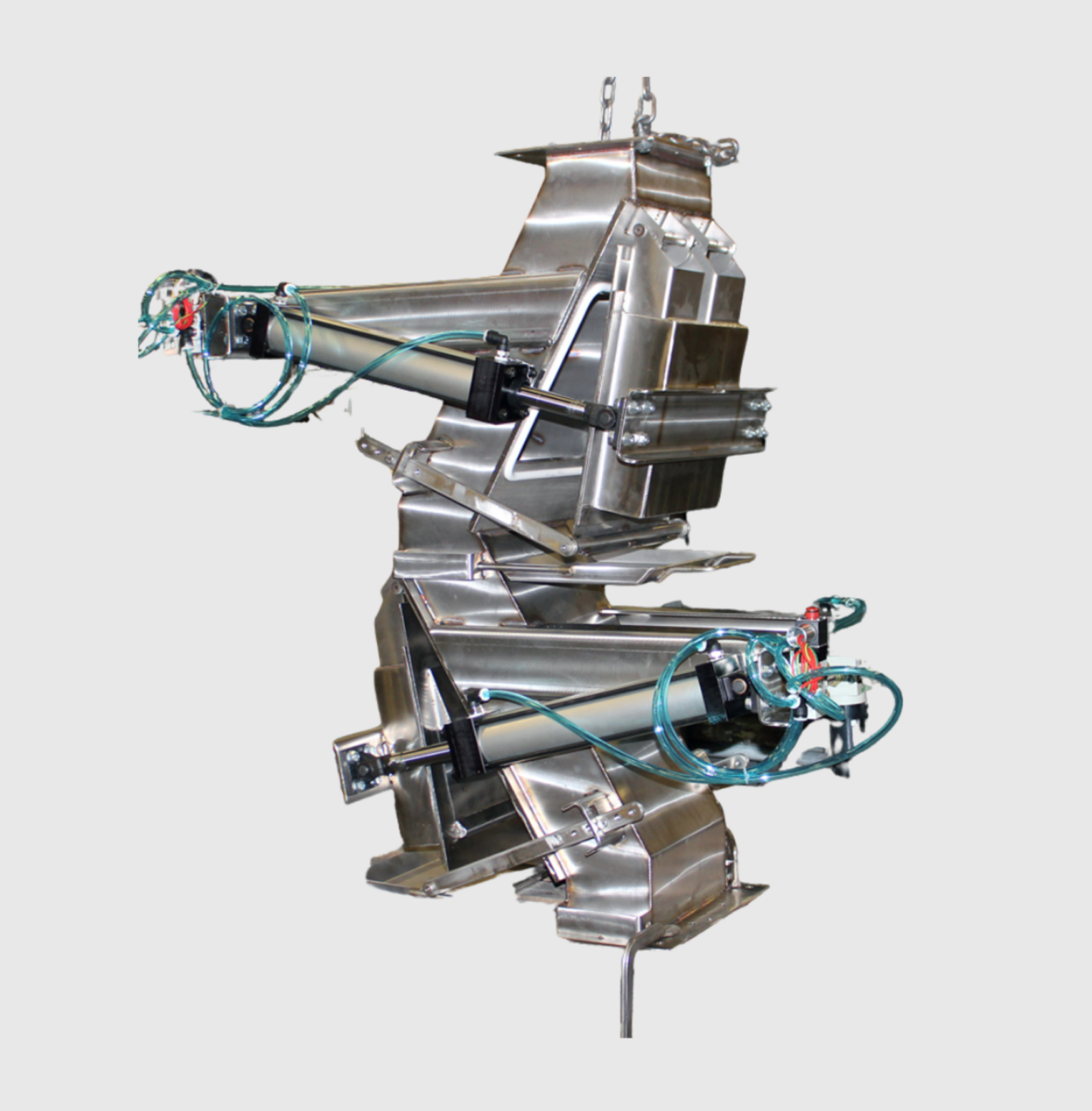

The MPI Hump Plate Magnet is designed for vertical or sloped gravity-flow chutes, where two opposing angled plate magnets ensure maximum tramp metal removal. This configuration slows material flow, increasing metal capture efficiency while minimizing wash-off, making it ideal for food, plastics, and chemical processing. Operators are responsible for manually removing the collected contaminants, which helps maintain consistent protection for processing equipment.

The MPI Hump Plate Magnet is designed for vertical or sloped gravity-flow chutes, where two opposing angled plate magnets ensure maximum tramp metal removal. This configuration slows material flow, increasing metal capture efficiency while minimizing wash-off, making it ideal for food, plastics, and chemical processing. Operators are responsible for manually removing the collected contaminants, which helps maintain consistent protection for processing equipment.

All MPI Hump Magnets are Intell-I-Mag® compatible. MPI Hump Plate Magnets are available in Manual-Clean, Quick-Clean, and Self-Clean. All cleaning mechanism types can be designed in single or double hump and with or without a replaceable abrasion-resistant feature.

Benefits of the Hump Plate Magnet From Magnetic Products, Inc

-

Enhanced Magnetic Separation

Two powerful plate magnets positioned at 90-degree angles ensure maximum tramp metal removal, improving product purity and process efficiency.

-

Minimized Downtime & Maintenance Costs

Protects processing equipment from metal contamination-related damage, reducing costly repairs and production interruptions.

-

Optimized for Various Product Flows

Efficiently handles low to high-volume materials in industries such as food, feed, grain, chemicals, and plastics.

-

Ergonomic & Easy Cleaning Options

Quick-release clamps and optional plate magnet adapters simplify contaminant removal, improving operator convenience and efficiency.

-

Customizable for Specific Needs

Available in manual-clean, quick-clean, and self-cleaning configurations, with single or double hump options to suit different applications.

-

Durable & Long-Lasting Construction

Built with dust-proof galvanized steel housing and optional abrasion-resistant features to withstand harsh industrial environments.

-

Fully Automated Cleaning Options

Self-cleaning models reduce operator intervention and labor costs, supporting continuous operation in high-volume applications.

-

Intell-I-Mag® Compatible

Integrates with MPI’s smart magnet monitoring technology for real-time performance tracking and predictive maintenance.

Hump Plate Magnet Product Details

Step-by-Step Operation

- Gravity-Fed Material Flow

- Bulk materials such as food ingredients, grains, plastics, or chemicals flow through the angled hump-shaped housing via a gravity-fed chute.

- The material passes through two powerful magnetic plate assemblies, positioned at a 90-degree angle to each other.

- Magnetic Contaminant Capture

- As the material flows through, any ferrous metal particles (e.g., iron fragments, screws, bolts, and shavings) are attracted to the high-intensity magnetic plates.

- The unique dog-leg configuration ensures maximum exposure of contaminants to the magnetic field, increasing separation efficiency.

- Durable Magnetic Capture

- Designed for high-impact and abrasive materials, such as glass, stone, and mining applications.

- The abrasion-resistant feature, including specialized coatings and hardened steel construction, ensures wear resistance and extends the service life of the magnet.

- Accumulation of Ferrous Debris

- The captured ferrous contaminants adhere to the surface of the magnetic plates, preventing them from continuing through the production line.

- This process protects downstream processing equipment from excessive wear, contamination, and possible damage.

- Cleaning Process

- For Manual-Clean Models: Operators temporarily stop the material flow, release the quick-access clamps, and manually remove metal debris from the plate magnets.

- For Quick-Clean Models: The plate magnet adapter system allows the operator to slide out the magnet effortlessly, reducing strain and heavy lifting during the cleaning cycle.

- For Self-Clean Models: The automated system uses pneumatic or mechanical mechanisms to release and dispose of captured contaminants without manual intervention.

- Resumption of Material Flow

- Once the ferrous contaminants are removed, the plate magnets are re-secured, and the product flow is resumed, ensuring seamless operation.

- The system is designed for easy installation, minimal maintenance, and long service life to keep production lines running efficiently.

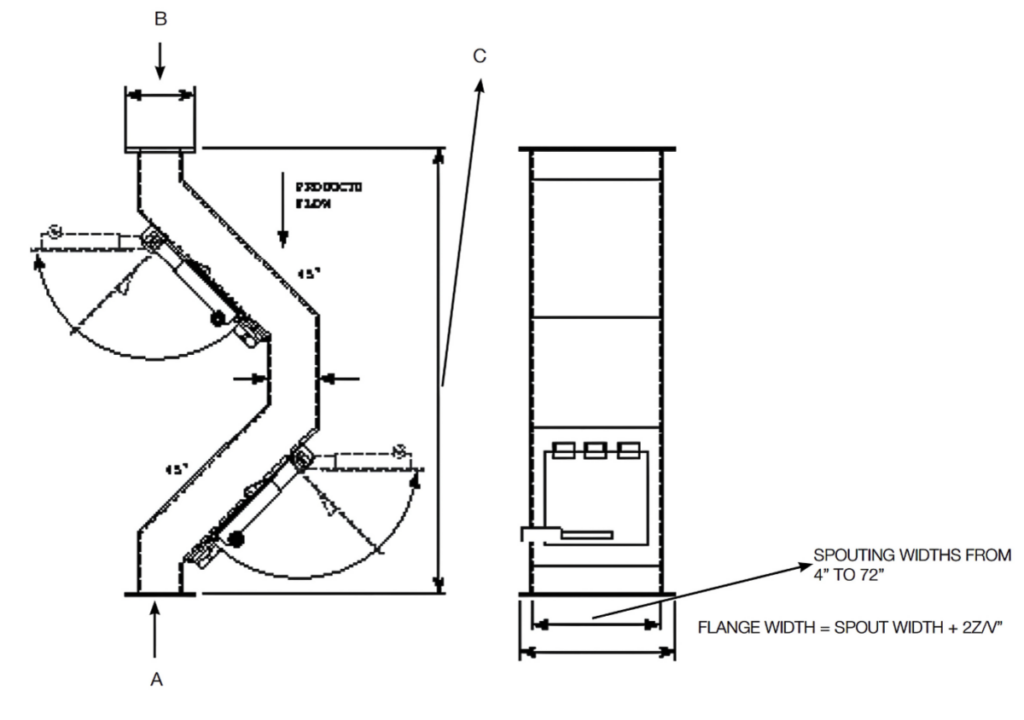

Hump Plate Magnet Specification Table

US Customary Units

| MODEL # | (A)SPOUT SIZE (IN.) | (B) FLANGE LENGTH (IN.) | (C) APPROX. OVERALL HEIGHT (IN.) | EFFECTIVE MAGNETIC FIELD DEPTH (IN.) | APPROX. UNIT WEIGHT (LBS.) |

|---|---|---|---|---|---|

| MH-300 | 6 | 8.25 | 30 | 3 | 236 |

| MH-400 | 6 | 8.25 | 42 | 5 | 276 |

| MH-500 | 8 | 10.25 | 42 | 8 | 346 |

| MH-600 | 10 | 16.25 | 52 | 10 | 486 |

Compatibility Check - Hump Plate Magnet Installations

Manual-Clean Hump Magnet with Abrasion-Resistant Plate and Coating

Single Hump Quick-Clean Hump Magnet with Custom Angle

Self-Clean Hump Magnet Designed for Narrow Chute and Processing Line