Effortless Cleaning for Gravity-Fed Material Flow

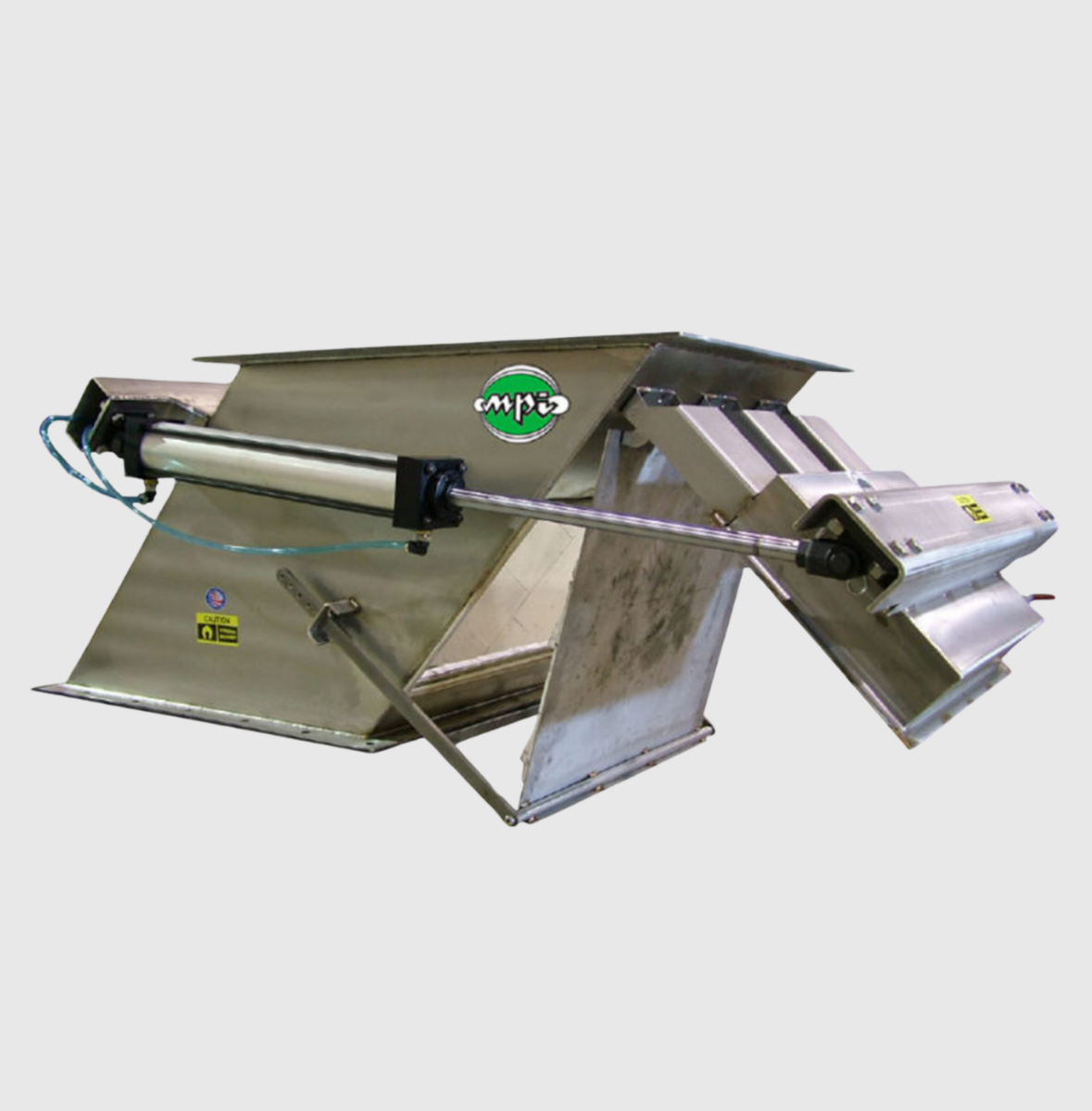

The MPI Self-Clean Plate Magnet provides fully automated metal separation for continuous operation in high-volume processing environments. Using a pneumatically controlled cleaning system, the self-cleaning plate magnet automatically removes collected contaminants at timed intervals, ensuring uninterrupted production and minimal maintenance.

The Self-Clean Plate Magnet is engineered for applications requiring automatic contaminant removal. Using a pneumatically or mechanically operated system, this magnet eliminates manual cleaning and ensures continuous operation. Self-Clean Plate magnets with Intell-I-Mag® are the most efficient and reliable material handling and contamination control plate magnet solution on the market. They help industries improve workflow efficiency, reduce equipment damage, maintain high product purity, and ensure regulatory compliance.

Benefits of the Self-Clean Plate Magnet From Magnetic Products, Inc

-

Automatic Self-Cleaning Mechanism

The self-cleaning system automatically removes captured ferrous contaminants, reducing manual labor and improving operational efficiency. By periodically discharging metal debris, this feature ensures continuous magnetic separation without requiring operator intervention. Ideal for high-volume or heavily contaminated product streams, where frequent cleaning is necessary to maintain peak performance.

-

Powerful Magnetic Separation

With high-intensity rare-earth or ceramic magnets, MPI Self-Clean Plate Magnets efficiently capture fine and large ferrous particles. The strong magnetic field extends deep into the product stream, ensuring comprehensive separation in gravity-fed, pneumatic, and conveyor applications. Prevents even the smallest metal fragments from entering processing lines, ensuring product purity and compliance with industry regulations.

-

Durable & Sanitary Stainless-Steel Construction

Constructed from heavy-duty stainless steel, ensuring long-lasting durability and corrosion resistance even in harsh processing environments. Meets food-grade and sanitary standards for food processing, pharmaceuticals, and chemical manufacturing industries. Resists wear and tear, making it a low-maintenance and cost-effective investment for long-term use.

-

Minimal Downtime & Reduced Maintenance

The self-cleaning functionality eliminates frequent manual intervention, significantly reducing system downtime. Operators can focus on production tasks rather than stopping operations for cleaning, increasing overall process efficiency. It also reduces the risk of human error in metal contamination removal, ensuring consistent and reliable performance.

-

Easy Integration & Flexible Mounting Options

The system offers seamless integration into existing processing lines, with customizable options for chutes, conveyors, ducts, and gravity-fed systems. Its various sizes and strengths allow tailored solutions based on specific material flow rates and contamination levels. Installation is made easy with pre-fitted hinges, latches, and mounting hardware, ensuring a secure and stable fit in any processing setup.

-

Protects Equipment & Prevents Costly Repairs

The system effectively captures and eliminates tramp metal, iron filings, nuts, bolts, and other contaminants before they can damage grinders, crushers, mills, or extruders. By preventing equipment damage and unexpected breakdowns, it enhances the longevity of essential processing machinery. This risk reduction minimizes downtime and production stoppages, maximizing operational efficiency and cost savings.

-

Enhances Product Purity & Regulatory Compliance

Preventing metal contamination is essential for manufacturers to comply with stringent industry standards like FDA, USDA, HACCP, and GMP. This practice ensures high-quality production in food, pharmaceuticals, plastics, and bulk materials, safeguarding brand reputation and customer trust. Additionally, addressing metal contamination mitigates safety hazards and lowers the likelihood of product recalls.

-

Ideal for High-Volume & Heavy-Contamination

It is perfect for industries handling large material volumes or processing materials prone to metal contamination, such as recycling, mining, plastics, agriculture, and bulk powders. It is designed to withstand continuous operation in demanding environments, maintaining peak magnetic performance over extended periods. It ensures reliable contamination control in fast-moving product streams, improving overall production efficiency.

Self-Clean Plate Magnet Product Details

Magnetic Separation Process

MPI’s Manual Clean Plate Magnets utilize high-intensity magnetic fields to capture and retain ferrous contaminants as materials pass over their surface. These magnets are engineered to protect downstream equipment and preserve product integrity in various bulk material handling scenarios.

- Material Flow & Magnetic Attraction: As the product moves across the plate magnet, ferrous contaminants (including iron filings, metal shavings, and tramp metal) are attracted and securely retained on the magnet’s surface.

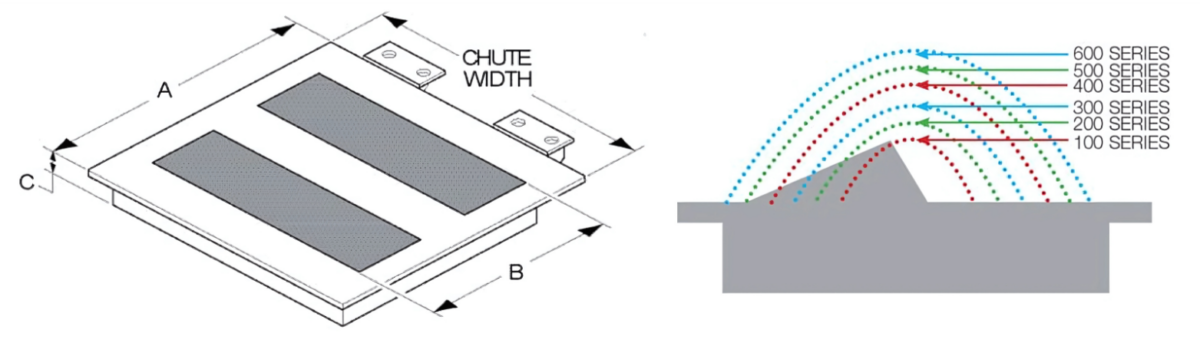

- Single Step & Double Step Design:

- Single Step Plate Magnets slightly divert the product stream, ensuring contaminants are drawn away from the primary material flow.

- Double-step plate Magnets provide an enhanced separation mechanism, creating additional trapping points for contaminants and facilitating the removal of finer metal debris.

- Optimized Magnetic Holding Power: Utilizing Magnetic 400 series stainless steel pole areas enhances magnetic efficiency, ensuring that even the smallest ferrous particles adhere firmly to the magnet's surface.

- Sanitary & Easy Installation: MPI Plate Magnets come equipped with hinges, latches, and mounting hardware, making for quick and secure installation in existing processing lines. The hinged mounting system allows for easy access during maintenance and cleaning.

- Effective in Deep Product Streams: The strong magnetic field penetrates product flows up to 8 inches deep, making it suitable for bulk material processing applications where contamination control is essential.

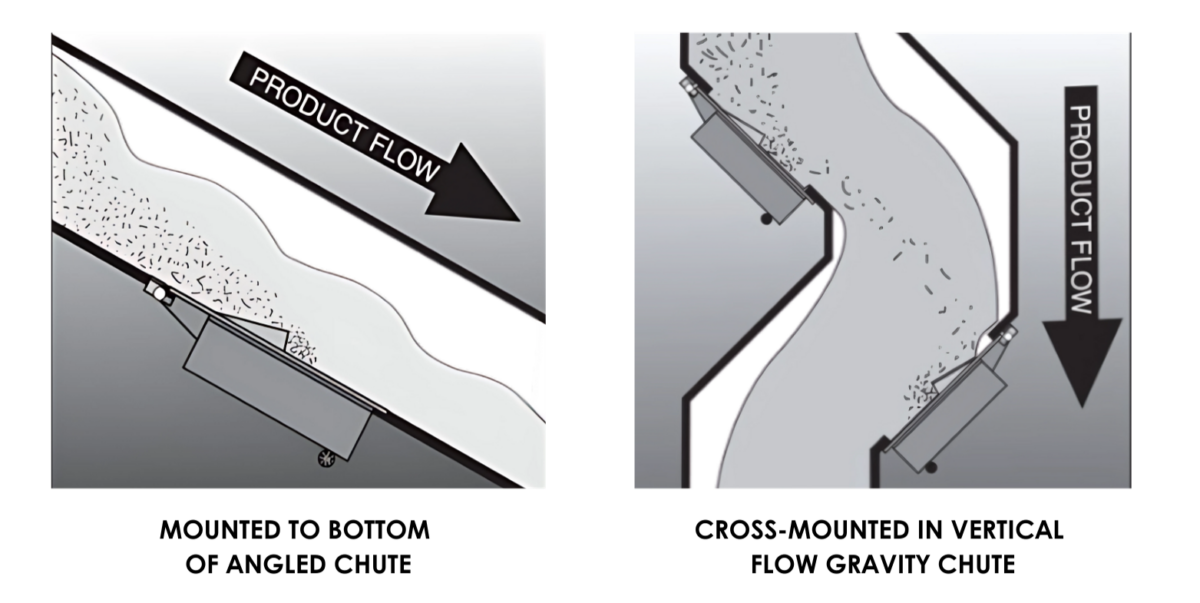

Versatile Mounting & Placement

Versatile Mounting & Placement

MPI Manual Clean Plate Magnets are designed for flexible installation, ensuring optimal separation efficiency across multiple processing environments:

- Above Conveyor Belts: Mounted over material flow to capture ferrous contaminants before they reach grinders, crushers, or downstream equipment.

- Inside Chutes or Hoppers: Installed within gravity-fed or pneumatic transfer systems to eliminate tramp metal from bulk materials.

- Inline Processing Applications: Positioned within product flow paths to avert metal contamination in food processing, recycling, plastics, and pharmaceutical industries.

Cleaning Process

Automated Contaminant Capture – Ferrous materials are pulled from the material flow and retained by the plate magnet.

Pneumatic Cleaning System – The self-cleaning mechanism automatically removes and discharges contaminants at scheduled intervals without stopping material flow.

- Contaminated material flows over the magnetic plate, where metal particles are captured.

- The automated cleaning cycle activates mechanically removing contaminants.

- Collected debris is directed into a disposal bin for easy waste management.

Self-Clean Plate Magnet Specification Table

US Customary Units

| PLATE MAGNET MODEL # | (A) OVERALL LENGTH (IN) | (B) MAGNET LENGTH (IN.) | (C) THICKNESS (IN.) | STEP HEIGHT (IN.) | FIELD DEPTH (IN.) | APPROX. WEIGHT PER FT. OF CHUTE WIDTH (LBS.) |

|---|---|---|---|---|---|---|

| MP-100 | 7.5 | 5.5 | 1 | 0.50 | 1 | 14 |

| MP-200 | 8.5 | 6.5 | 1.5 | 0.63 | 2 | 20 |

| MP-300 | 10.5 | 8.5 | 2.12 | 0.81 | 3 | 40 |

| MP-400 | 12.5 | 10.5 | 2.75 | 1.00 | 5 | 60 |

| MP-500 | 15.5 | 13.5 | 4.25 | 1.50 | 8 | 96 |

| MP-600 | 18.5 | 16.5 | 6.5 | 1.68 | 10 | 165 |

Self-Clean Plate Magnet Installations & Variations

Self-Clean Plate Magnet Designed for Large Recycling Facility

Custom Self-Clean Plate Magnet for High-Volume Corn Processing

Self-Clean Plate Magnet Specified for Mineral Granulate Application