Designed For Gravity-Fed Angled Chutes

The MPI Manual Clean Plate Magnet provides cost-effective, high-intensity ferrous metal separation for gravity-fed or conveyor systems. Installed over material flow areas, this permanent plate magnet captures tramp metal, including nails, bolts, and shavings. Operators manually remove collected contaminants, ensuring consistent protection of processing equipment. MPI Manual-Clean Plate Magnets are Intell-I-Mag® compatible.

The Manual-Clean Plate Magnet is a simple, cost-effective solution for removing ferrous contaminants from free-flowing materials. Designed for gravity-fed systems, this magnet is ideal for protecting processing equipment from damage caused by metal debris. The manual-cleaning mechanism requires operators to physically remove accumulated ferrous particles, making it best suited for applications with moderate contamination levels.

Benefits of the Manual-Clean Plate Magnet From Magnetic Products, Inc

-

High-Intensity Magnetic Field

Efficient metal capture utilizes a strong magnetic field to effectively trap both fine and large ferrous contaminants, such as iron filings, rust, nails, and metal fragments. This technology is advantageous for industries like food processing, pharmaceuticals, and plastics, where material purity is crucial. It ensures consistent performance, providing long-term efficacy in removing metal contaminants from free-flowing materials in chutes, conveyors, and ducts.

-

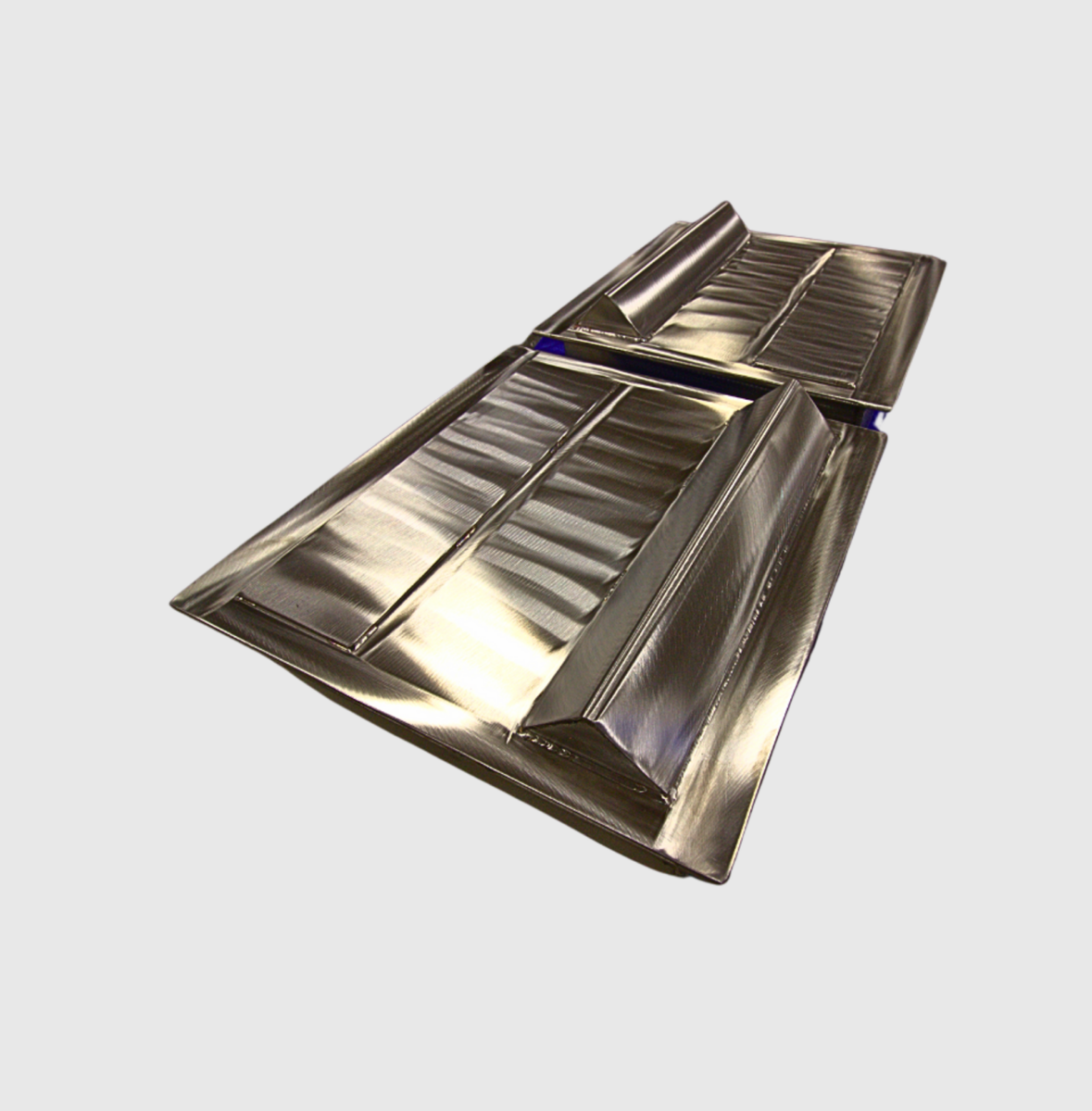

Durable Stainless-Steel Construction

The product is made from high-grade stainless steel, ensuring exceptional durability against corrosion, rust, and wear, even in harsh environments. It meets industry hygiene and safety standards, making it suitable for food, pharmaceutical, and chemical processing while complying with FDA, USDA, and GMP regulations. Additionally, it is designed for high-impact applications, making it ideal for industries that handle abrasive materials like mining, cement, and bulk material processing.

-

Simple Cleaning Mechanism

The system provides user-friendly maintenance, enabling operators to quickly remove metal debris without intricate automation and with minimal downtime. It maintains reliable performance in tough conditions such as dust, high moisture, and high temperatures, where automated systems may fail. Furthermore, it is cost-effective, reducing maintenance costs while ensuring ongoing protection for downstream equipment.

-

Versatile Installation

The product features flexible integration, allowing it to be mounted in various systems like chutes, ducts, and conveyors without significant modifications. It comes in customizable configurations with different sizes and strengths to meet diverse processing line needs. This versatility makes it suitable for multiple industries, including food processing, plastics, recycling, agriculture, and bulk material handling.

-

Cost-Effective Solution

This solution operates without electricity, making it energy-efficient and cost-effective. It incurs minimal maintenance costs, needing only routine cleaning due to the absence of moving parts or complex components. With a durable design, it offers a long service life and ensures a high return on investment.

-

Prevents Equipment Damage

The system safeguards essential machinery by preventing metal contaminants from harming equipment such as grinders, crushers, mills, extruders, and packaging machines. This leads to reduced downtime and repairs, minimizing unexpected breakdowns and enhancing overall equipment efficiency. Additionally, it improves workplace safety by stopping hazardous metal fragments from entering processing lines, which lowers the risks of sparks, fires, and product recalls.

Manual-Clean Plate Magnet Product Details

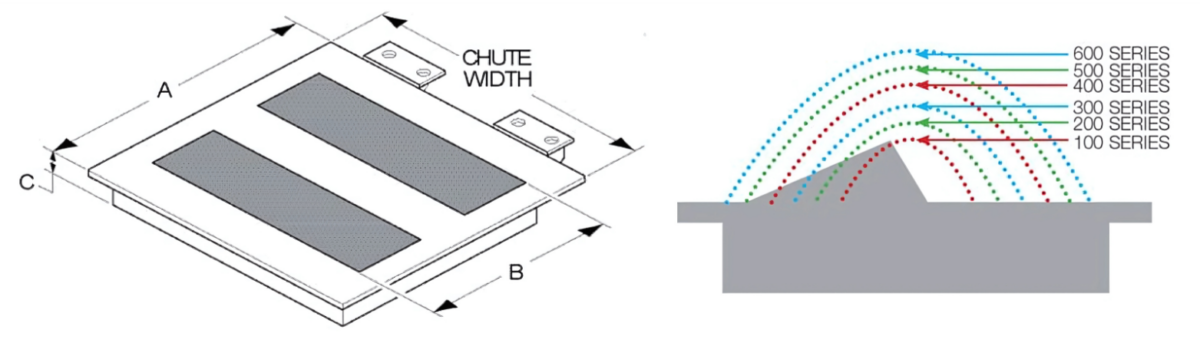

Magnetic Separation Process

MPI’s Manual Clean Plate Magnets utilize high-intensity magnetic fields to capture and retain ferrous contaminants as materials pass over their surface. These magnets are engineered to protect downstream equipment and preserve product integrity in various bulk material handling scenarios.

- Material Flow & Magnetic Attraction: As the product moves across the plate magnet, ferrous contaminants (including iron filings, metal shavings, and tramp metal) are attracted and securely retained on the magnet’s surface.

- Single Step & Double Step Design:

- Single Step Plate Magnets slightly divert the product stream, ensuring contaminants are drawn away from the primary material flow.

- Double-step plate Magnets provide an enhanced separation mechanism, creating additional trapping points for contaminants and facilitating the removal of finer metal debris.

- Optimized Magnetic Holding Power: Utilizing Magnetic 400 series stainless steel pole areas enhances magnetic efficiency, ensuring that even the smallest ferrous particles adhere firmly to the magnet's surface.

- Sanitary & Easy Installation: MPI Plate Magnets come equipped with hinges, latches, and mounting hardware, making for quick and secure installation in existing processing lines. The hinged mounting system allows for easy access during maintenance and cleaning.

- Effective in Deep Product Streams: The strong magnetic field penetrates product flows up to 8 inches deep, making it suitable for bulk material processing applications where contamination control is essential.

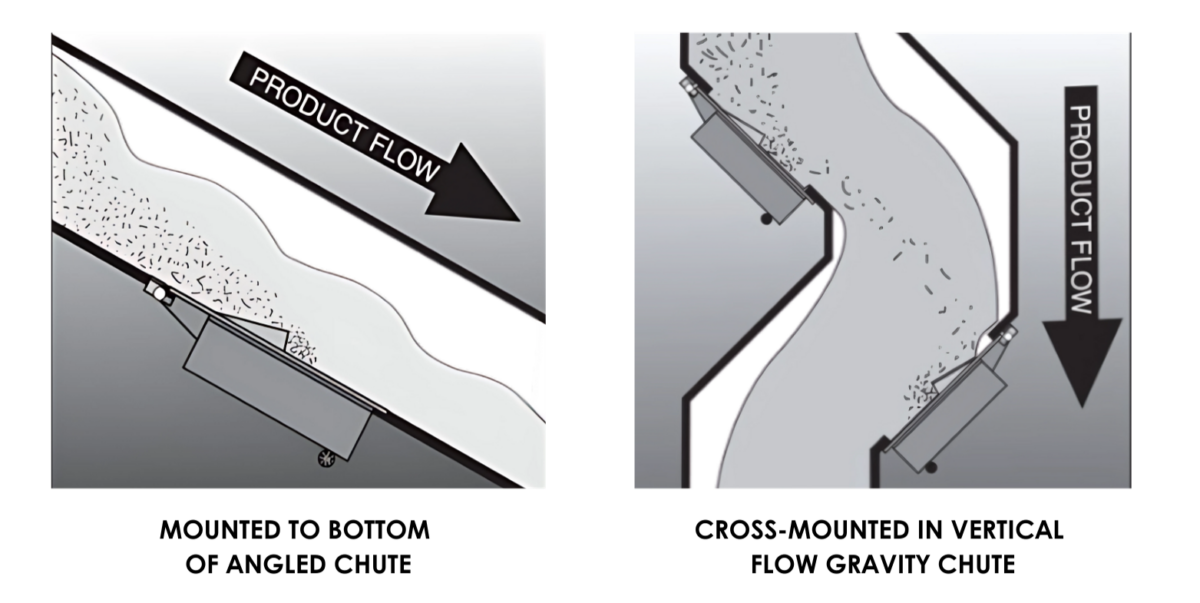

Versatile Mounting & Placement

Versatile Mounting & Placement

MPI Manual Clean Plate Magnets are designed for flexible installation, ensuring optimal separation efficiency across multiple processing environments:

- Above Conveyor Belts: Mounted over material flow to capture ferrous contaminants before they reach grinders, crushers, or downstream equipment.

- Inside Chutes or Hoppers: Installed within gravity-fed or pneumatic transfer systems to eliminate tramp metal from bulk materials.

- Inline Processing Applications: Positioned within product flow paths to avert metal contamination in food processing, recycling, plastics, and pharmaceutical industries.

Cleaning Process

To maintain magnetic efficiency and prevent buildup, operators should regularly remove accumulated contaminants from the magnet surface. MPI’s Manual Clean Plate Magnets offer two cleaning methods, depending on the specific model:

- Operators can manually remove or brush off metal contaminants from the magnet surface.

- The hinged mounting system ensures easy access, minimizing downtime during maintenance.

- This method is ideal for applications where cleaning frequency is lower, or contamination levels are moderate.

Manual-Clean Plate Magnet Specification Table

US Customary Units

| PLATE MAGNET MODEL # | (A) OVERALL LENGTH (IN) | (B) MAGNET LENGTH (IN.) | (C) THICKNESS (IN.) | STEP HEIGHT (IN.) | FIELD DEPTH (IN.) | APPROX. WEIGHT PER FT. OF CHUTE WIDTH (LBS.) |

|---|---|---|---|---|---|---|

| MP-100 | 7.5 | 5.5 | 1 | 0.50 | 1 | 14 |

| MP-200 | 8.5 | 6.5 | 1.5 | 0.63 | 2 | 20 |

| MP-300 | 10.5 | 8.5 | 2.12 | 0.81 | 3 | 40 |

| MP-400 | 12.5 | 10.5 | 2.75 | 1.00 | 5 | 60 |

| MP-500 | 15.5 | 13.5 | 4.25 | 1.50 | 8 | 96 |

| MP-600 | 18.5 | 16.5 | 6.5 | 1.68 | 10 | 165 |

Manual-Clean Plate Magnet Installations & Variations

Manual-Clean Plate Magnet Designed with a Jump Step

Manual-Clean Plate Magnet with a Custom Lid Loop

Manual-Clean Plate Magnet Installed on a Cattle Feed Trailer