Chute Magnets are engineered to extract medium to large-sized ferrous tramp iron contaminants from gravity-fed vertical chutes with high-volume product streams, such as those used for grain, chemicals, food, and powders. Available options include Manual Clean Chute Magnets, Quick Clean Chute Magnets, and Self-Clean Chute Magnets.

Drawer Magnets feature tiers of magnetic tubes to eliminate medium and small-sized ferrous tramp metal contaminants. The range includes Manual, Quick, and Self-Clean models, Carbon and Stainless-Steel Drawer Magnets, Continuous Flow Drawer Magnets, large tube drawer magnets, Round Spout Drawer Magnets, Sanitary Toolless Drawer Magnets, and 2-inch Tube Drawer Magnets.

Feeder Magnets are intended to safeguard and regulate the feeding characteristics of free-flowing materials positioned above hammer mills as they enter processing equipment. Magnetic rotary feeders are among the available products. These magnets effectively manage the flow of materials, ensuring optimal operation and protection in processing systems.

Free-flow magnets are engineered to capture both large and small tramp metal in high-volume, abrasive, gravity-fed product streams. The Quick Clean Free-Flow Magnets are specifically suited for vertical product streams in the grain and mining sectors, while Self-Clean Free-Flow Magnets effectively collect tramp metal in vertical chutes and feature a pneumatically operated cleaning mechanism for easy maintenance.

Grate Magnets are designed to eliminate medium- and small-sized ferrous tramp metal contaminants from dry, granular products in gravity-fed systems like chutes, hoppers, and bins. Magnetic Tubes serve a similar purpose by effectively removing ferrous metal from both dry and liquid products, often caused by metal-on-metal wear or other contamination. This category encompasses both Ceramic and Rare-Earth Tube Magnets.

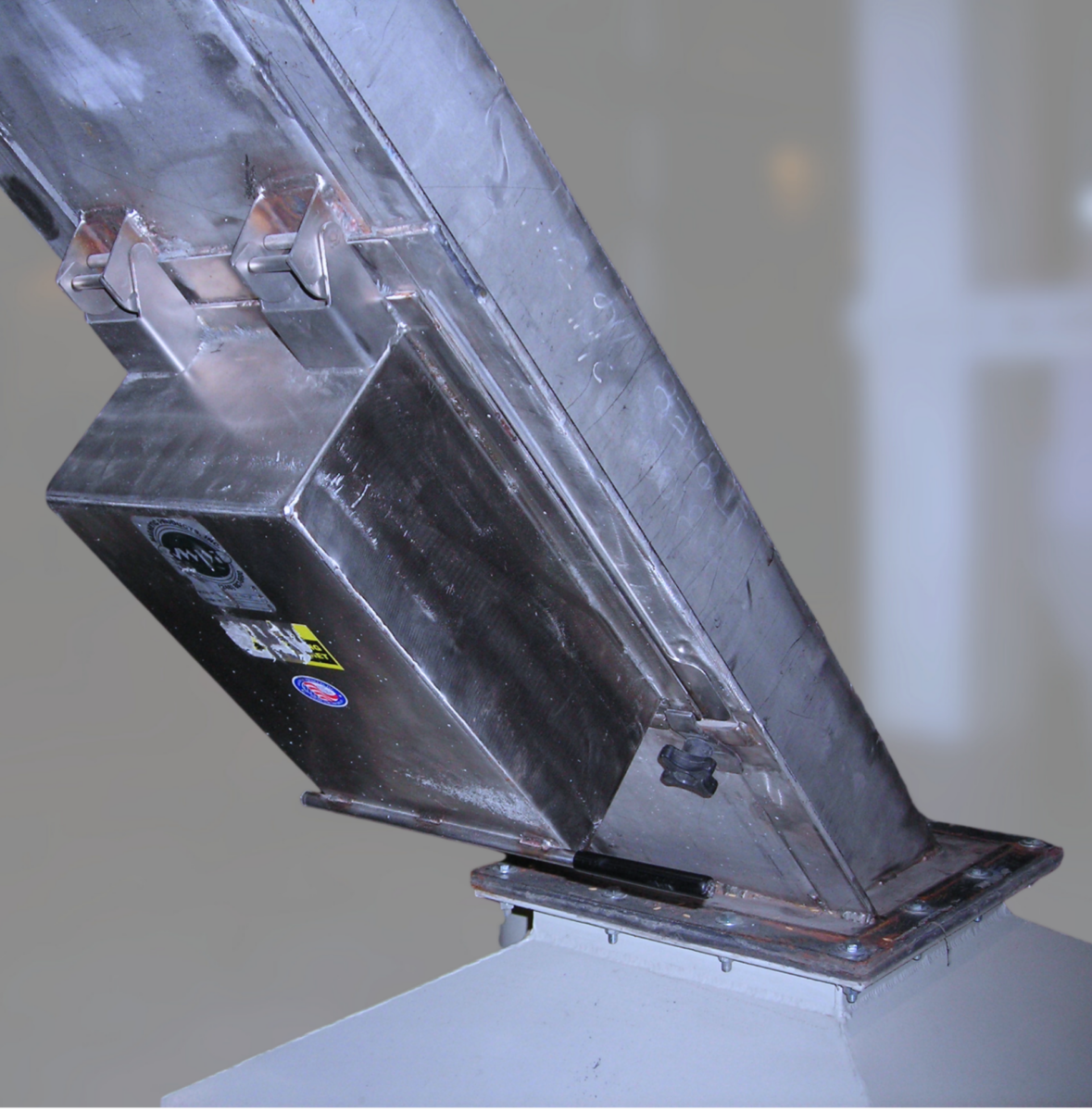

Plate Magnets are ideal for gravity-fed angled chutes with inclines of up to 60 degrees, effectively handling product streams ranging from low to high volumes. The product lineup includes Ceramic Plate Magnets, Hybrid Plate Magnets, and Rare Earth Plate Magnets. Each type is designed to perform efficiently within these angled chutes while accommodating varying product stream volumes.

Compatibility Check - What Type of Magnetic Separation Fits Your Application

MPI offers magnetic separation solutions tailored for bulk gravity applications, specifically designed to eliminate ferrous contaminants from free-flowing dry materials like powders, granules, and pellets. These high-performance magnets, including drawer, plate, and hump separators, are installed in chutes, hoppers, or silos and utilize advanced rare-earth magnet technology to achieve maximum capture efficiency. Options are available in manual, quick-clean, and self-clean configurations, built to endure demanding environments and high-volume throughput.

Ensure the protection of critical equipment, uphold product purity, and maintain regulatory compliance with MPI’s gravity-fed magnetic separators. These systems are built for durability and ease of maintenance, enhancing product quality and processing uptime across the food, plastics, minerals, and bulk solids sectors.