MPI’s Lift Magnets are powerful, compact tools designed for safely and efficiently lifting flat or round ferrous materials. Available in manual and battery-powered models, they eliminate the need for hooks, chains, or slings, reducing handling time and increasing operator safety in fabrication, warehousing, and machining environments. Improve material handling efficiency and minimize the risk with MPI Lift Magnets. Engineered for strength and reliability, these magnets streamline loading and unloading while protecting workers, making them ideal for fast-paced shops and metal-moving operations.

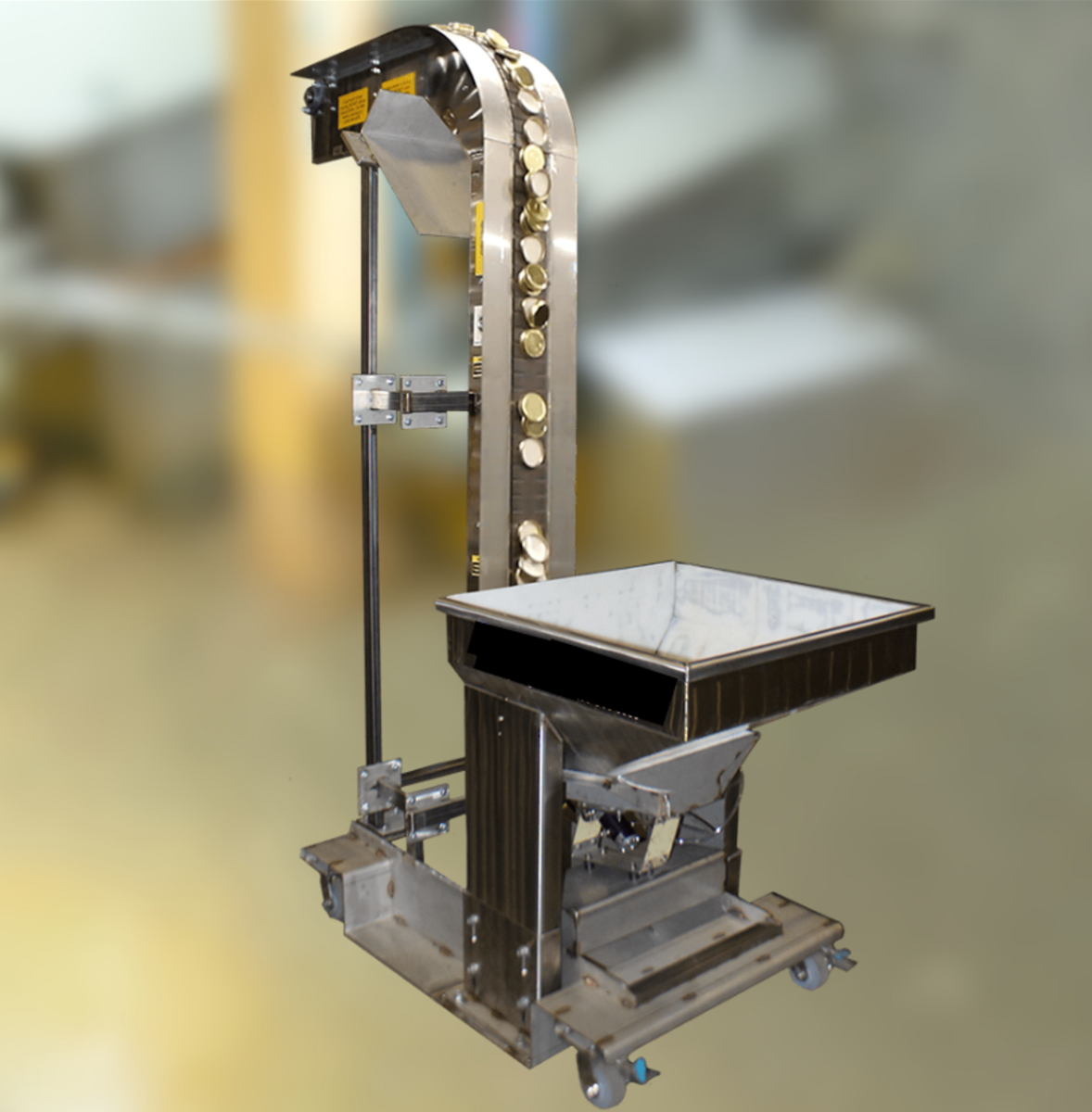

MPI's Magnetic Arm Tools are adjustable devices that hold, position, or retrieve ferrous parts during processes such as fabrication, welding, assembly, or inspection. They improve stability, control, precision, and operator safety while reducing strain and enhancing efficiency in manufacturing environments. Additionally, MPI's Magnetic Rails and Pulleys are used in conveyor systems to facilitate the movement of ferrous parts, helping with tasks like can handling and part positioning in automated setups. These solutions improve material flow, minimize jams, enhance alignment, and boost overall efficiency in manufacturing and packaging operations.

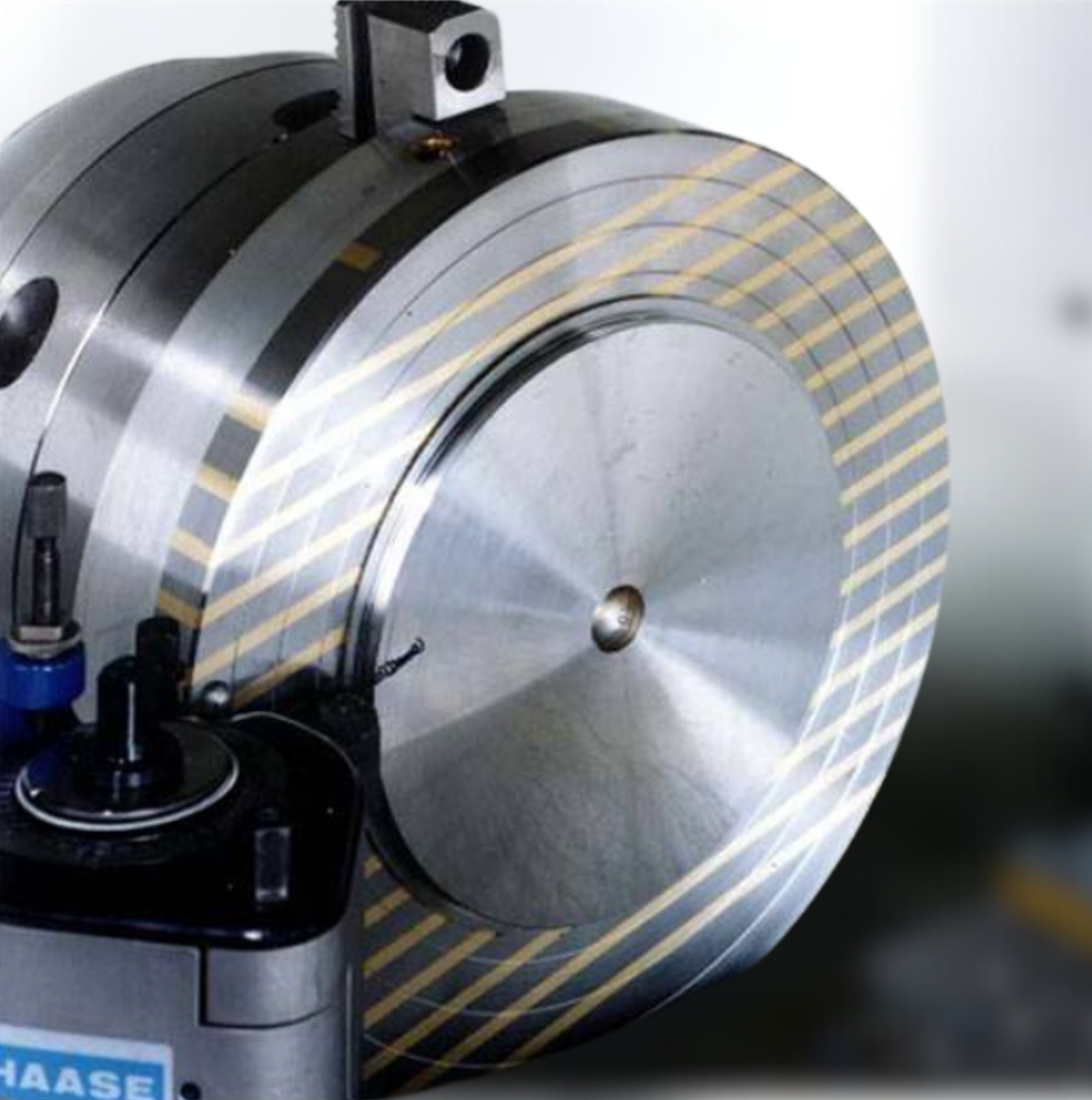

MPI Permanent Magnetic Chucks provide secure, consistent work holding for grinding, milling, or EDM operations. Their fail-safe design offers constant holding power without electricity and high magnetic stability across precision machine setups. Achieve unmatched holding security and repeatability with MPI Permanent Magnetic Chucks. Their simple, energy-free design increases productivity and reduces setup time, making them ideal for precision shops focused on safety, accuracy, and uptime.

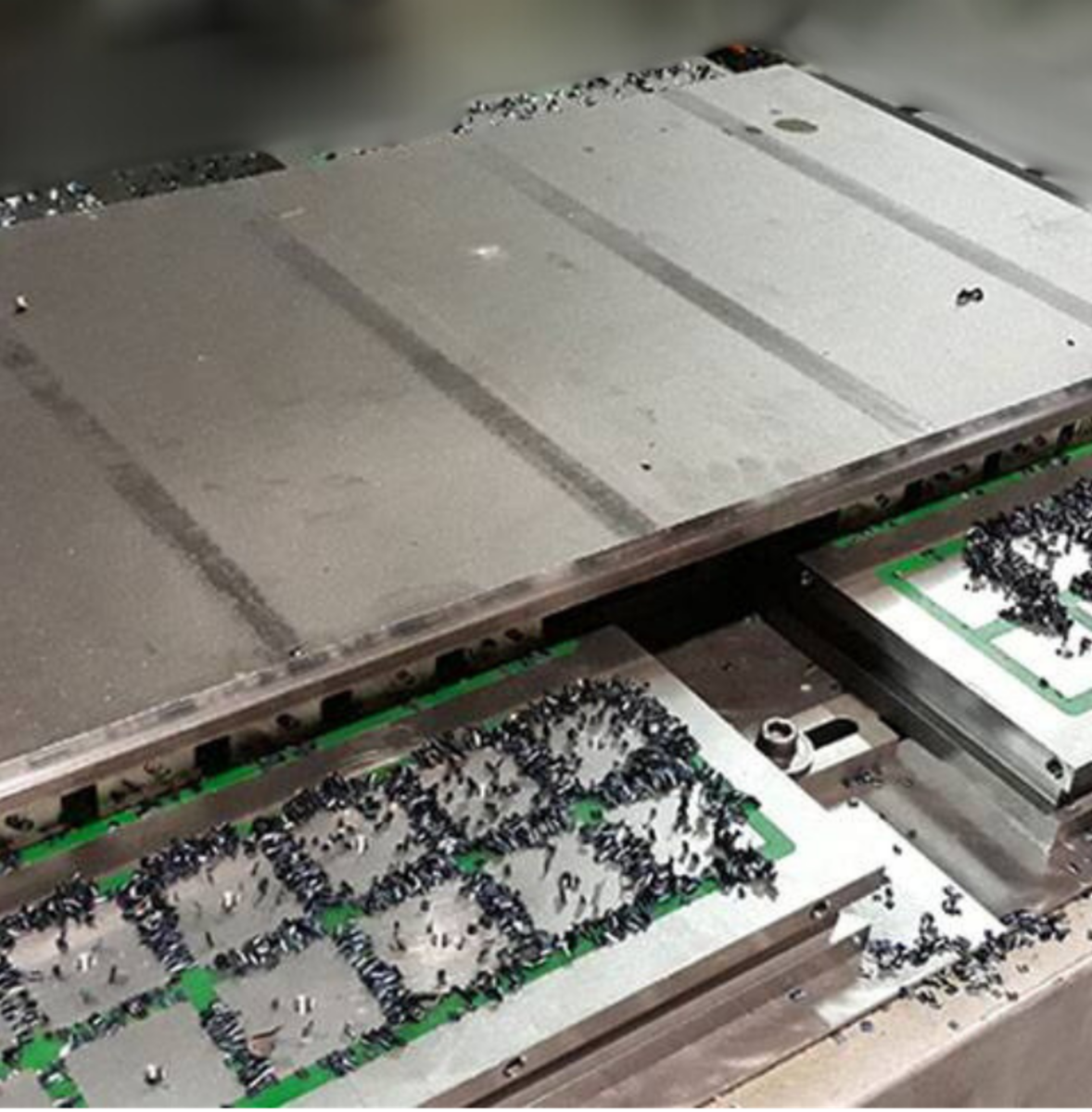

MPI’s Electro and ElectroPermanent Magnetic Chucks combine high holding power with push-button control, allowing fast work holding activation and release. Paired with intelligent controllers, these systems are suited for automated machining, CNC, and large workpiece applications. Unlock precision and flexibility with MPI’s programmable magnetic workholding. Electro and ElectroPermanent Chucks deliver consistent, high-strength clamping with easy integration into smart machine environments, reducing setup time, improving safety, and maximizing throughput.

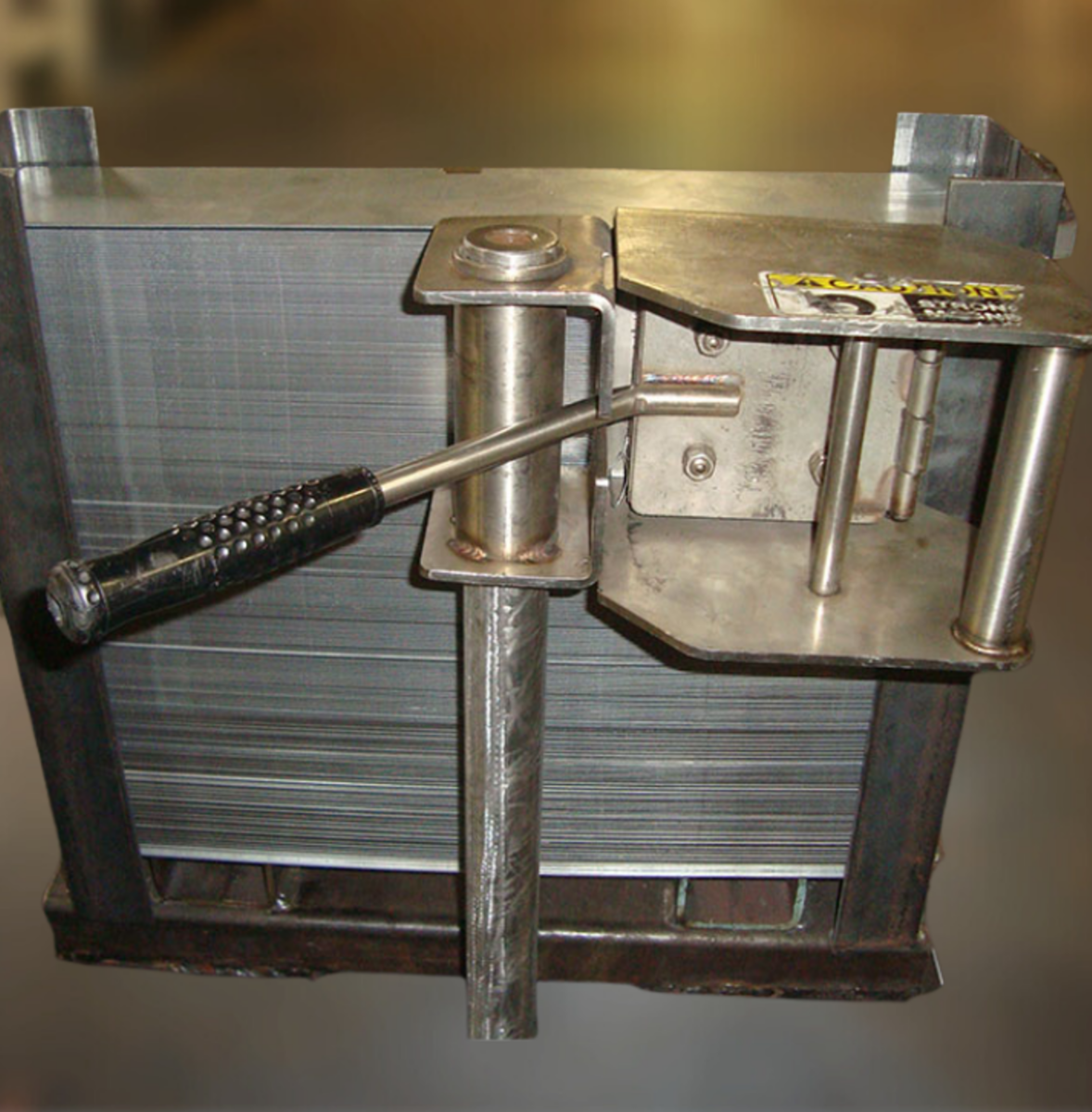

MPI Sheet Separators use powerful permanent magnets to fan out stacked steel sheets, preventing double-sheet feeding in stamping, forming, or laser-cutting lines. Available in fixed or adjustable configurations, they improve safety and speed up material handling. Simplify sheet handling with MPI’s reliable Sheet Separators. These maintenance-free tools enhance operator efficiency, reduce machine jams, and support high-speed automation, making them a must-have in any pressroom or sheet metal facility.

Compatibility Check - What Type of Magnetic Separation Fits Your Application

MPI's Automation and Workholding solutions are tailored to enhance efficiency, accuracy, and safety in metalworking and manufacturing settings. This product line features magnetic lifters, grippers, chucks, sheet separators, rails, and arm tools that facilitate part handling, optimize setup processes, and decrease cycle times. Whether for manual tasks or fully automated systems, MPI’s workholding tools deliver dependable performance across machining, stamping, assembly, and material transfer applications. Utilizing state-of-the-art permanent and electro-permanent magnetic technologies, these solutions boost productivity while reducing downtime, fixture complexity, and operator hazards—making them suitable for high-precision, high-speed, and heavy-duty tasks in various industries.