MPI offers several innovative solutions for improving efficiency and safety in manufacturing environments. The Pneumatic Automated Fanner Magnet automates sheet separation using compressed air and powerful magnets, making it ideal for robotic press lines and high-speed stamping by minimizing labor and enhancing feed reliability. The MPI Stack Tracker monitors sheet stack levels and alerts operators when replenishment is needed, improving material flow visibility and reducing downtime in automated feeding systems. Meanwhile, MPI's Sheet Separators utilize robust permanent magnets to ensure consistent single-sheet feeding in stamping and laser-cutting applications, preventing jams and enhancing safety while being maintenance-free and energy-efficient. These solutions collectively enhance throughput, support lean manufacturing, and protect tooling in high-paced production settings, particularly in metal fabrication and automotive industries.

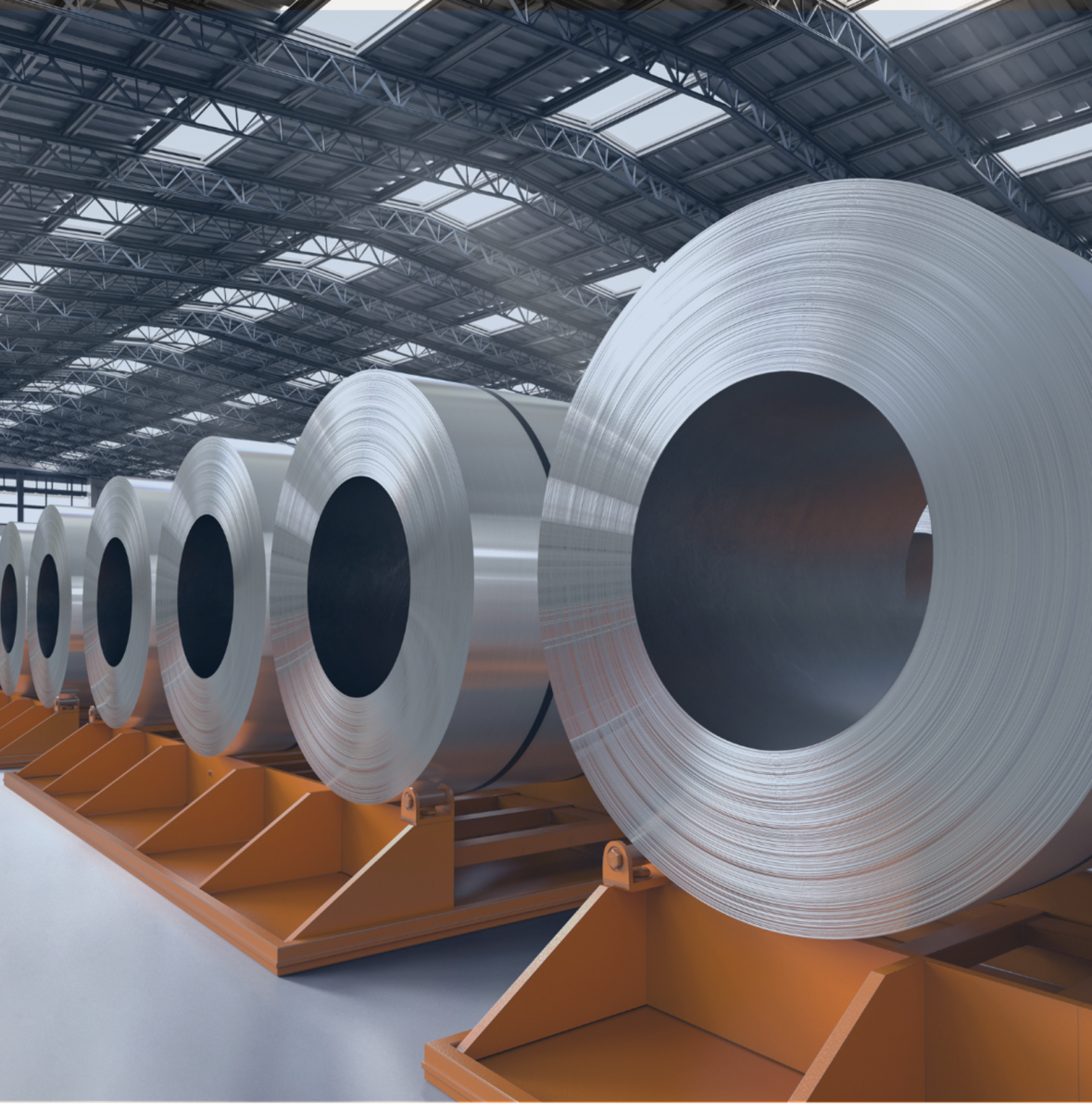

MPI’s Sheet Separators use powerful permanent magnets to fan out stacked steel sheets, ensuring consistent single-sheet feeding in stamping and laser-cutting applications. Designed for fast-paced pressrooms, they eliminate double-sheet errors, reduce jams, and improve safety. With no power required, they’re a maintenance-free solution that boosts efficiency and protects tooling—ideal for metal fabrication, automotive, and appliance production environments.

The MPI Stack Tracker enhances material flow visibility by monitoring and signaling when sheet stacks reach pre-set levels. Ideal for automated feeding systems, it reduces operator guesswork, minimizes downtime, and ensures seamless sheet replenishment. By providing accurate stack-height monitoring, the Stack Tracker improves throughput, supports lean manufacturing, and prevents production delays in high-volume metal stamping and forming operations.

MPI’s Pneumatic Automated Fanner Magnet brings hands-free automation to sheet separation. Using compressed air, the unit positions and actuates powerful magnets to fan out steel sheets precisely when needed. Perfect for robotic press lines and high-speed stamping, it reduces labor, improves feed reliability, and integrates easily into automated workflows—enhancing safety, speed, and part handling consistency in modern manufacturing lines.

Sheet Separator Comparison

Unique Benefits and Considerations

| Chute Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| Sheet Separator | Maintenance-free permanent magnet design. No power required for operation. Eliminates double sheet errors and increases press uptime. | Manual setup and adjustment required. Not ideal for automated lines. |

| Stack Tracker | Monitors sheet stack levels in real time. Reduces operator guesswork and prevents production interruptions. Compact, easy to install. | Does not separate sheets. Requires integration with control systems for alerts. |

| Pneumatic Automated Fanner Magnet | Fully automated sheet separation using compressed air. Ideal for robotic or high-speed press lines. Enhances feed reliability and safety. | Requires air supply and integration. Higher initial cost and setup complexity. |

Industries, Applications and Regulations

For assistance in selecting the most suitable sheet separator for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!