MPI’s magnetic pull test kit offers the most accurate and user-friendly solution for measuring the strength of magnets. This compact, battery-operated gauge (four AA batteries included) is designed to fit in tight spaces. With a capacity of 44 lbs (20 kg), the kit can measure pull in various units including pounds, ounces, kilograms, newtons, or kilonewtons, and it retains the last reading after release. Housed in a durable, foam-padded carrying case, this compact unit comes with all necessary accessories and can accommodate a wide range of magnet types and configurations. The documentation generated from these tests is suitable for compliance with Hazard Analysis and Critical Control Point (HACCP) plans or for meeting documentation requirements under the Food Safety Modernization Act (FSMA).

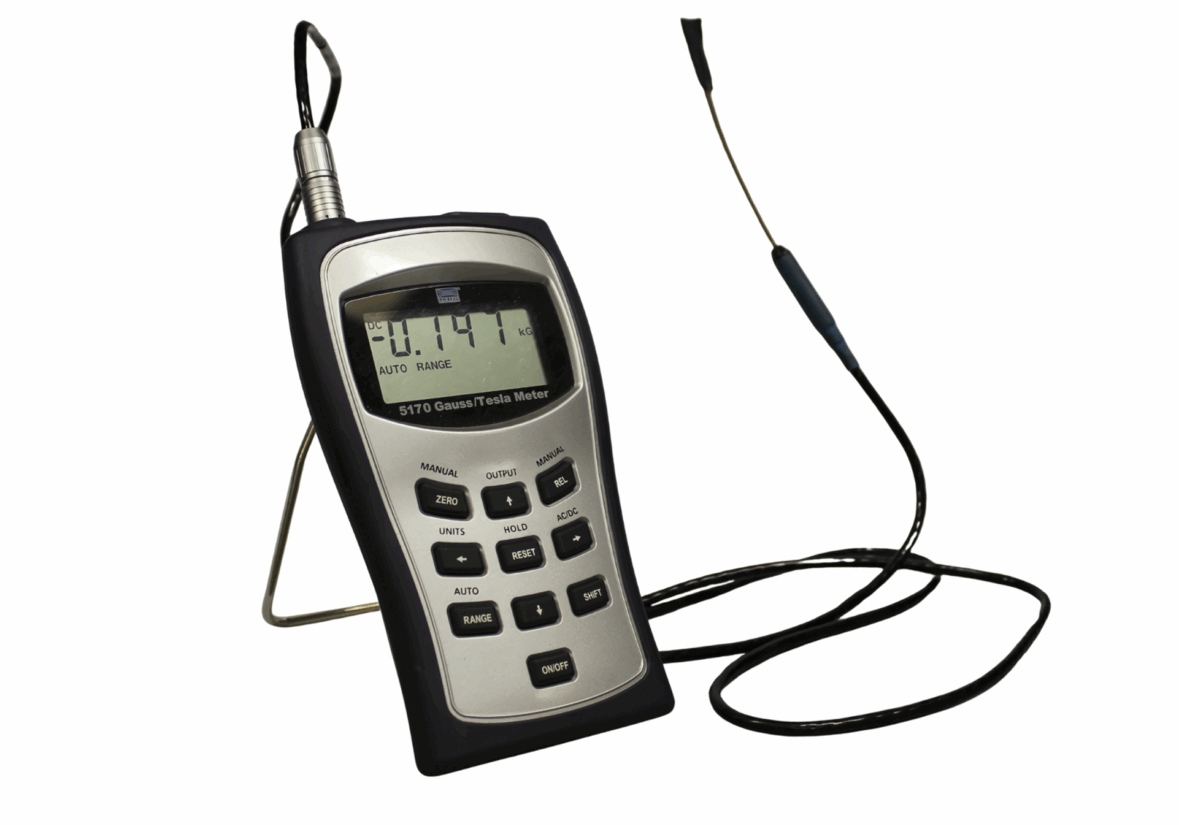

MPI’s Gauss Meter is a precise, handheld instrument that measures the surface magnetic field strength of permanent magnets, magnetic separators, and equipment components. Ideal for quality assurance, maintenance, and R&D teams, the meter enables non-invasive, real-time detection of magnetic field intensity in gauss or tesla units. Designed to work with a range of probe types, including axial and transverse, MPI’s Gauss Meter helps verify magnet performance, identify degradation, and support documentation for regulatory compliance. Whether auditing incoming magnetic devices or maintaining magnetic strength in critical process lines, this tool provides the insight to ensure system integrity and process safety.

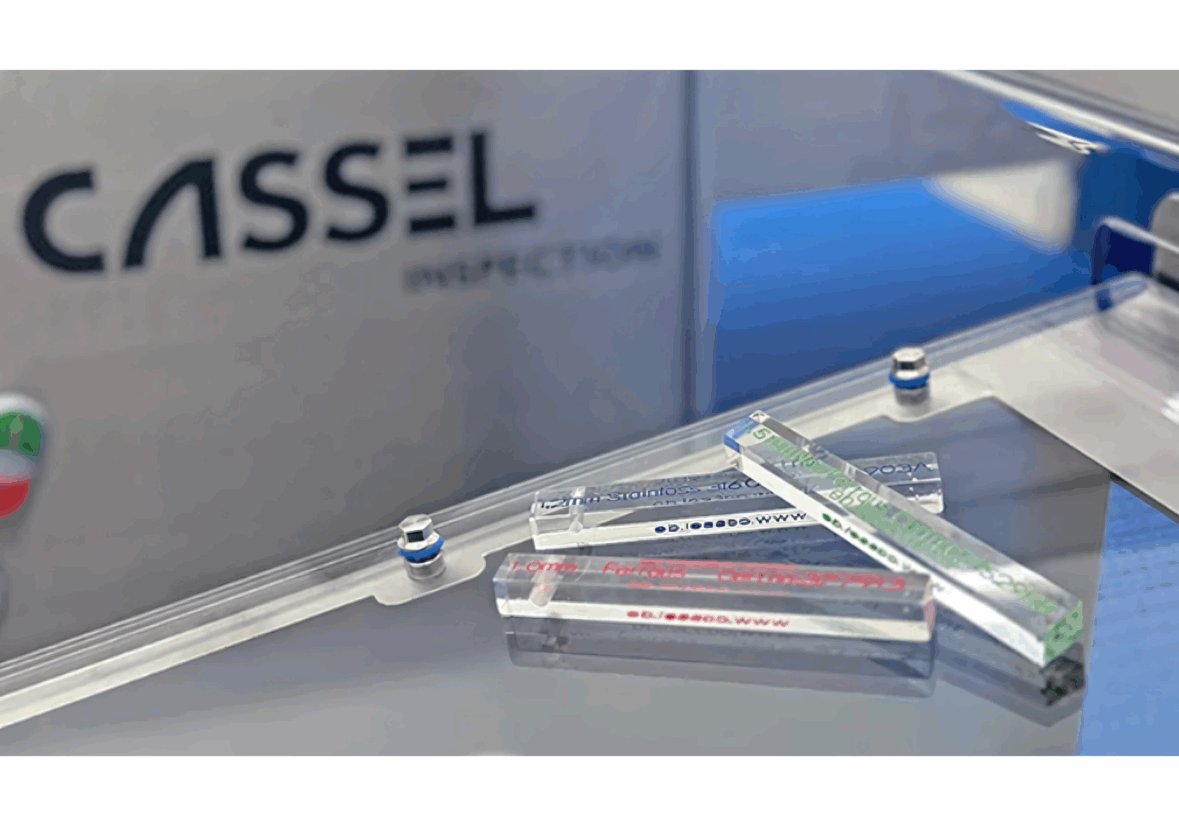

MPI’s Metal Detector Test Sticks are high-precision calibration tools designed to verify the performance of metal detection systems across food, pharmaceutical, plastics, and general manufacturing lines. Each stick encases a certified, contaminant-sized metal sphere—ferrous, non-ferrous, or stainless steel—within a durable, food-grade plastic housing, ensuring consistent test results without product contamination. Available in various sizes and colors for easy identification, MPI test sticks are essential for routine validation, compliance with HACCP and GFSI protocols, and internal quality assurance programs. Use them to confirm sensitivity, detectability, and reject functionality of tunnel, gravity, and pipeline metal detectors.