MPI’s Mounted and Suspended Sorting Systems are designed to safeguard processing equipment, enhance product purity, and optimize operational efficiency by eliminating unwanted tramp metal from conveyed product streams. Suitable for both high-speed conveyors and deep burden depths, MPI offers electromagnet and permanent magnet options, available in Quick-Clean or Self-Clean configurations to meet your specific maintenance and throughput requirements. These systems are ideal for various industries, including recycling, aggregates, food processing, and mining, where metal contamination can pose substantial safety and quality concerns. With models tailored for both dry and wet applications, MPI’s magnetic separators ensure robust performance, reduced downtime, and adaptable installation options.

Mounted and Suspended Sorting Systems also shield downstream equipment from damage, diminish the risk of fire and explosion associated with spark-generating tramp metal, improve product quality by removing contaminants, and boost system efficiency with minimal manual intervention. They are available in both manual and automated cleaning options, allowing for customized maintenance control. Supported by MPI’s expertise in magnetic separation, these systems deliver dependable, low-maintenance solutions tailored for challenging industrial environments.

Offering high-intensity magnetic separation without electrical power, this permanent magnet is ideal for applications with belt speeds up to 250 FPM. Its large magnetic face allows significant tramp metal accumulation before cleaning, and its quick-clean feature minimizes maintenance time in low-to-moderate volume applications.

Designed for continuous operation on fast conveyor belts, this self-cleaning system provides consistent tramp metal removal without requiring power. Its space-saving profile fits tight installations, while the automatic discharge belt ensures uninterrupted processing of large or small material volumes, wet or dry.

Engineered for demanding material handling environments, this oil-cooled electromagnet effectively captures both large and small tramp metal from conveyed products with heavy burden depths. The quick-clean design simplifies maintenance while ensuring consistent performance, making it ideal for moderate-speed belt or vibratory conveyors up to 250 FPM.

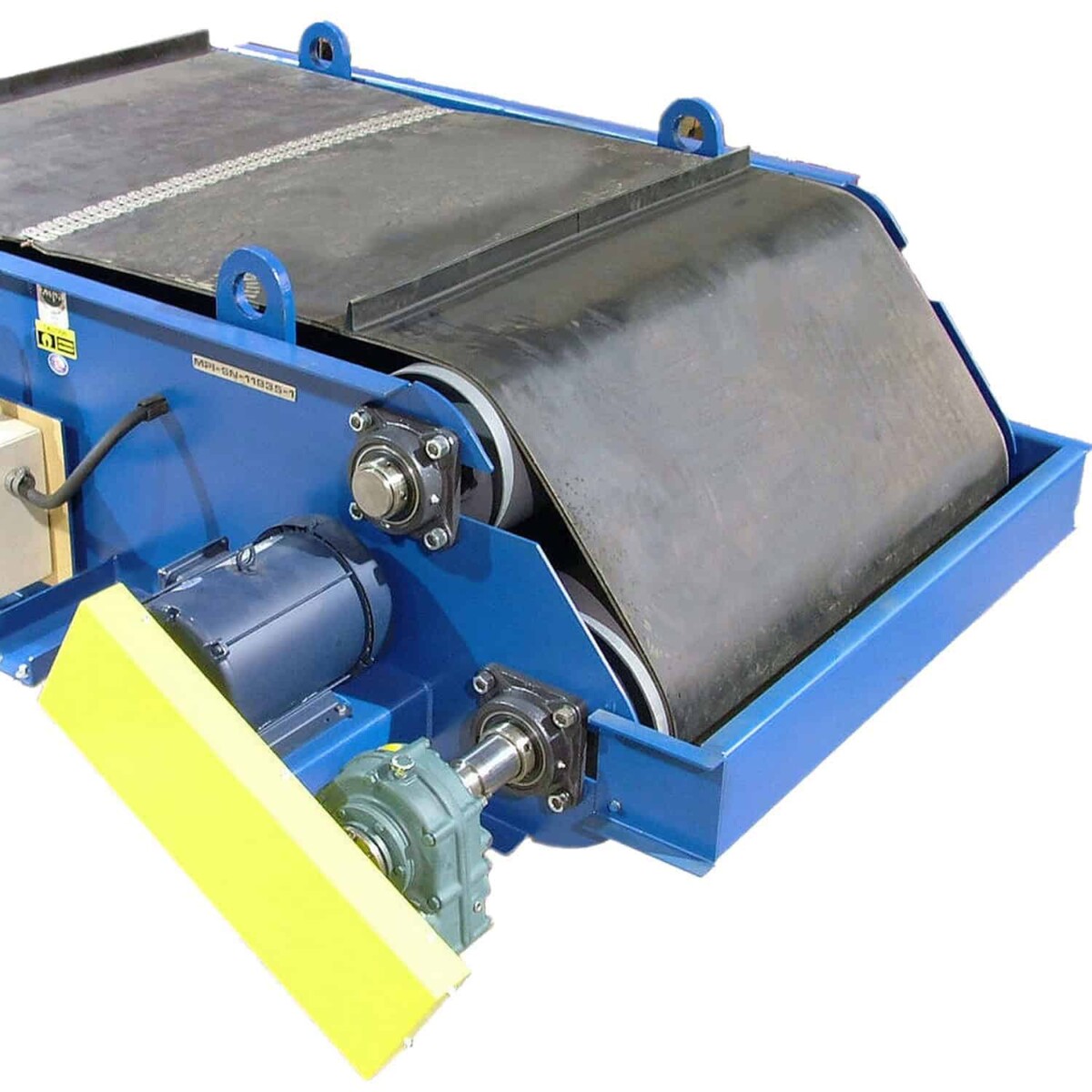

This robust system combines oil-cooled electromagnet power with an integrated self-cleaning belt to automatically discharge captured tramp metal. It’s built to handle fast-moving conveyor belts and high product volumes, reducing manual intervention while maximizing operational uptime.

Compatibility Check - Mounted & Suspended Sorting Magnetic Separator Comparison

Unique Benefits and Considerations

| Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| Quick-Clean Suspended Permanent Magnet | Permanent magnet with large face area. Manual quick-clean design. Captures small to large tramp metal. Works at speeds up to 250 FPM. Suspension heights up to 10” with bucking option. No power required. Lower operational cost. High tramp metal holding capacity. | The quick-clean feature requires some downtime. |

| Self-Clean Suspended Permanent Magnet | Permanent magnet with self-cleaning belt. Effective for both fine/coarse, wet/dry materials. Space-saving low-profile design. Handles high-speed belts and large volumes. Suspension heights up to 10” with bucking option. Fully automatic cleaning. No power required. Space-efficient. | Higher initial cost. |

| Quick-Clean Suspended Electromagnet | Oil-cooled electromagnet with quick-clean design. Removes medium to large tramp metal. Ideal for belt or vibratory conveyors operating at up to 250 FPM. Suitable for heavy burden depths. Strong magnetic pull, simple design, and no moving parts on the discharge system. | Quick-clean feature requires some downtime. |

| Self-Clean Suspended Electromagnet | Oil-cooled electromagnet with integrated self-cleaning discharge belt. Designed for high-speed conveyor belts. Handles large burden depths. Continuous operation reduces manual labor, making it ideal for high-throughput systems. | Requires electrical power and is a more complex system than other MPI models. |

Industries, Applications and Regulations

For assistance in selecting the most suitable mounted and suspended sorting systems for your application or to explore additional customization options, contact Magnetic Products Inc. today to speak with our team of experts.