Available in Drawer Style or Hinge Mount Configurations

MPI Quick-Clean Chute Magnets are engineered for high-volume, gravity-fed material flows, ensuring the effective removal of medium to large ferrous contaminants. Unlike conventional magnetic grates that may lead to clogging or bridging in heavy product flows, these chute magnets ensure smooth operation while enhancing product quality and safeguarding downstream equipment such as milling, processing, and packaging systems.

Suitable for sectors such as food processing, plastics, pharmaceuticals, recycling, feed production, chemical processing, and grain handling, these chute magnets offer a dependable solution for contamination management and equipment safety. Their powerful rare-earth magnetic fields efficiently capture and retain tramp metal, minimizing the risk of damage to essential machinery.

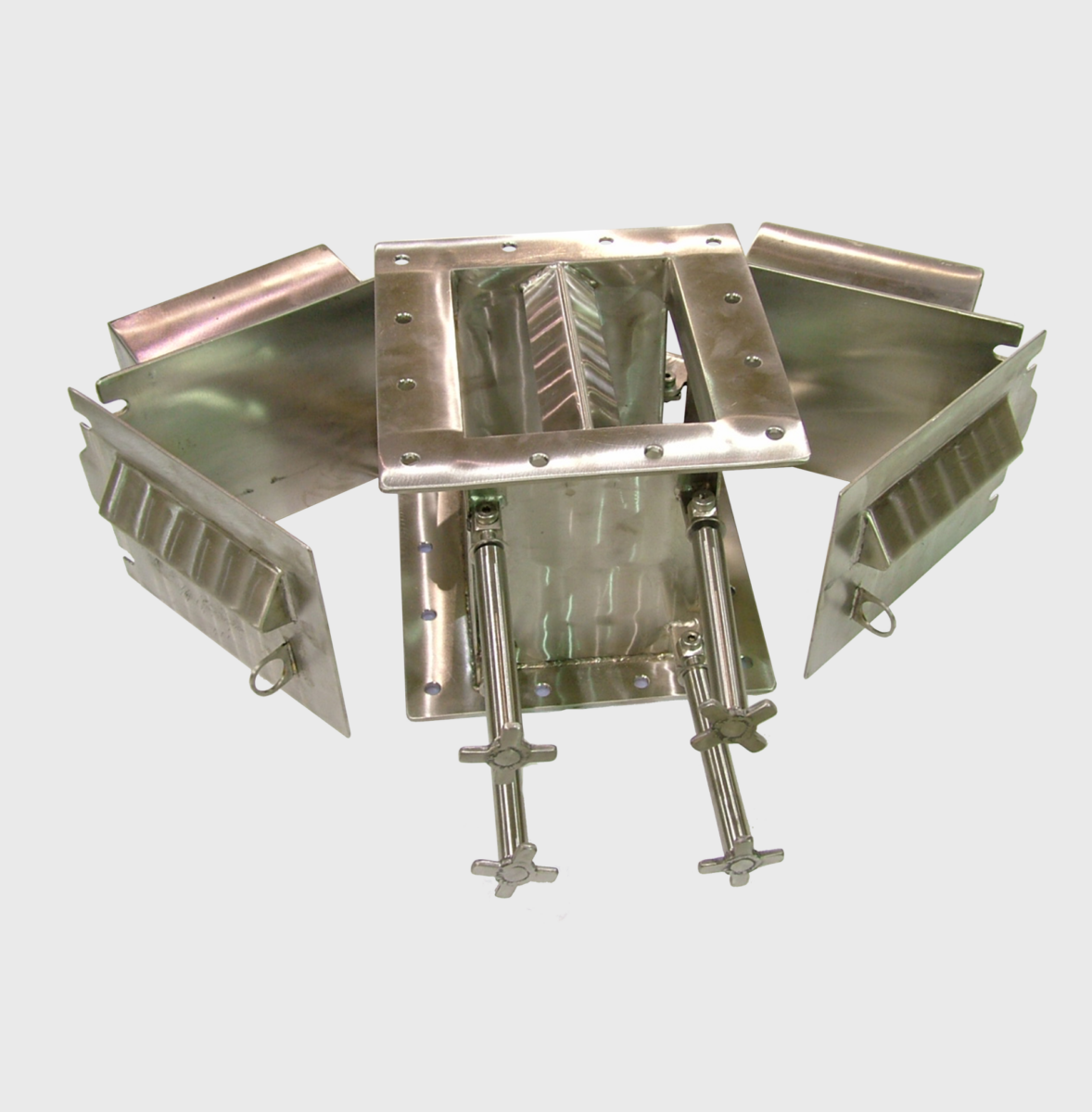

The Quick-Clean mechanism facilitates maintenance and rapid, tool-free cleaning with a pull-out drawer magnet. Operators can quickly pull out the magnet drawer, eliminate contaminants, and reset the system in seconds, reducing downtime and boosting productivity. This efficient design makes MPI Quick-Clean Chute Magnets reliable high-performance magnetic separation and a cost-effective option for businesses that require high performance and straightforward maintenance in vertical or near-vertical chute applications.

Benefits of the Quick-Clean Chute Magnet From Magnetic Products, Inc

-

Quick-Clean Mechanism

Innovative design enables fast and easy cleaning, reducing downtime and labor requirements.

-

High-Intensity Magnetic Circuit

Utilizes powerful rare-earth magnets to capture fine and coarse ferrous contaminants.

-

Rugged Construction

Built with heavy-duty stainless steel to ensure long-term durability and resistance to wear and corrosion.

-

Magnetic Material Options

Rare-earth neodymium or ceramic (depending on application).

-

Compact Footprint

- Designed to integrate seamlessly into existing systems without significant modifications.

-

Food-Grade Options

FDA-compliant materials and coatings available for food and pharmaceutical applications.

-

Customizable Configurations

Tailored designs to meet specific system and contamination control requirements.

-

Variety of Chute Sizes

Standard sizes range from 4 inches to 24 inches, with custom sizes available upon request.

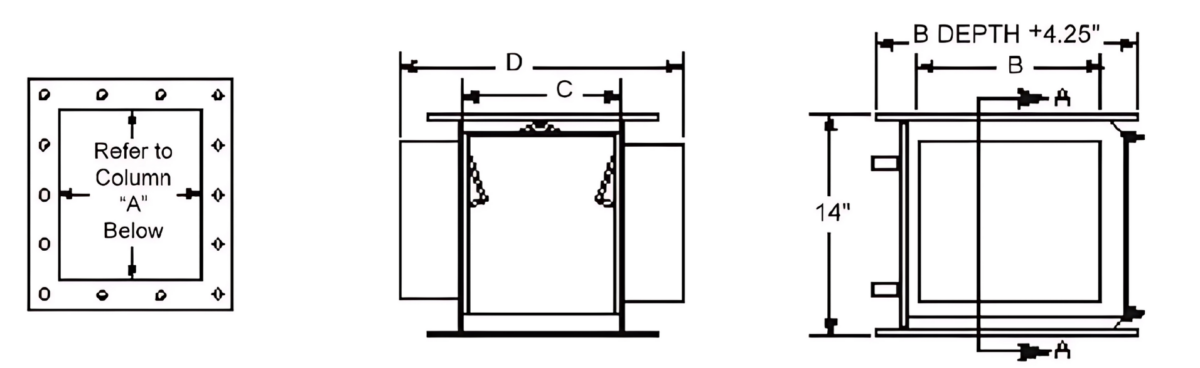

Quick-Clean Chute Magnet Product Details

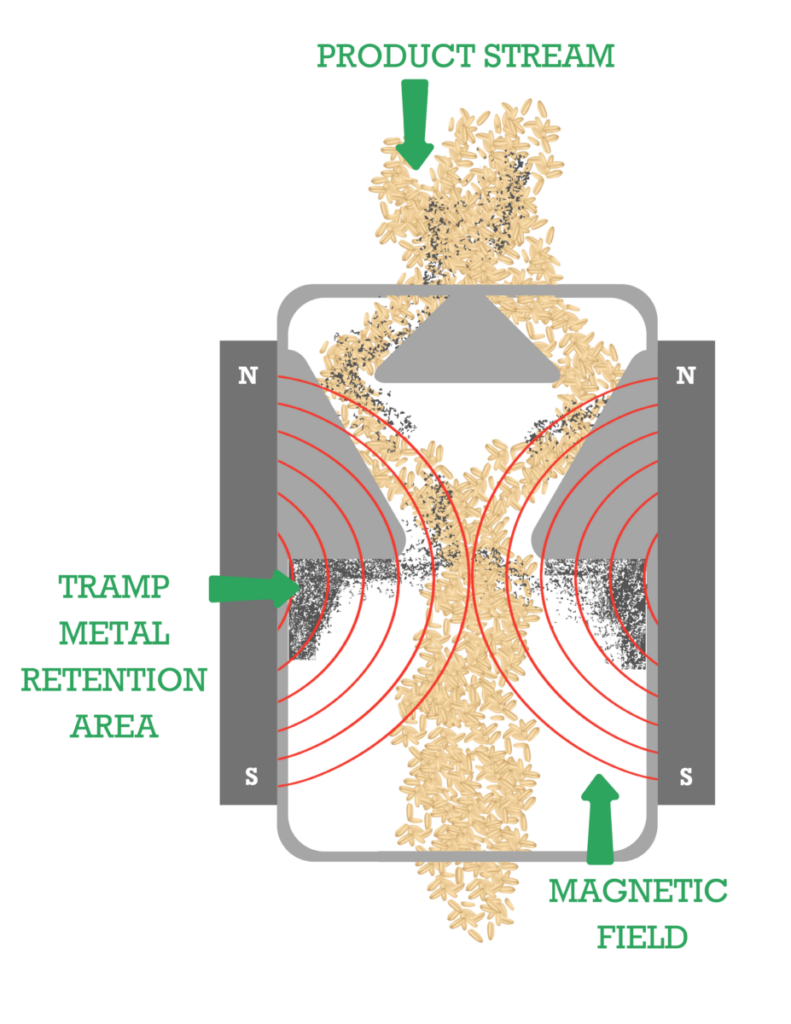

MPI Quick-Clean Chute Magnets are installed within a chute or vertical material flow system. As material flows through the chute, the magnetic field generated by the powerful rare-earth magnets attracts and retains ferrous contaminants.

The product stream flows between two large permanent plate magnets located on either side of the chute. A center diverter directs the product flow towards the working surface of the two plate magnets, which are stepped to minimize tramp metal “wash-off.”

Tramp metal contaminants are captured from the product stream and collected under the step of the plate magnet. The cleaning shell or operator safely removes the tramp metal from the product stream to a disposal area outside the chute. Tramp metal contaminants are captured out of the product stream as it flows through the chute. The quick-clean mechanism allows operators to easily remove the captured contaminants without extensive downtime.

Operators simply pull the magnet drawer or assembly out, dislodge the contaminants, and reset the magnet for continued operation, ensuring uninterrupted performance.

Quick-Clean Mechanism

The Quick-Clean feature allows operators to efficiently remove collected tramp metal with minimal effort and downtime. The cleaning process follows these steps:

- Pausing the Product Flow – The process stream is briefly halted to enable safe cleaning.

- Opening the Quick-Clean Drawer Assembly – Operators pull the magnet drawer or assembly outward, exposing the captured contaminants.

- Dislodging and Disposing of Metal Debris – The trapped ferrous material is safely removed and discarded in a designated disposal area outside the chute.

- Resetting for Operation – The magnet assembly is pushed back into place, restoring full operation.

By streamlining the cleaning process, the MPI Quick-Clean Chute Magnet minimizes production interruptions while ensuring consistent magnetic separation performance. This results in improved product purity, enhanced equipment protection, and greater operational efficiency.

Quick-Clean Chute Magnet Specification Table

US Customary Units

| QUICK CLEAN CHUTE MODEL # | (B) FLOW OPENING WIDTH (IN.) | (C) FLOW OPENING DEPTH (IN.) | OVERALL LENGTH (IN.) | APPROX. WEIGHT (LBS.) | FLOW RATE (FT3/HR) |

|---|---|---|---|---|---|

| MC-808-QC | 8 | 8 | 12.25 | 154 | 1,200 |

| MC-810-QC | 10 | 8 | 14.25 | 192 | 1,500 |

| MC-812-QC | 12 | 8 | 16.25 | 231 | 2,000 |

| MC-1010-QC | 10 | 10 | 14.25 | 195 | 2,200 |

| MC-1012-QC | 12 | 10 | 16.25 | 233 | 2,500 |

| MC-1014-QC | 14 | 10 | 18.25 | 272 | 3,000 |

| MC-1016-QC | 16 | 10 | 20.25 | 311 | 3,500 |

| MC-1018-QC | 18 | 10 | 22.25 | 350 | 4,000 |

| MC-1020-QC | 20 | 10 | 24.25 | 389 | 5,000 |

| MC-1022-QC | 22 | 10 | 26.25 | 428 | 6,000 |

| MC-1024-QC | 24 | 10 | 28.25 | 467 | 7,000 |

| MC-1026-QC | 26 | 10 | 30.25 | 506 | 8,500 |

| MC-1028-QC | 28 | 10 | 32.25 | 545 | 10,000 |

Quick-Clean Chute Magnet Customizations and Variations

Quick-Clean Chute Magnet for Off-Loading Animal Feed Grain

Quick-Clean Magnetic Chute Installed for Processing Powdered Milk

Quick-Clean Chute Magnetic Separator

Quick-Clean Chute Magnetic Separator