Self-Purging High-Intensity Magnetic Filter

The patented AutoMag® unit represents the latest generation of self-cleaning, high-intensity magnetic filters designed for high-flow and highly contaminated industrial applications. The AutoMag® features two flow chambers. Fluid first enters the inlet chamber, where primary filtration occurs. The partially filtered fluid then moves to a second chamber, where its flow is slowed for final filtration treatment before returning to the process. The installation of AutoMag® enhances manufacturing efficiency and minimizes operator intervention.

AutoMag® is an automated, self-cleaning magnetic filtration system that provides continuous, operator-free magnetic filtration with exceptional removal capacity. The AutoMag® system from Eclipse utilizes powerful 'Rare Earth' magnetic materials to enhance the quality, efficiency, and performance of manufacturing, grinding, and finishing processes.

This system requires only a minimal amount of compressed air to operate cartridge and bag filters that typically use consumables. Completely autonomous, the AutoMag® does not necessitate operator involvement. These advantages guarantee a payback period that can be measured in months rather than years.

In addition, AutoMag® delivers significant benefits across various manufacturing applications, ranging from industrial part washing systems to vehicle pre-paint body washing stations and any other processes that depend on a clean supply of filtered fluid.

Benefits of the AutoMag® From Magnetic Products, Inc

-

Automated Self-Cleaning Technology

The AutoMag® system features a fully automatic self-cleaning mechanism that continuously removes ferrous contaminants. This automation reduces the need for manual intervention, minimizing maintenance downtime and labor costs.

-

Superior Filtration Performance

Unlike conventional filters that rely on mesh size, AutoMag® captures ferrous and paramagnetic particles of all sizes, including sub-micron contaminants. It prevents the recirculation of harmful metal debris that can cause pump, gear, slideway, and valve wear.

-

Versatile Fluid Compatibility

Designed for use with various fluids, including oil, coolant, and water. It can be installed in pre- or post-fluid holding tanks, at machine inlets, or within process lines for flexible integration.

-

Improved Process Efficiency and Surface Quality

Fully filtered fluids enhance machining precision, improving surface finishes, dimensional accuracy, and overall product quality. Particularly beneficial for applications requiring fine finishing, grinding, honing, and milling.

-

Extended Equipment and Tool Life

Ensures a contaminant-free fluid supply, AutoMag® reduces abrasive wear on machine components. Extends the operational life of grinding wheels, cutting tools, and pumps, reducing replacement costs.

-

High-Capacity Magnetic Filtration

Features a double magnetic length design, ensuring a larger contamination collection capacity. Uses high-intensity rare-earth magnets to extract even the finest metal particles efficiently.

-

Environmentally Friendly & Cost-Effective

Eliminates the need for disposable filter consumables, reducing waste and environmental impact. Cuts costs on fluid disposal and filter replacement, offering long-term operational savings.

-

Compact & Low-Maintenance Design

The system is compact and easy to install, fitting into existing fluid handling setups with minimal space requirements. Fully self-purging, meaning contaminants are automatically discharged without requiring system shutdowns.

AutoMag® Product Details

The AutoMag® Magnetic Filtration System operates using advanced high-intensity magnetic technology to continuously remove ferrous and paramagnetic contaminants from industrial fluids. Unlike conventional filtration methods, AutoMag® is not particle-size sensitive—if a particle is magnetic, it will be captured, even at sub-micron levels.

Contaminant Capture and Filtration Process

- Contaminated fluid enters the AutoMag® filtration chamber, where high-intensity rare-earth magnetic cores attract and capture ferrous particles.

- The system’s Dual Flow Technology™ ensures that fluid is exposed to the magnetic field for maximum duration, allowing for nearly 100% contaminant removal on the first pass.

- As the fluid flows through, metallic contaminants adhere to the magnetic core surfaces, preventing them from recirculating and causing wear to equipment.

- Once filtered, clean fluid is returned to the process line, ensuring improved fluid quality and system performance.

Automated Self-Cleaning Process

AutoMag® features a fully automated self-cleaning cycle, minimizing maintenance and eliminating the need for manual intervention. The cleaning process works as follows:

- Cleaning Activation:

-

- A signal from the user’s control system triggers the cleaning cycle.

- The outlet valve (not included but required) redirects fluid to a purge tank or a reclamation unit (available as an option).

- Magnetic Core Retraction & Purging:

-

- A centrally positioned pneumatic cylinder withdraws the magnetic elements from the filter, separating the captured ferrous debris from the magnetic cores.

- Simultaneously, the purge valve opens, allowing contaminants to be flushed away.

- Contaminant Removal:

- As the compressed air lifts the cores, ferrous contaminants are released from the tubes and washed away for collection in the purge tank or disposal unit.

- This ensures zero contamination build-up, maintaining consistent filtration efficiency.

- System Reset & Continuous Operation:

- Once cleaning is complete (typically in 10-15 seconds, depending on fluid type and filter location), the magnetic elements are reinserted, and the outlet valve returns to its original position.

- The AutoMag® system automatically resumes operation, ensuring continuous filtration without process interruption.

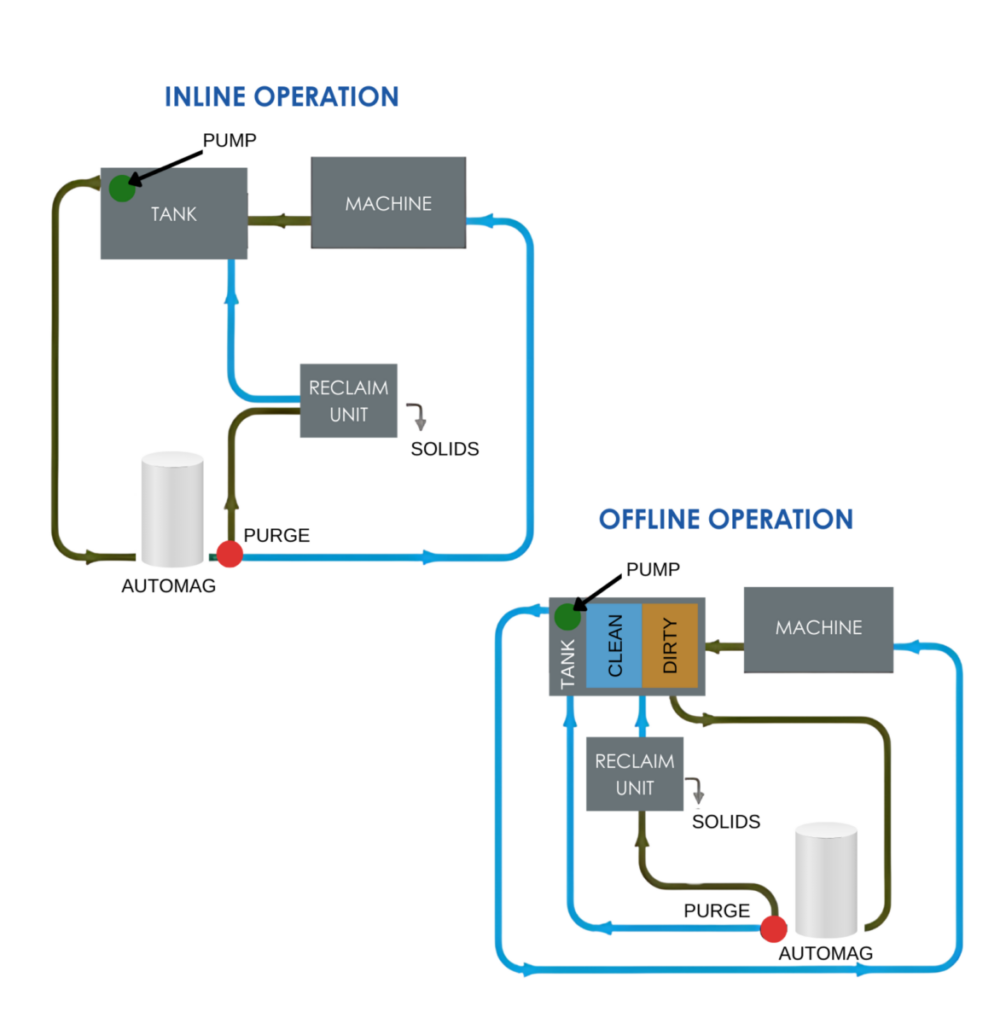

Installation Flexibility

- Inline / In-Process Installation: AutoMag® can be installed directly within fluid circulation systems, providing continuous filtration as fluids are used in production processes.

- Offline / Off-Process Installation: The system can also be set up separately, filtering fluids in a dedicated filtration loop, ensuring that fluid reservoirs remain free of contaminants before being recirculated.

By leveraging automated magnetic filtration, AutoMag® reduces pump wear, extends tool life, improves fluid clarity, and enhances process efficiency, making it an ideal solution for metalworking, manufacturing, food production, and more.

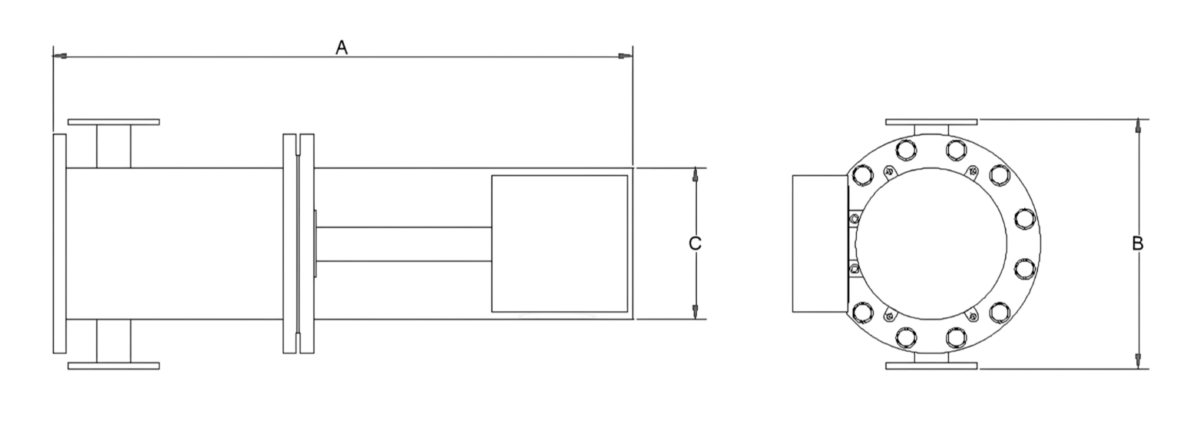

AutoMag® Specification Table

US Customary Units

| AUTOMAG MODEL # | (A) TUBE HEIGHT (IN.) | OVERALL HEIGHT (IN.) | (B) OPENING WIDTH (IN.) | (C) FLOW OPENING WIDTH (IN.) | FLOW RATE (GAL./MIN.) | CAPACITY (LBS.) | CONNECTION FLANGE (IN.) |

|---|---|---|---|---|---|---|---|

| AMC | 29 | 28.7 | 11.8 | 7.9 | 52 | 5 | 1.5 |

| AMC-6 | 42 | 42 | 17.7 | 10.8 | 119 | 15 | 2 |

| AMC-12 | 45 | 45 | 15.9 | 238 | 30 | 3 | 45 |

AutoMag® Installations & Variations

AutoMag® Models for a Variety of Industrial Fluid Processing

AutoMag® Installed for High-Flow Rate Oil Processing

AutoMag® for Integration into Existing Processing Line for Continuous Filtration in Large-Volume Fluid Applications