Compact, In-Line Magnetic Protection for Pneumatic Conveying Systems

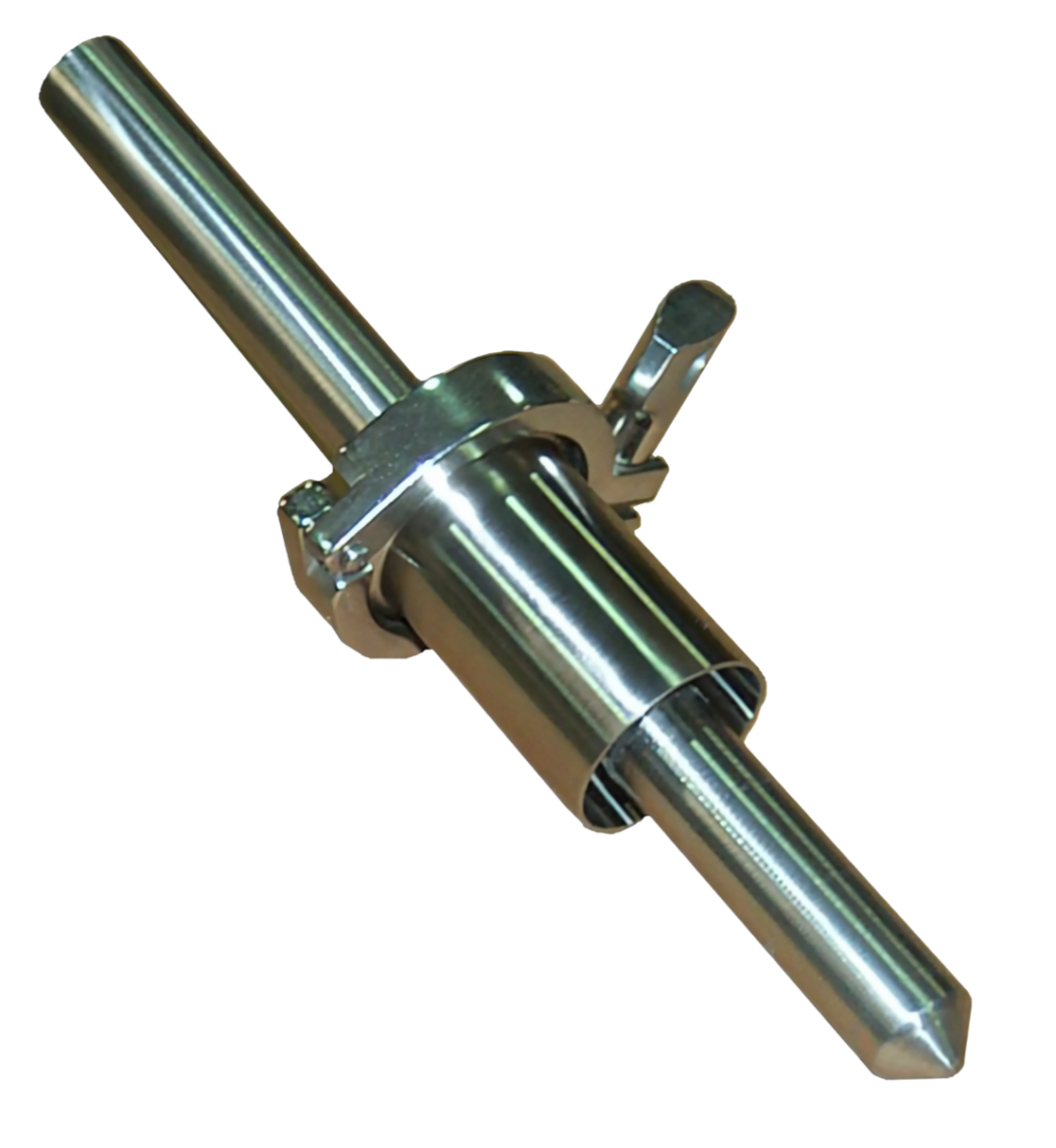

The MPI Pneumatic Tube Magnet is a compact, cost-effective solution for removing ferrous contaminants from materials conveyed through pressurized pneumatic lines. Designed to protect sensitive downstream equipment such as extruders, mills, and packaging machines, this magnet features a powerful rare-earth magnetic cartridge housed within a sanitary, stainless steel tube body.

Installed in-line with vertical or horizontal pneumatic pipelines, the Pneumatic Tube Magnet uses a direct-flow configuration to ensure uninterrupted material movement while capturing ferrous particles from powders, pellets, granules, and regrind. Its small footprint and streamlined design make it ideal for tight processing areas or point-of-entry inspection.

Simple to clean and easy to install, the Pneumatic Tube Magnet is an excellent choice for industries such as plastics, food processing, pet food, chemicals, and pharmaceuticals where product purity, compliance, and equipment protection are priorities.

Benefits of the Pneumatic Tube Magnet From Magnetic Products, Inc

-

High-Intensity Rare Earth Magnetic Tube

Equipped with a powerful neodymium (NdFeB) magnetic cartridge capable of capturing fine and weakly magnetic ferrous particles, including metal dust and shavings commonly found in regrind or bulk powders.

-

Compact, In-Line Design

Small and cylindrical, the tube magnet installs directly into pneumatic conveying lines without adding significant bulk or disrupting airflow, making it ideal for applications with limited space or tight processing layouts.

-

Low Pressure Drop

The direct inline design allows the product to flow around the magnetic tube with minimal restriction or turbulence. This ensures high throughput and efficient conveying without compromising magnetic separation efficiency.

-

Durable, Sanitary Construction

Built with all-welded 304 or 316 stainless steel for resistance to corrosion and wear. Internal surfaces can be polished to meet food or pharmaceutical standards. FDA-compliant gaskets are available for hygienic installations.

-

Manual-Clean Access Port

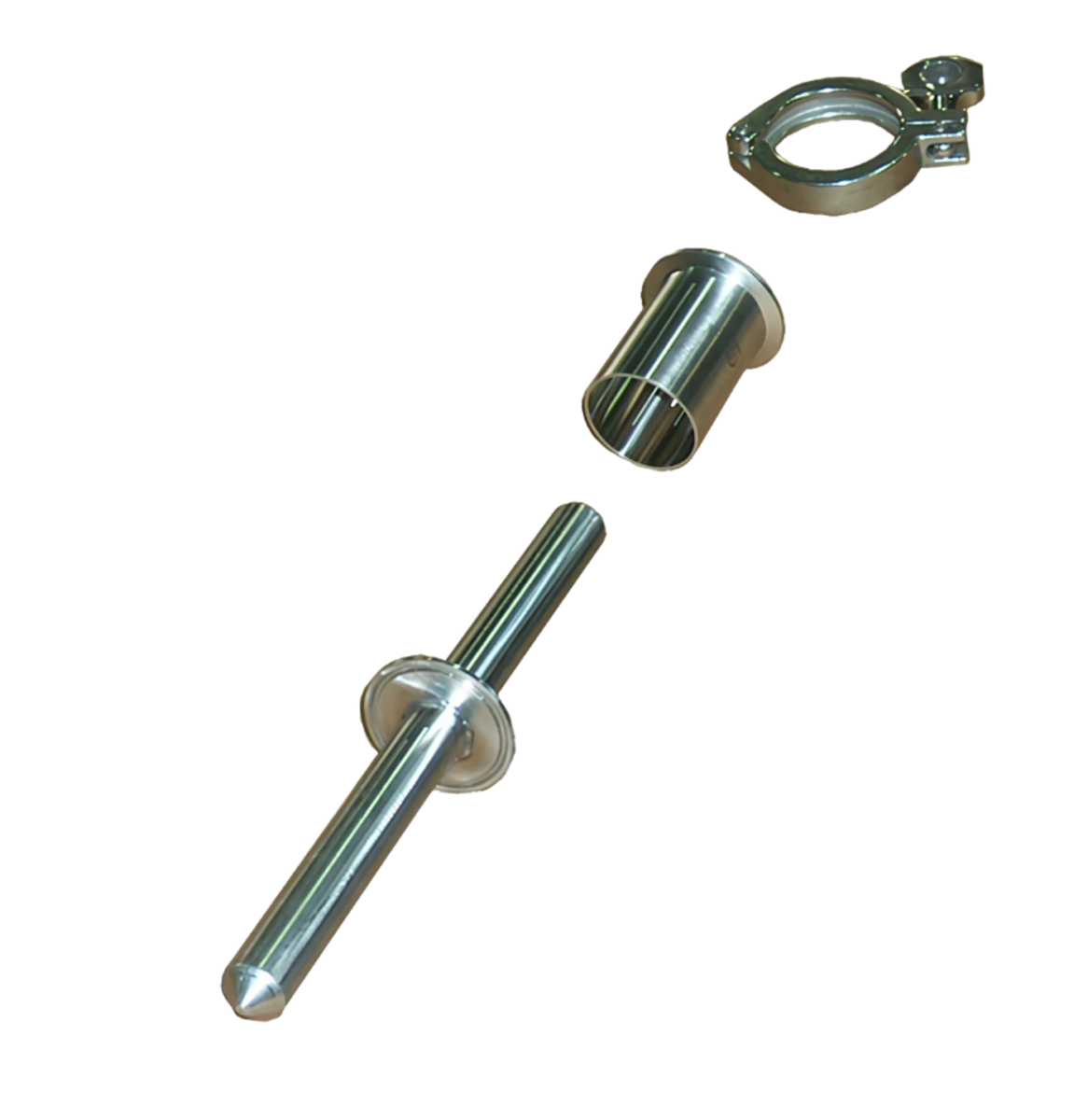

Features a simple pull-out design for easy removal and cleaning of the magnetic cartridge. Cleaning is quick and requires minimal tools, helping maintain productivity without the complexity of automated systems.

-

Easy Retrofit and Installation

Available in multiple pipe diameters and fitting types (clamp, flange, tube), the Pneumatic Tube Magnet can be quickly installed into new or existing pneumatic systems. Standard and custom configurations are available.

-

Protects Downstream Equipment

Prevents metal fragments from reaching expensive processing equipment, reducing the risk of damage, unplanned maintenance, and costly production downtime.

-

Supports Regulatory Compliance

Available with sanitary finishes and documentation to support food-grade and pharmaceutical compliance with FDA, USDA, and cGMP requirements.

Pneumatic Tube Magnet Product Details

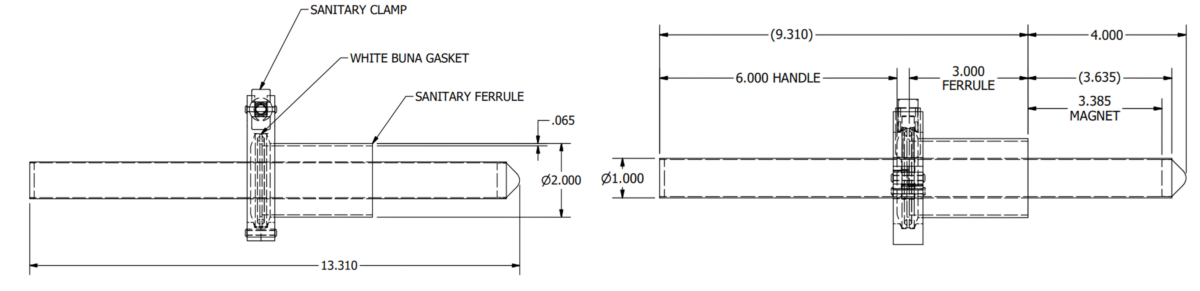

The MPI Pneumatic Tube Magnet is designed to be inserted directly into a pressurized pneumatic conveying line, where dry, free-flowing materials such as powders or pellets are transported under air pressure.

Installation in Conveying Line

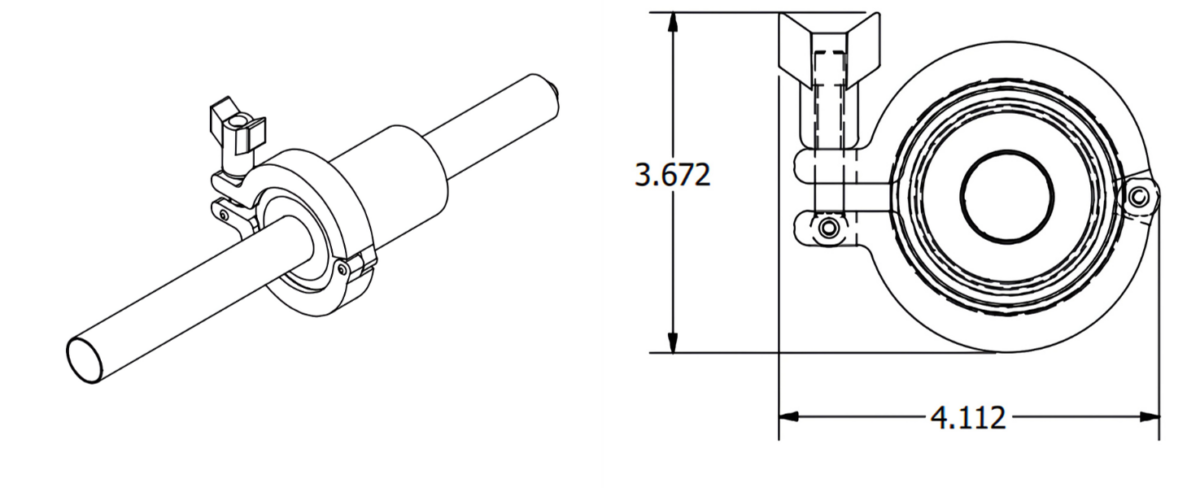

The magnet is installed inline using tri-clamp, flanged, or tube-end connections, in either a vertical or horizontal orientation. Its cylindrical body matches the diameter of the conveying pipeline for a seamless fit.

Product Flow and Magnetic Exposure

As material is pneumatically conveyed through the tube, it flows around or over the central magnetic cartridge inside the housing. The rare-earth magnet creates a strong magnetic field that reaches the product stream.

Ferrous Contaminant Capture

Any ferrous particles — including metal flakes, rust, filings, or tramp iron — are attracted to and held on the surface of the magnetic tube. Clean product continues through the system without obstruction.

Manual Cleaning Cycle

At scheduled maintenance intervals:

The system is shut down, and pressure is relieved.

The magnetic tube is removed through a sealed access port or pull handle.

Ferrous contaminants are wiped or scraped off manually and discarded.

Reinstallation

The magnet is returned to the housing, resealed, and the system resumes conveying. The entire process is simple, low-cost, and reliable.

This non-intrusive design makes the Pneumatic Tube Magnet an excellent fit for facilities looking to enhance product protection with minimal process disruption.

Pneumatic Tube Magnet Specification Table

US Customary Units

| ILMT 04 | ILMT 06 | ILMT 08 | ILMT 10 | ILMT 12 |

|---|---|---|---|---|

| 4 IN. | 6 IN. | 8 IN. | 10 IN. | 12 IN. |

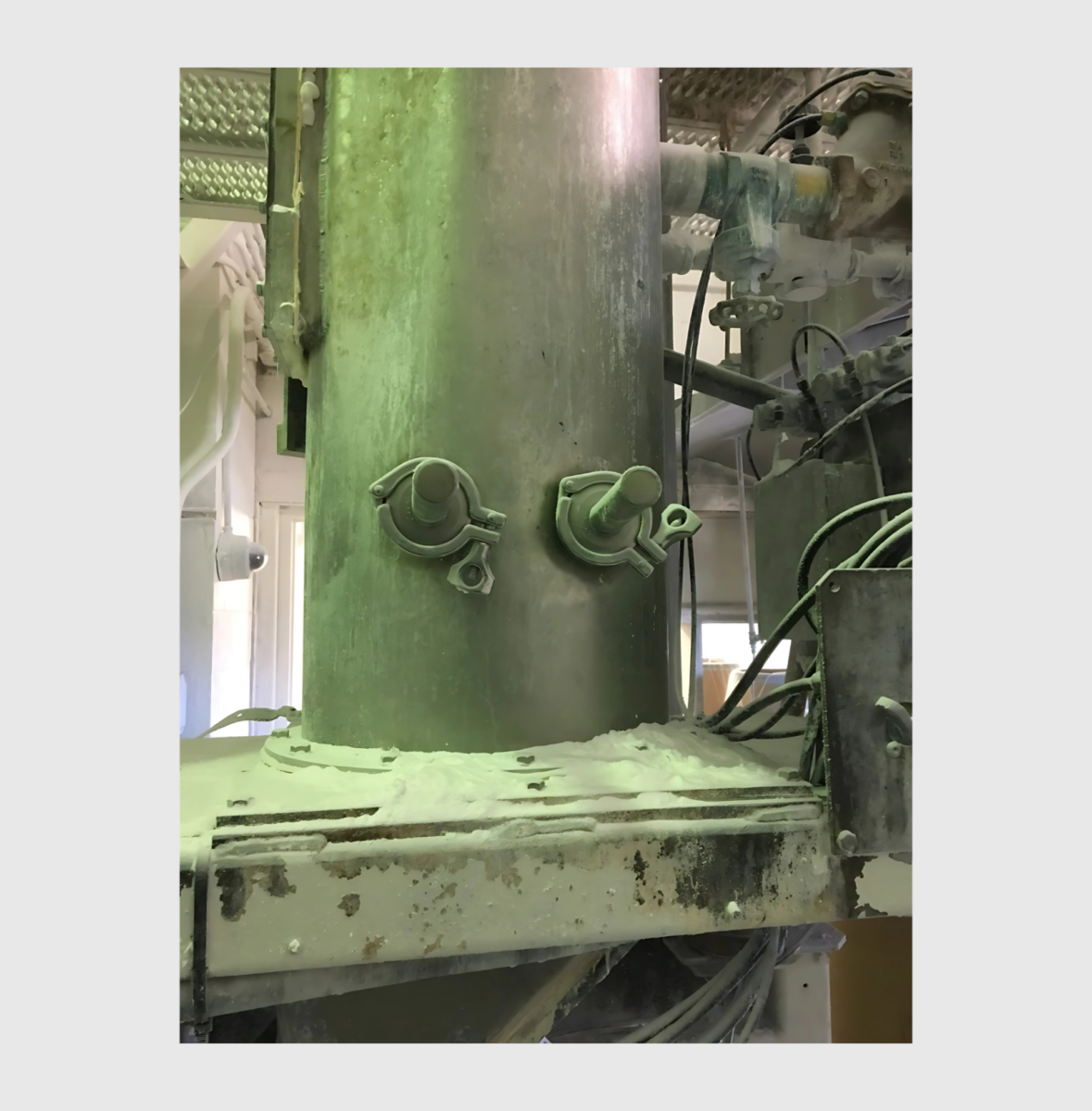

Pneumatic Tube Magnet Installations & Variations

Inline Magnetic Tube Specified for Air Conveyed Vertical Transfer Line

Horizontality Installed Dual Inline Magnetic Tubes in Food Processing Powder Application

Inline Magnetic Tube with Custom Couple Design for Narrow Transfer Line