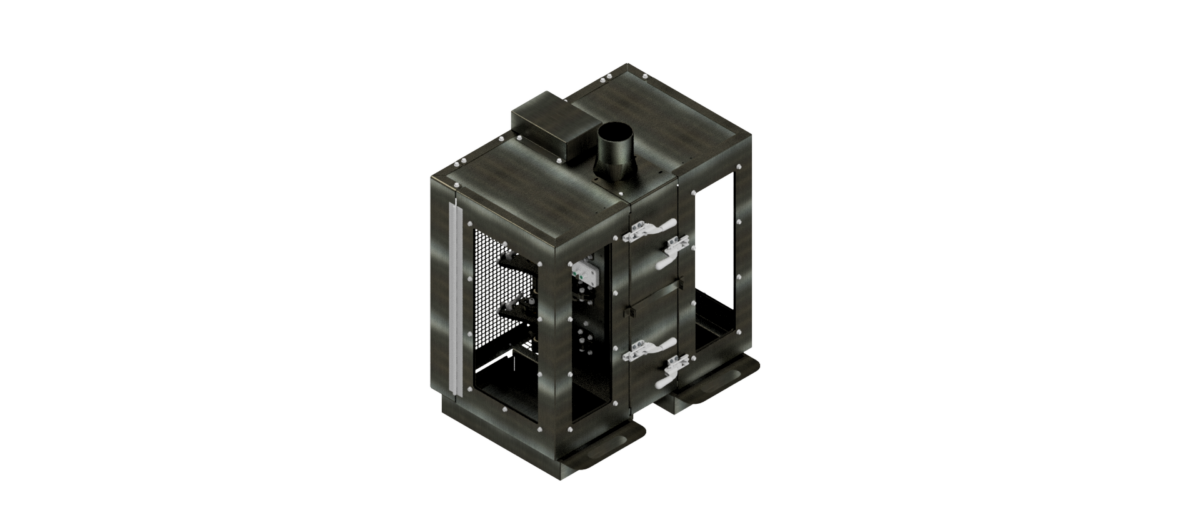

High-Performance Self-Cleaning Magnet for Pneumatic Conveying Systems

The patented MPI Pneumatic Wave™ Magnet is a next-generation self-cleaning magnetic separator for dry, free-flowing materials conveyed in high-velocity, pressurized pneumatic transfer systems. Purpose-built for industries where maximum separation performance, sanitary design, and minimal maintenance downtime are essential, the Wave™ Magnet captures ferrous contaminants from powders, grains, pellets, and regrind without interrupting production.

Unlike conventional pneumatic magnets that rely on manual or drawer-based access, the Wave™ Magnet features a fully enclosed, automated self-cleaning mechanism that uses a pneumatic linear actuator to remove captured metal from high-intensity rare-earth magnetic tubes via a sanitary stripper plate. It is engineered for vertical and horizontal inline installations in sanitary or industrial environments, including food, pet food, plastics, pharmaceuticals, and chemicals.

Offering unmatched contaminant removal efficiency, rapid cleanout cycles, and compliance-ready hygienic construction, the Wave™ Magnet is MPI’s most advanced inline pneumatic magnetic solution.

Benefits of the Wave™ Self-Clean Pneumatic Line Magnet From Magnetic Products, Inc

-

Fully Automated Self-Cleaning

The integrated pneumatic actuator powers a sanitary stripper plate that automatically removes collected ferrous contaminants from the magnetic tubes, discharging them through a sealed chute, without stopping the conveying process.

-

High-Efficiency Magnetic Separation

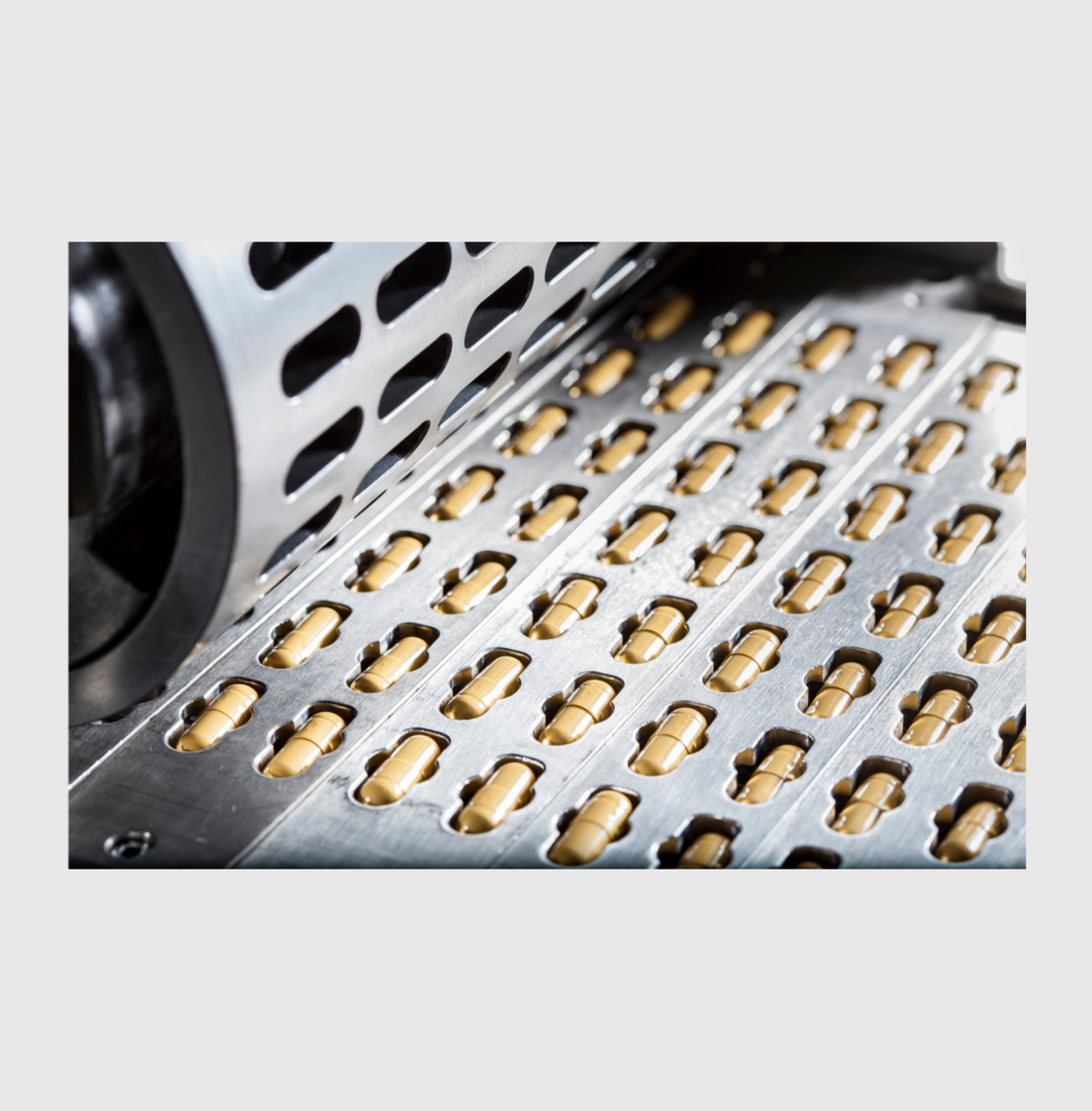

Five high-strength rare-earth magnetic tubes (standard 1" diameter) arranged on 2.5" centers create an ultra-dense magnetic field across the product stream, effectively capturing even the finest and weakest magnetic particles.

-

Streamlined, Enclosed Design

Unlike drawer magnets, the Wave™ Magnet uses a fully enclosed magnetic array inside a sealed housing. This design minimizes product hang-up, supports clean-in-place (CIP) compatibility, and ensures smoother airflow and easier sanitation.

-

Hygienic, Sanitary Construction

Constructed from 304 or 316 stainless steel with polished internal surfaces and FDA-approved gaskets, the Wave™ is ideal for food and pharmaceutical applications requiring cGMP and HACCP compliance.

-

High-Pressure System Compatibility

Built to handle high-velocity dilute-phase pneumatic systems, the Wave™ maintains internal system pressure and withstands harsh conveying conditions while maintaining efficient magnetic separation.

-

Minimal Downtime, Labor-Free Maintenance

Operators no longer need to open housings or remove magnetic cartridges. The quick, hands-free cleaning cycle reduces labor, downtime, and contamination risk—ideal for frequent cleanouts or allergen changeovers.

-

Easy System Integration

The compact, cylindrical design fits into existing conveying lines using standard or custom pipe connections. It is suitable for vertical drop lines or horizontal runs with minimal pressure drop.

-

Protects Product Quality and Equipment

By removing tramp metal and ferrous fines from the product stream, the Wave™ Magnet safeguards downstream equipment like extruders, packaging machines, and blenders, while preserving product purity.

Wave™ Self-Clean Pneumatic Line Magnet Product Details

The MPI Pneumatic Wave™ Magnet operates within pressurized pneumatic conveying systems where dry, bulk materials are transferred at high velocities. It’s engineered to offer continuous magnetic separation without requiring system shutdowns for cleaning.

Inline Installation

The Wave™ Magnet is installed directly into a vertical or horizontal conveying line using standard flanges or clamps. It forms a sealed, high-integrity section of the pneumatic system.

Magnetic Separation Zone

Five staggered rare-earth magnetic tubes are arranged across the flow path inside the housing. As the product moves through the magnet, ferrous contaminants are pulled to the tube surfaces, held firmly in place by the magnetic field.

Self-Cleaning Process

At timed intervals or via operator signal:

- A pneumatic linear actuator retracts the magnet cores from inside the tubes.

- As the magnetic field collapses, a sanitary stripper plate sweeps across the tubes, mechanically dislodging the captured metal.

- Ferrous debris is pushed to and ejected through an external discharge chute, safely separated from the product flow.

Return to Operation

Once cleaning is complete (usually in under a minute), the magnet cores return to the operating position, reestablishing the magnetic field. The product stream remains uninterrupted during the entire process.

This process ensures that metal is continuously removed from the system without stopping production or exposing operators to contamination risks.

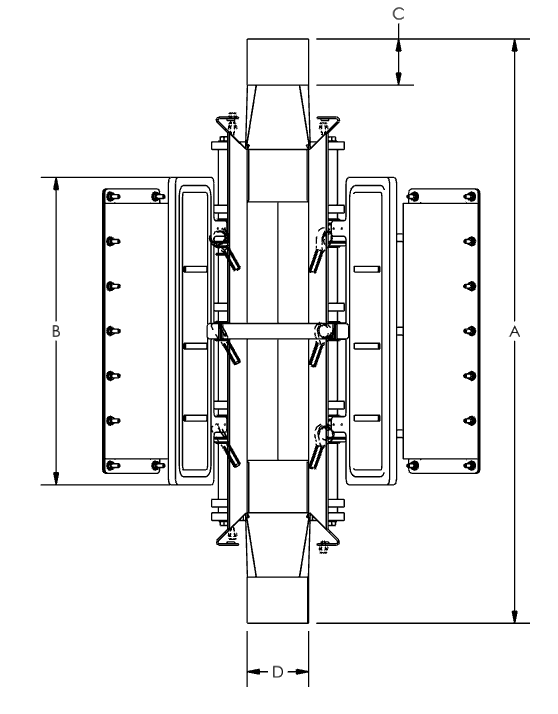

Wave™ Self-Clean Pneumatic Line Magnet Specification Table

US Customary Units

| MODEL # | (A) OVERALL LENGTH (IN.) | (B) MAGNET LENGTH (IN.) | (C) COLLAR LENGTH (IN.) | (D) COLLAR DIAMETER (IN.) | APPROX. WEIGHT (LBS.) |

|---|---|---|---|---|---|

| WAVE 2 IN. | 38 | 24 | 3 | 2 | ~329 |

| WAVE 3 IN. | 38 | 24 | 3 | 3 | ~329 |

| WAVE 4 IN. | 38 | 24 | 3 | 4 | ~329 |

Wave™ Self-Clean Pneumatic Line Magnet Installations & Variations

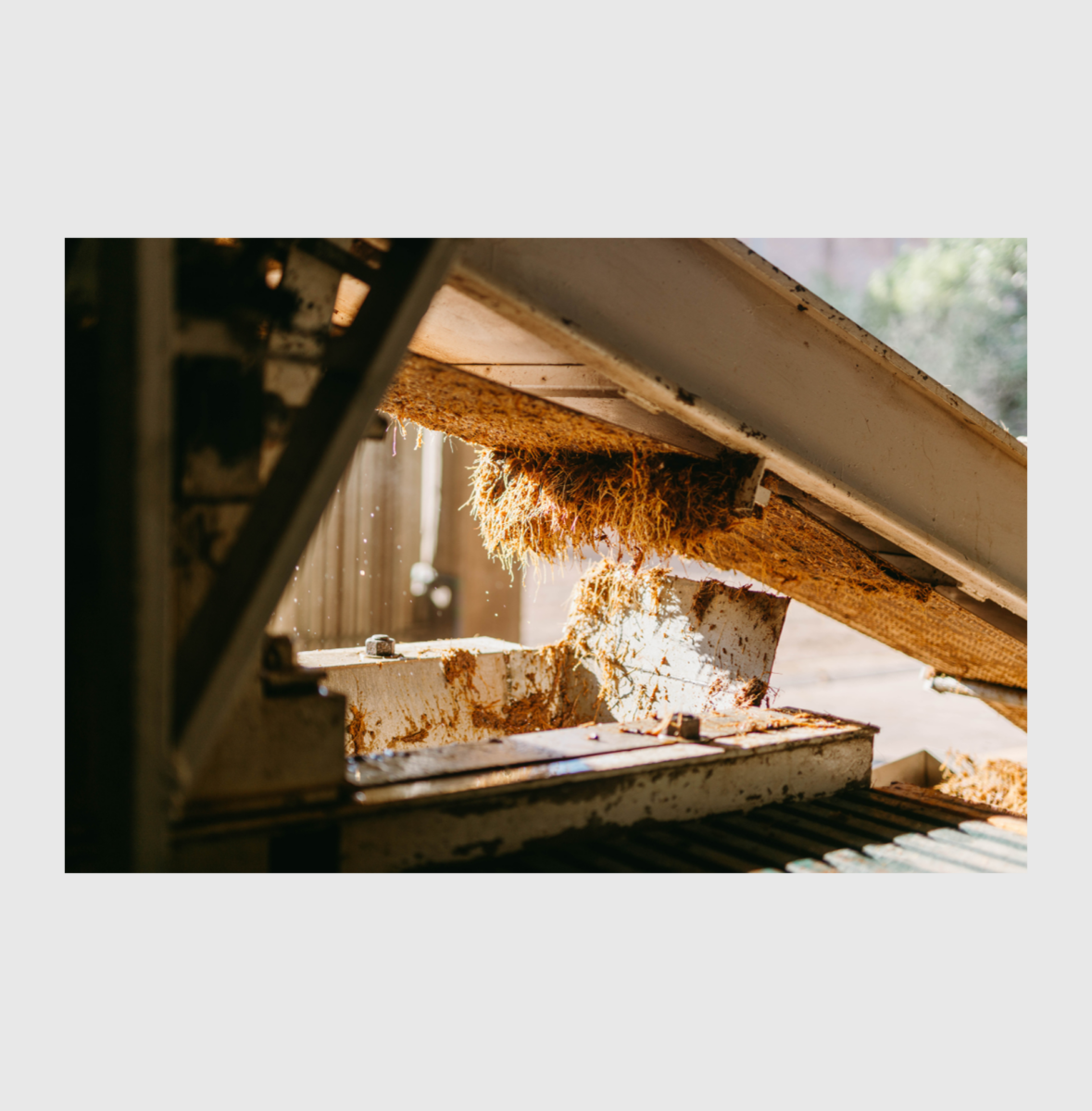

Ideal for Semi-Dried Meat Meal Processing in the Pet Food Industry

Ideal for Food Processing Applications Prone to Bridging

Perfect for Protecting Product Purity in Sensitive Nutraceutical and Pharmaceutical Formulations