Continuous Inline Contaminant Detection for Pumped Liquids and Slurries

The MPI Liquid Product X-Ray Inspector is a specialized inline detection system engineered to identify foreign objects in liquid, slurry, and paste-like products as they move through a pressurized pipeline. Designed for high-throughput liquid handling environments in food, dairy, pet food, nutraceutical, and pharmaceutical processing, this system ensures product safety at the earliest possible stage—before filling or packaging.

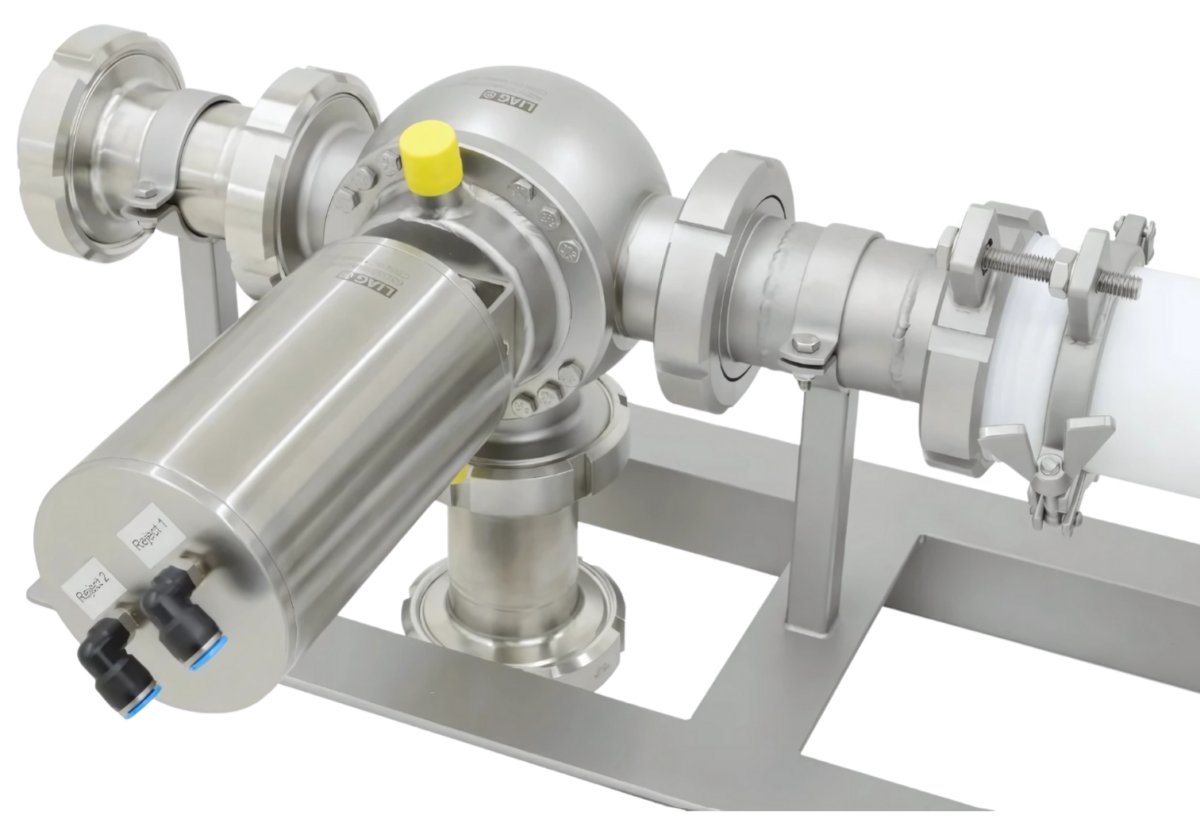

Using advanced single-beam or dual-energy X-ray detection and a hygienic, CIP-compatible design, MPI’s Liquid X-ray system delivers reliable, noninvasive inspection of viscous and opaque products. It identifies a wide range of contaminants—including glass, metal, bone, stone, dense plastic, and rubber—regardless of product density, turbidity, or flow rate.

Fully integrated with automatic reject valves, this system enables real-time contaminant removal, protects downstream equipment, and reduces waste while supporting the highest food safety and regulatory standards.

Benefits of the Liquid Product X-Ray Inspector From Magnetic Products, Inc

-

Inline Contaminant Detection in Liquid Pipelines

Designed for pumped or flowing liquids, pastes, sauces, slurries, and emulsions, it inspects products inside closed piping systems, eliminating contamination before the packaging phase.

-

Broad-Spectrum Contaminant Identification

Advanced X-ray image analysis, even in opaque or high-fat liquids, detects a wide range of foreign objects—including glass shards, metal fragments, dense plastics, bones, stones, and rubber.

-

Real-Time, Non-Disruptive Inspection

It inspects products in motion without interrupting the flow. High-speed analysis enables continuous production with no bottleneck, supporting high-throughput operations.

-

Sanitary, CIP-Compatible Design

Hygienic 304/316 stainless steel construction with clean-in-place (CIP) compatibility and crevice-free pipe connections. Ideal for use in dairy, beverage, baby food, and other hygiene-sensitive environments.

-

High-Precision Reject Valve Integration

It connects with pneumatic diverter valves to instantly remove contaminated product into a waste tank or return line. This ensures that only clean product continues downstream to fillers or packaging.

-

Adaptive X-Ray Imaging for Variable Densities

Uses dual-energy or tuned-frequency technology to optimize detection based on product consistency (from water-like to viscous) and ingredient density, reducing false rejects.

-

Compact Footprint for Easy Integration

The system is installed directly into the existing pipeline infrastructure with minimal space requirements. It is available in vertical or horizontal layouts to fit the processing line design.

-

Audit-Ready Controls and Data Logging

Automatically records inspection data, rejection events, operator logins, and image captures. Fully supports HACCP, FSMA, GFSI, and 21 CFR Part 11 requirements for regulated industries.

Liquid Product X-Ray Inspector Product Details

MPI’s Liquid Product X-Ray Inspector operates within a closed, pressurized pipeline, where liquid or semi-liquid products are transported via pumps between production stages. It uses focused X-ray technology and real-time image processing to identify contaminants without halting product flow.

Installation in Product Line

The system is installed into a stainless-steel pipeline, typically 2"–4" diameter, at a point before filling or downstream from mixing. It includes an X-ray inspection chamber, a control panel, and a reject valve interface.

X-Ray Beam and Image Capture

As liquid flows through the inspection chamber:

- A narrow, collimated X-ray beam passes through the product.

- A high-speed detector array captures data about product density in real time.

Image Processing and Analysis

Intelligent software analyzes variations in density, contrast, and shape to detect contaminants. It differentiates between normal product variations and foreign objects using:

- Dual-energy filtering for improved discrimination

- Self-learning algorithms for optimized detection by product type

Contaminant Identification and Rejection

If a contaminant is detected:

- The system immediately sends a signal to a high-speed diverter valve

- A small quantity of contaminated product is diverted into a waste tank or reject line

- Clean product continues downstream without delay

Data Logging and Quality Assurance

Every detection event is recorded, including:

-

X-ray image of the contaminant

-

Timestamp

-

Product ID or batch code

-

Operator interactions and alarm states

This data supports audits, traceability, and compliance with food safety plans.

Liquid Product X-Ray Inspector Specification Table

US Customary Units

| MODEL FEATURE | XRAY SHARK® XD08-H1-PIPE |

|---|---|

| X-Ray Source | Single beam x-ray generator with max. 80kV (480W), variable in voltage + current |

| Radiation Leakage | 3 µSv/h or less, at 10 cm outside cabinet doors using all safety devices |

| Safety | Special product pipe, magnetic safety switches at cabinet doors and tunnel hatches, emergency stop push button, emergency stop in/out interfaces to safety circuits of production line, X-ray off key switch |

| X-Ray Detection | Low noise 408 mm line scan CCD, diode pitch 0.8 mm (optional 0.4 mm) |

| Cooling | Highly efficient, silent DC filter fans |

| Housing Finish | Stainless steel grade AISI 304 / DIN EN 1.4301 (X5CrNi18-10) |

| Enclosure Rating | IP54 (according to IEC 60529), including touch panel and fans |

| Pipe Type | 80 mm, stainless steel 304 and POM white (FDA) |

| Pump/Flow Speed | 0.05 to 2 m/sec |

| Flow Rate | Max. 100 pieces per minute |

| Product Memory | 255 different product set-ups |

| Display | 17“ color-TFT capacitive touchscreen |

| Inspection Features | Autocalibration, auto adaption to density distribution, density, hard contrast, soft contrast, masking technology, SuperContrast, SizeFilter, AutoEdge masking, images AutoSave/Load, Multi Segment Inspection, metal can and foil inspection, fill quantity, generator energy by product, password protection |

| Data Transfer and Reporting | Ethernet for remote support via internet, USB for external keyboard/ mouse/ memory stick |

| Weight | 0.5 t |

| In/Outputs | Programmable outputs (contamination, ready, Emergency OFF) Programmable inputs (Emergency OFF, wake up, optional control signals) |

| Power Supply | 1ph, 230 VAC +/- 10%, 50/60 Hz, 1.0 kW full operation |

| Compressed Air Supply | Without pusher 0 MPa (0 bar/0 psi) bar With rejection system 0,6 MPa (6 bar/87 psi) |

| Enviornmental Conditions | 10° to +25°C / +50°F to 77°F, with relative humidity max 90%, non-condensing (optional external cooling device) |

| Conformity | CE, compliant to german x-ray regulations, specific adaptation for other countries |

Liquid Product X-Ray Inspector Installations & Variations

Liquid Product X-Ray Inspector Used to Process Slurry in Pet Food Application

Liquid Product X-Ray Inspector Installed in Dairy Processing for Pumped and Flowing Milk

Adaptive Liquid X-Ray Imaging Installed for Variable Liquid Food Densities