Impact Resistant Slider Bed

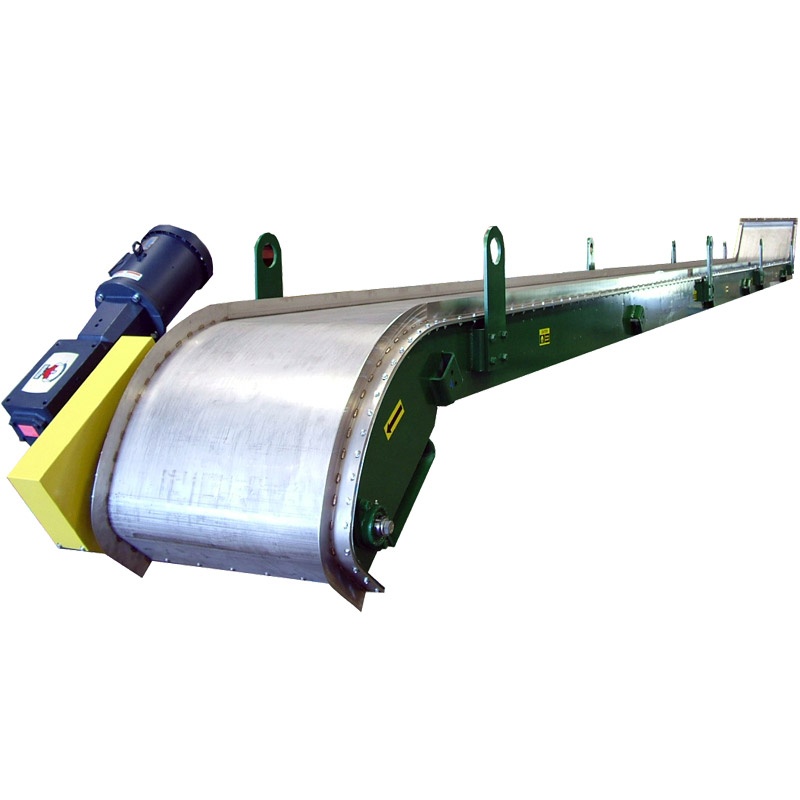

MPI’s Beltless Magnetic Conveyor provides a robust and low-maintenance solution for transporting sharp, oily, hot, or abrasive ferrous materials without traditional belts. It employs powerful magnets attached to a moving chain assembly beneath a smooth stainless-steel slider bed, ensuring efficient material handling while minimizing issues like belt wear and misalignment. The conveyor is ideal for metalworking environments, effectively transporting metal scrap, turnings, chips, and fasteners. With several models and configurations available, including options for feeders and hoppers, the BLM series is designed for rugged use and operational uptime. Features such as a liquid-tight, sealed housing, an internal self-adjusting tension system, and a durable slider bed made from stainless steel contribute to its maintenance-free operation. American-made drive packages further enhance its reliability and performance.

Benefits of the Beltless Magnetic Conveyor From Magnetic Products, Inc

-

No External Belt to Maintain

Eliminates issues with belt wear, tracking, or slipping—ideal for oily or abrasive environments.

-

Fully Enclosed Magnetic Circuit

Sealed housing protects all moving parts from debris, coolant, and contaminants.

-

Ideal for Sharp or Hot Scrap

Handles materials that typically damage belts, including hot metal chips or jagged stampings.

-

Durable Stainless-Steel Slider Bed

Provides a smooth, wear-resistant surface for conveyed materials to glide over.

-

High Magnetic Holding Force

Powerful magnets reliably move ferrous materials—even up steep inclines.

-

Continuous Operation with Low Downtime

Chain-driven magnet assembly ensures dependable, 24/7 performance with minimal service needs.

-

Compact Footprint

Custom-fit configurations accommodate tight spaces or integrate into existing equipment layouts.

-

Reduced Operating Costs

Fewer components and no belts mean less frequent maintenance and longer service life.

Beltless Magnetic Conveyor Product Details

Powerful permanent magnets move ferrous metal objects below a nonmagnetic stainless steel slider bed. The liquid-tight, sealed conveyor housing can be completely submerged in machine reservoir tanks, and the internal self-adjusting take-up system eliminates the need for maintenance. No external moving components make the beltless magnetic conveyor the safest way to convey ferrous metal parts and scrap.

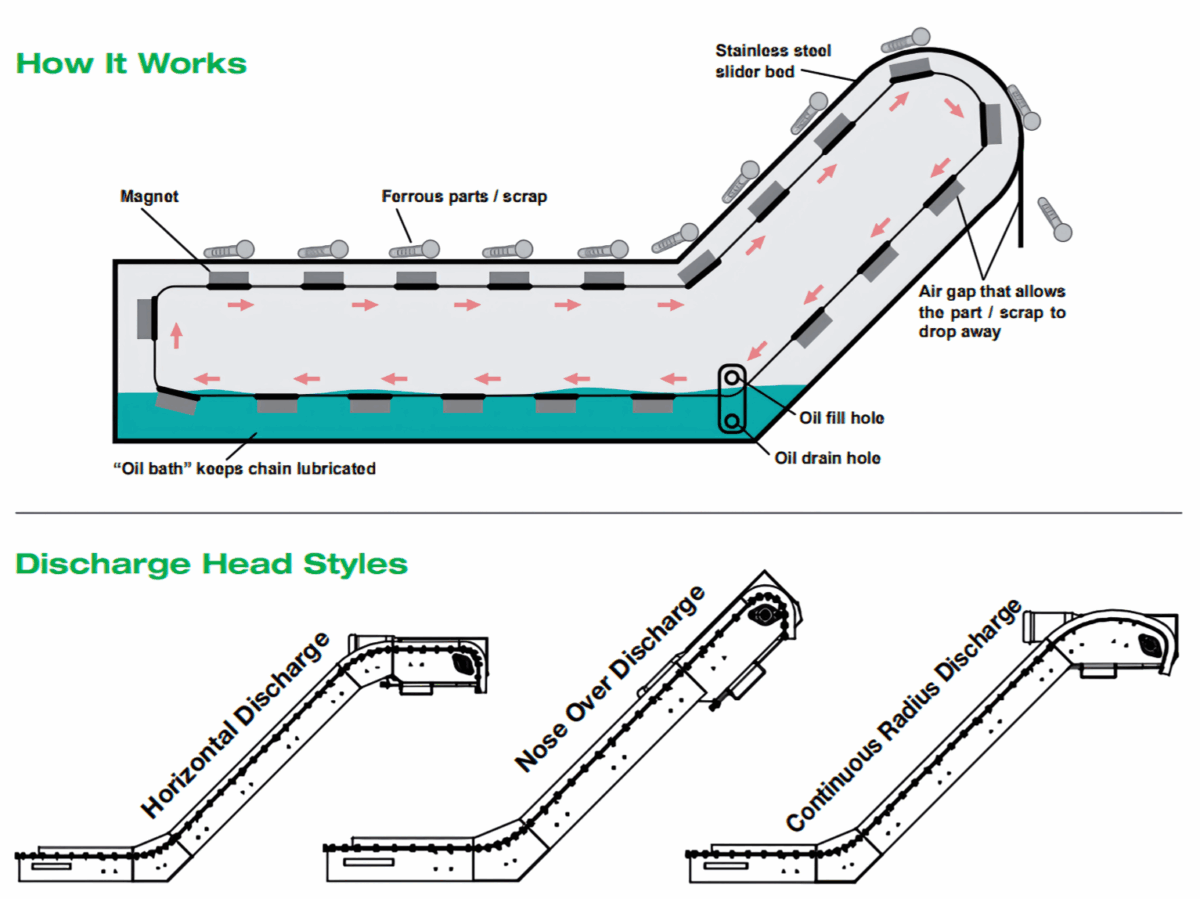

Loading Area

Ferrous scrap or parts are introduced onto the stationary slider bed surface at the intake end.

Magnetic Transfer System

Below the surface, a series of powerful magnets are mounted to a continuous chain-driven assembly.

Movement Under the Surface

As the chain moves, magnets glide beneath the slider bed, pulling the ferrous materials along from above.

Incline/Discharge

Materials are conveyed horizontally or up an incline—held firmly by magnetic force—until they reach the discharge point.

Release Zone

The magnetic field disengages as the magnets recirculate, allowing the conveyed materials to fall away cleanly at the discharge end.

Loop Reset

The magnetic carriers return underneath the housing, ready to begin the next cycle.

Beltless Magnetic Conveyor Specification Table

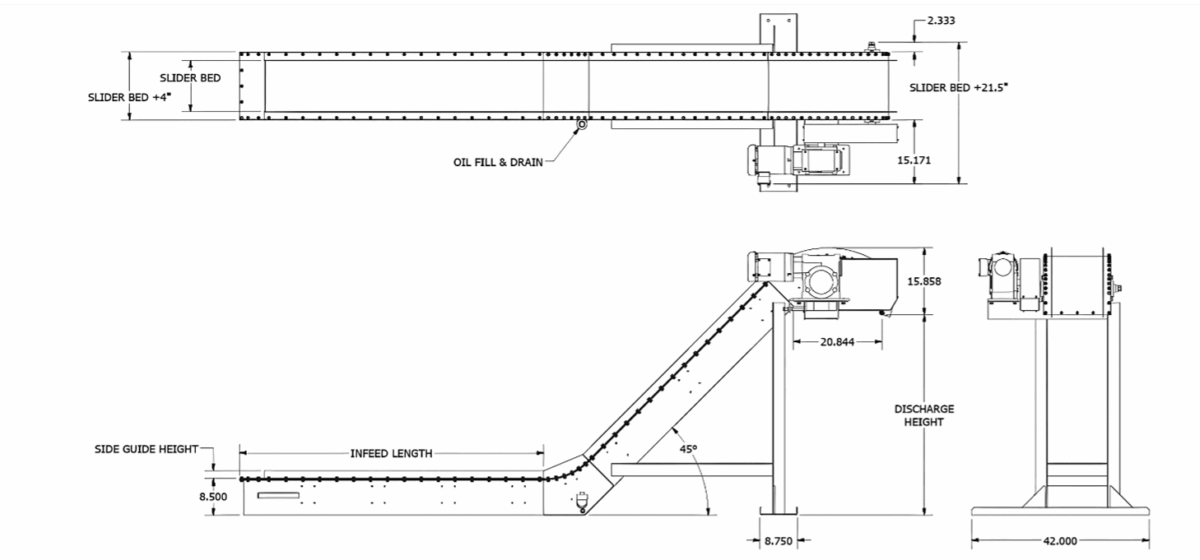

Standard In-Feed Length: 30″ or larger / Self-Adjusting Take-Up: Included / Slider Bed Thickness: 12 or 7 Gauge, depending upon width / Slider Bed Width: 6″ to 24″ / Angle of Incline: 0 to 90° (15° increments) / Speed: 45 FPM / Magnet Material: Ceramic (rare earth, as required)

| MODEL FEATURE | 600 SERIES | 800 SERIES | 1200 SERIES |

|---|---|---|---|

| Body Depth (in.) | 6.5 in. | 8.5 in. | 13.875 in. |

| Magnetic Capacity | * | ** | *** |

| Magnet Centers (in.) | > 5 in. | > 6 in. | > 8 in. |

| Chain | #2052 | #2062 | #2082 |

| Body Construction | 11 Guage | 11 Guage | 7 Guage |

Beltless Magnetic Conveyor Installations & Variations

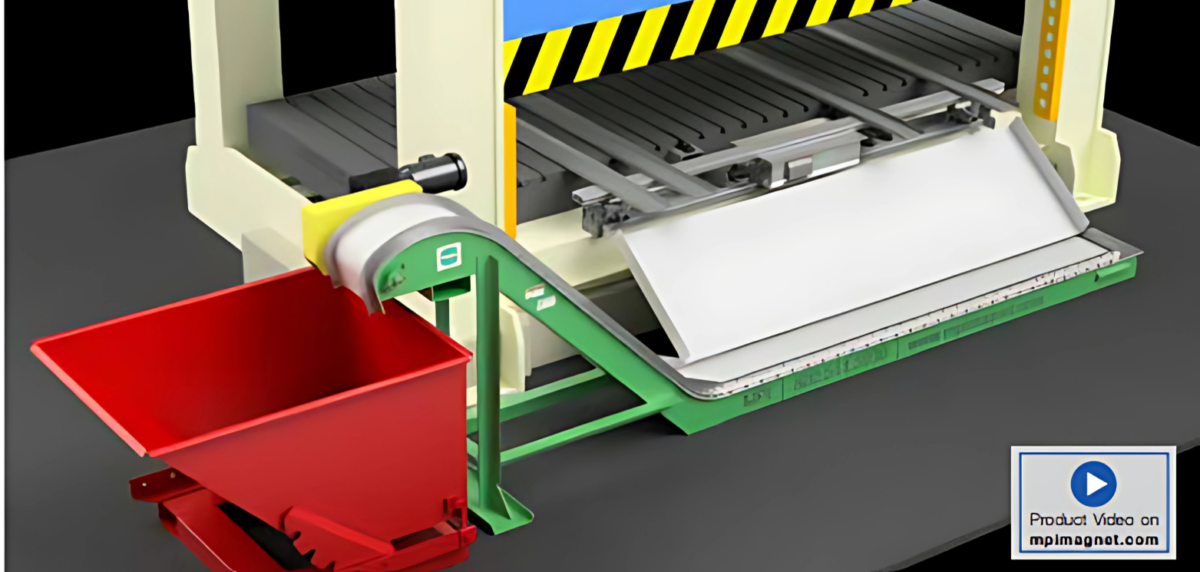

BLM for Conveying Finished Ferrous Fasteners to Bins in Metal Fastener Production

BLM for Handling Hot Jagged Stampings That Would Destroy a Traditional Belt

BLM in Precision Metalworking to Remove Steel Chips and Turnings from CNC Lathes