Verify Metal Detector Operation

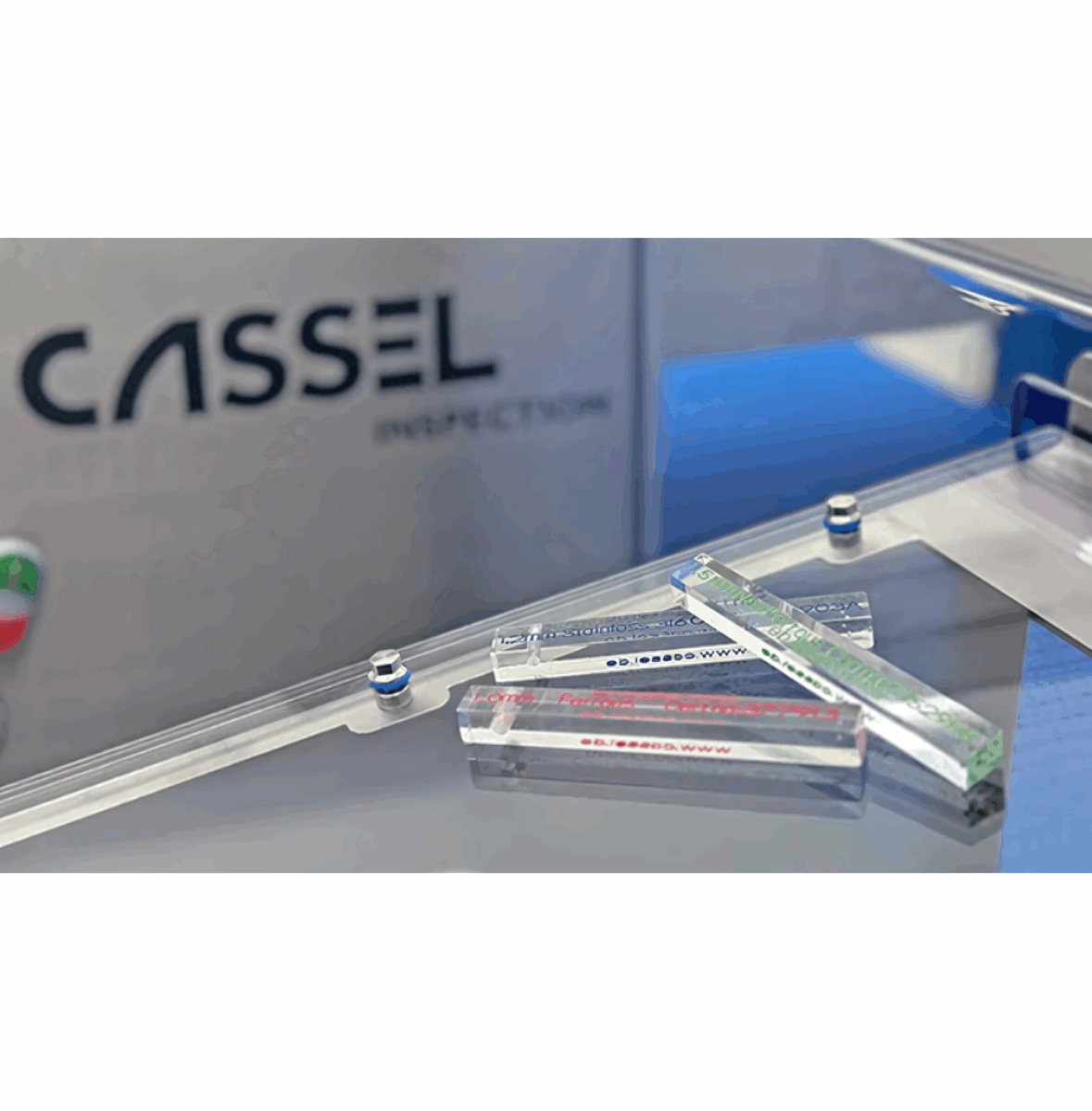

MPI’s Metal Detector Test Sticks are high-precision calibration tools designed to verify the performance of metal detection systems across food, pharmaceutical, plastics, and general manufacturing lines. Each stick encases a certified, contaminant-sized metal sphere—ferrous, non-ferrous, or stainless steel, within a durable, food-grade plastic housing, ensuring consistent test results without product contamination. Available in various sizes and colors for easy identification, MPI test sticks are essential for routine validation, compliance with HACCP and GFSI protocols, and internal quality assurance programs. Use them to confirm sensitivity, detectability, and reject functionality of tunnel, gravity, and pipeline metal detectors.

Benefits of the Test Sticks From Magnetic Products, Inc

-

Certified Metal Contaminants

Encapsulated ferrous, non-ferrous, or stainless-steel spheres with traceable regulatory and audit compliance certification.

-

Durable, Food-Safe Construction

Made from FDA-compliant, shatter-resistant plastic that can withstand harsh plant environments without contaminating product flow.

-

Color-Coded by Material Type

Simplifies operator use and ensures quick visual identification of test metal type (e.g., red = ferrous, green = non-ferrous, blue = stainless).

-

Consistent and Repeatable Testing

Precisely placed test spheres guarantee uniform detection results across operators and test cycles.

-

Supports HACCP, FSMA, and GFSI Compliance

Critical tool for validating that metal detectors meet required sensitivity levels and can trigger proper rejection mechanisms.

-

Compatible with All Detector Types

Works with gravity, belt, and pipeline metal detectors across most brands and configurations.

-

Custom Sizes Available

Spheres are available in sizes from 0.3 mm to 3.5 mm (and larger) to match specific sensitivity settings and industry requirements.

-

Traceable Documentation Included

Each test stick ships with a certificate of conformity that includes sphere size, material, and testing standard reference.

Test Sticks Product Details

-

Choose the correct test stick based on the detector type and desired sensitivity verification (e.g., 1.5 mm stainless steel for a food line).

-

Insert or pass the test stick through the detection zone during normal or controlled operation, depending on your QA protocol.

-

Observe the detector’s response—the unit should trigger an alarm or rejection event consistent with the test setup.

-

Record the results in your inspection log or QA database, noting the metal type, sphere size, detector used, and outcome.

-

Repeat the test at scheduled intervals to verify ongoing detector performance and compliance.

-

Use different test stick materials (FE, NFE, SS) periodically to ensure full-spectrum metal detection validation.