Magnetic Separation Solutions for the Food Processing and Packaging Industries

In food manufacturing, foreign metal contamination can originate from raw material sources, equipment wear, conveying systems, or manual processing errors. MPI’s magnetic separators and detection technologies are mission-critical for:

- Complying with FDA, USDA, FSMA, and GFSI regulations

- Protecting consumer health

- Preventing product recalls

- Maintaining brand integrity

MPI solutions are integrated across all key production stages—from raw ingredient receiving and bulk handling to grinding, mixing, forming, cooking, and final packaging—to remove ferrous and non-ferrous contaminants before the product reaches the consumer.

MPI’s magnetic separation, detection, and inspection technologies ensure safe, contaminant-free food from ingredient receiving to final packaging. Whether handling powders, pastes, liquids, or finished goods, MPI solutions:

- Prevent recalls

- Protect equipment

- Ensure FSMA/GFSI/HACCP compliance

- Support brand and regulatory standards

- Safeguard consumer health

| Stage | MPI Product | Purpose |

|---|---|---|

| Ingredient receiving | Plate magnets, drum separators | Remove bulk tramp metal from raw flour, grains |

| Pre-mix or weighing | Drawer-in-housing magnets, pneumatic drawers | Capture fine particles before batching |

| Liquid blending or cooking | Liquid trap magnets | Protect pumps and ensure sauce/paste purity |

| Pneumatic transfer | Self-cleaning drawer magnets | Maintain a contaminant-free flow between process steps |

| Form-fill-seal packaging | Metal detector, x-ray | Final contaminant screening before sealing |

| Retail QA | Metal detector/checkweigher combo | Prevent underweight or contaminated shipments |

Turnkey Solutions for Food Processors and Packaging From Magnetic Products, Inc

-

Prevents Recalls and Protects Consumers

Powerful magnets and metal detectors remove physical hazards such as screws, blades, or wire fragments—reducing the risk of product withdrawal or injury.

-

Ensures Regulatory and Audit Compliance

MPI products are designed to meet stringent sanitation, allergen control, and HACCP compliance standards, with traceable documentation and audit-ready performance.

-

Captures Even Fine and Weakly Magnetic Particles

High-intensity rare earth magnets capture fine, rust-like, or processing-induced particles often missed by standard filtration systems.

-

Sanitary, Food-Grade Construction

All contact surfaces are made of polished 304/316 stainless steel with food-safe gaskets, tool-free access, and welded seams for hygienic washdown environments.

-

Minimizes Downtime with Easy-Clean Designs

Quick-clean and self-clean models reduce cleaning time during sanitation cycles or product changeovers, supporting lean production goals.

-

Customizable for Wet, Dry, Liquid, or Pneumatic Lines

MPI solutions can be tailored to match specific ingredient formats, flow rates, or system layouts, accommodating powders, flours, granules, liquids, slurries, or vacuum transfers.

-

Supports Brand Integrity and Customer Contracts

Metal-free product ensures quality assurance for private label, contract manufacturing, and retail compliance with major grocery and foodservice customers.

-

Combined Systems for Complete Protection

MPI integrates magnetic separation, metal detection, and x-ray inspection into layered safety systems for full-spectrum contaminant detection.

How Does the Food Processing and Packaging Industry Use Magnets?

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

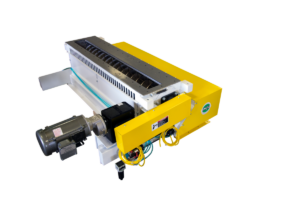

| Drawer-In-Housing Magnets (Manual-Clean, Quick-Clean, Self-Clean) | Gravity-fed chutes (e.g., flour, sugar, powders, grains) | Traps tramp iron and fine particles in dry ingredients | Prior to mixing, weighing, or bagging | Multiple rows of magnetic tubes filter product as it flows through housing |

| Pneumatic Line Drawer Magnets (Quick-Clean, Self-Clean) | Inline with vacuum transfer or pressurized powder systems | Remove contaminants during pneumatic conveying | Between silos, hoppers, mixers, or form-fill-seal stations | Magnetic cartridges capture contaminants in-stream without disrupting flow |

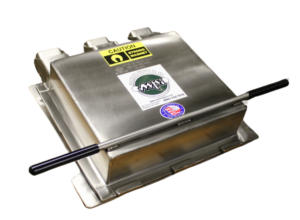

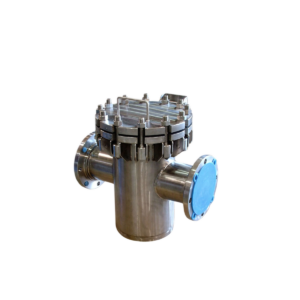

| Liquid Trap Magnets (Manual-Clean, Quick-Clean, Self-Clean) | Inline with liquid pipelines (e.g., sauces, soups, juices, slurries) | Protect pumps, valves, and fillers from ferrous particles | Before cooking, pasteurizing, or bottling | Magnetic tubes inside sealed housings attract particles as liquid flows |

| Plate Magnets and Magnetic Chutes | In vertical or sloped transitions for bulk ingredients | emove tramp metal during material drop or flow | Before conveyors, sifters, or mixers | Product passes near strong magnetic plates that trap debris |

| Magnetic Head Pulleys | On belt conveyors for baked goods, frozen foods, or produce | Automatically removes ferrous materials at discharge | After forming or sorting, before packaging | Pulley magnetizes surface to lift and discharge metal beneath |

| Metal Detectors (Tunnel or Conveyor Style) | On final inspection lines before case packing | Detect all metal types (ferrous, non-ferrous, stainless steel) | After packaging, forming, or batching | Metal presence triggers reject arm, air blast, or belt stop |

| Combination Metal Detector & Checkweigher | On retail pack-out lines | Detects metal and confirms package weight compliance | Final QA step before shipping | Dual inspection with rejection system for non-conforming products |

| X-Ray Inspection Systems (Packaged, Bulk, or Jarred Foods) | Inline for packaged foods or glass containers | Identifies glass, rubber, stone, or plastic not caught by magnets or detectors | Post-fill, post-seal, or pre-case pack | X-ray image processing identifies density irregularities and triggers reject |