Efficient Contaminant Removal with Fast, Tool-Free Cleaning

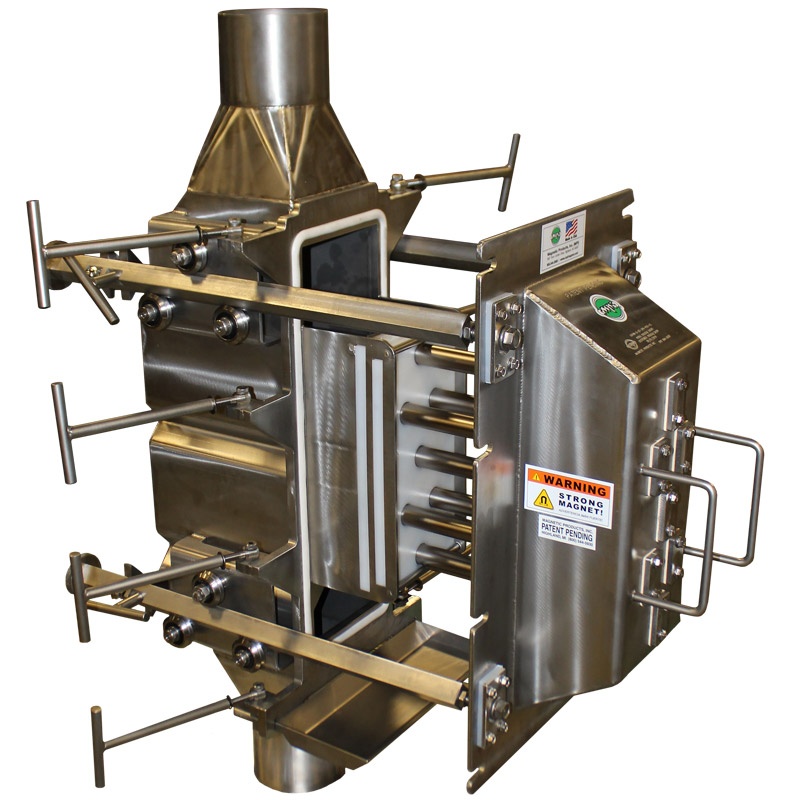

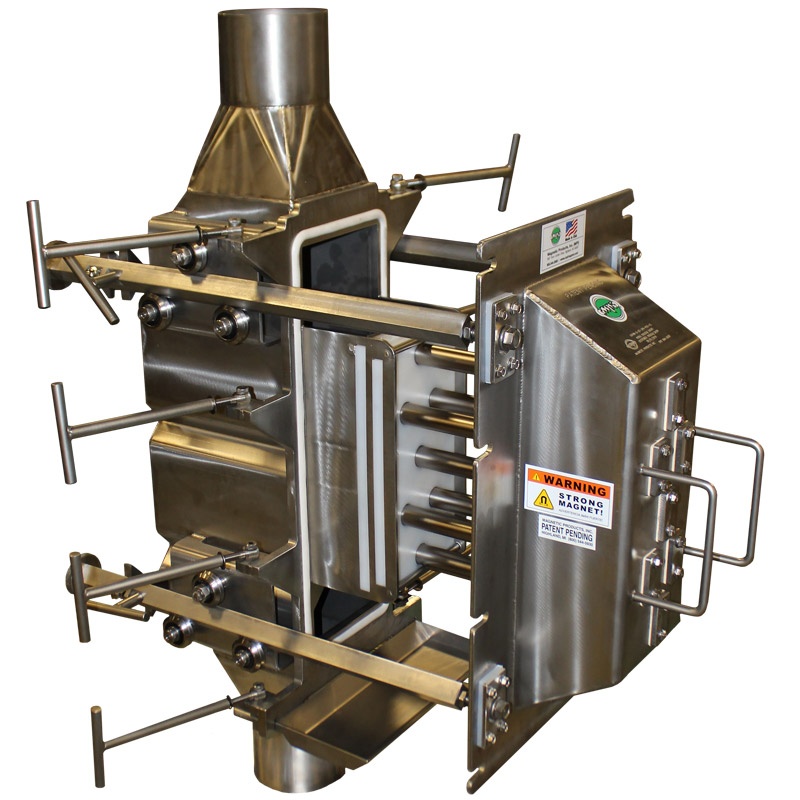

The MPI Quick-Clean Inline Pneumatic Drawer Magnet is designed for high-performance metal contaminant separation in pressurized pneumatic conveying systems. Engineered for processors who demand sanitary, efficient, and easy-to-maintain equipment, this inline magnet features powerful rare-earth magnetic tubes arranged in multiple rows to maximize contact with the product stream and ensure the capture of fine and weakly magnetic particles.

Constructed from durable stainless steel with dust-tight seals, the unit is ideal for use in food, pharmaceutical, and chemical industries, offering both hygienic design and robust operation. The quick-clean mechanism enables rapid removal of captured contaminants: simply unlock the sealed access door and pull out the magnetic drawer to disengage the magnetic field, allowing ferrous materials to fall away for safe disposal. No tools are required, significantly reducing downtime during maintenance cycles.

This magnet integrates seamlessly into vertical or horizontal conveying lines with customizable pipe connection options. Its space-efficient design and food-grade components support compliance with USDA, FDA, and cGMP regulations, while improving product purity and protecting downstream equipment from costly damage.

Benefits of the Quick-Clean Inline Pneumatic Drawer Magnet From Magnetic Products, Inc

-

Rare-Earth Tubes for Superior Contaminant Capture

The unit features high-intensity rare-earth magnetic cartridges arranged in staggered rows to create a dense magnetic field across the product flow path. This configuration maximizes exposure and contact, ensuring reliable capture of fine, weakly magnetic, and loosely embedded ferrous particles. The magnetic strength provides effective separation in high-velocity pneumatic conveying applications, improving product purity and reducing the risk of metal-related equipment damage or recalls.

-

Tool-Free Quick-Clean Mechanism Reduces Maintenance

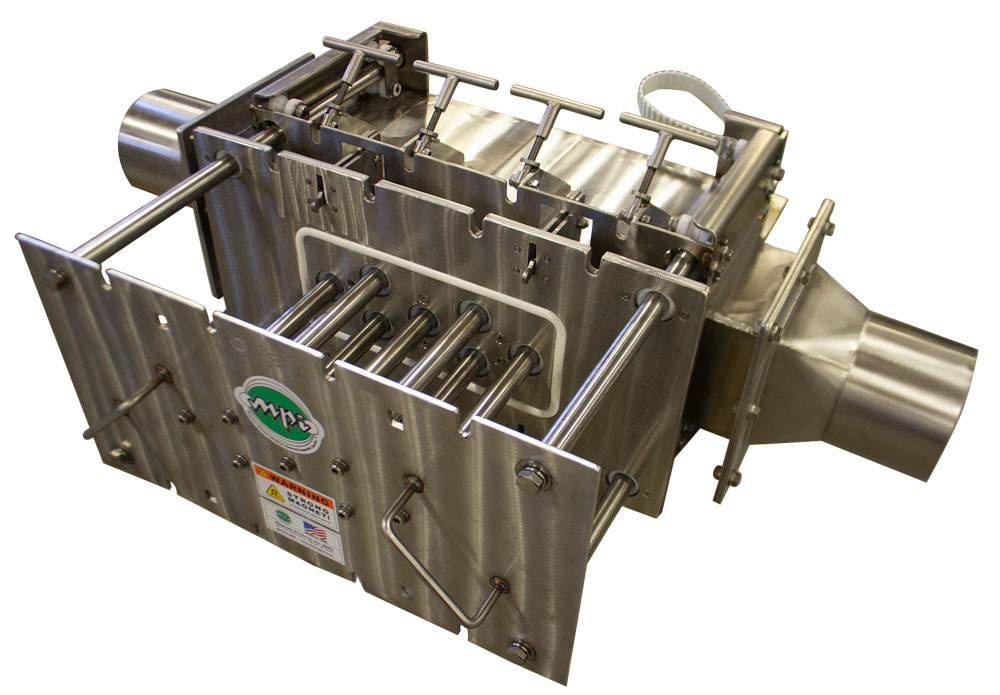

MPI’s quick-clean design incorporates a sliding drawer mechanism that allows operators to easily remove magnetic tubes from the process zone without disassembling the housing. When pulled out, the magnets disengage from the outer tube sleeves, causing the collected ferrous debris to fall cleanly into a disposal container. This streamlined, no-tools-needed process minimizes downtime and labor during routine cleaning, an essential advantage in high-volume operations with tight production schedules.

-

Hygienic, Dust-Tight Stainless-Steel Housing

Constructed from heavy-duty stainless steel (304 or 316 available), the housing is fully welded and sealed to prevent product leakage and contamination. Food-grade gaskets and finishes are available to meet sanitary requirements. The dust-tight construction maintains internal pressure integrity in pneumatic lines and helps preserve the cleanliness of the product zone, supporting compliance with food safety regulations and audit standards.

-

Seamless Inline Integration with Customizable Inlet/Outlet Sizes

The compact, cylindrical design is engineered for easy installation into horizontal or vertical pressurized conveying lines. MPI offers a range of flange and pipe connection types (including tri-clamp, ANSI flange, and custom fittings) to integrate with existing processing systems without requiring costly modifications. Its inline configuration minimizes space usage and pressure drop, preserving system efficiency.

-

Ideal for Pressurized Pneumatic Conveying Systems

The unit is specifically designed for pneumatic applications where materials are conveyed under pressure through closed tubing. Its reinforced housing and magnetic tube arrangement are optimized to withstand high flow velocities while maintaining effective separation. This makes it ideal for fine powders, granules, and bulk solids in food processing, plastics, pet food, and pharmaceuticals.

-

Designed to Meet Strict Sanitary and Quality Standards

sanitary welds, the magnet is suitable for use in applications requiring the highest levels of cleanliness and traceability. The quick-clean mechanism also reduces cross-contamination risk during changeovers, making it easier to meet HACCP, GMP, and other regulatory requirements for food and pharmaceutical manufacturing environments.

Quick-Clean Inline Pneumatic Drawer Magnet Product Details

The MPI Quick-Clean Inline Pneumatic Drawer Magnet is engineered to remove ferrous contaminants from dry, free-flowing materials conveyed under pressure through pneumatic systems. It operates within a sealed, inline housing and uses powerful magnetic separation and a user-friendly cleaning mechanism to maintain product integrity and process efficiency.

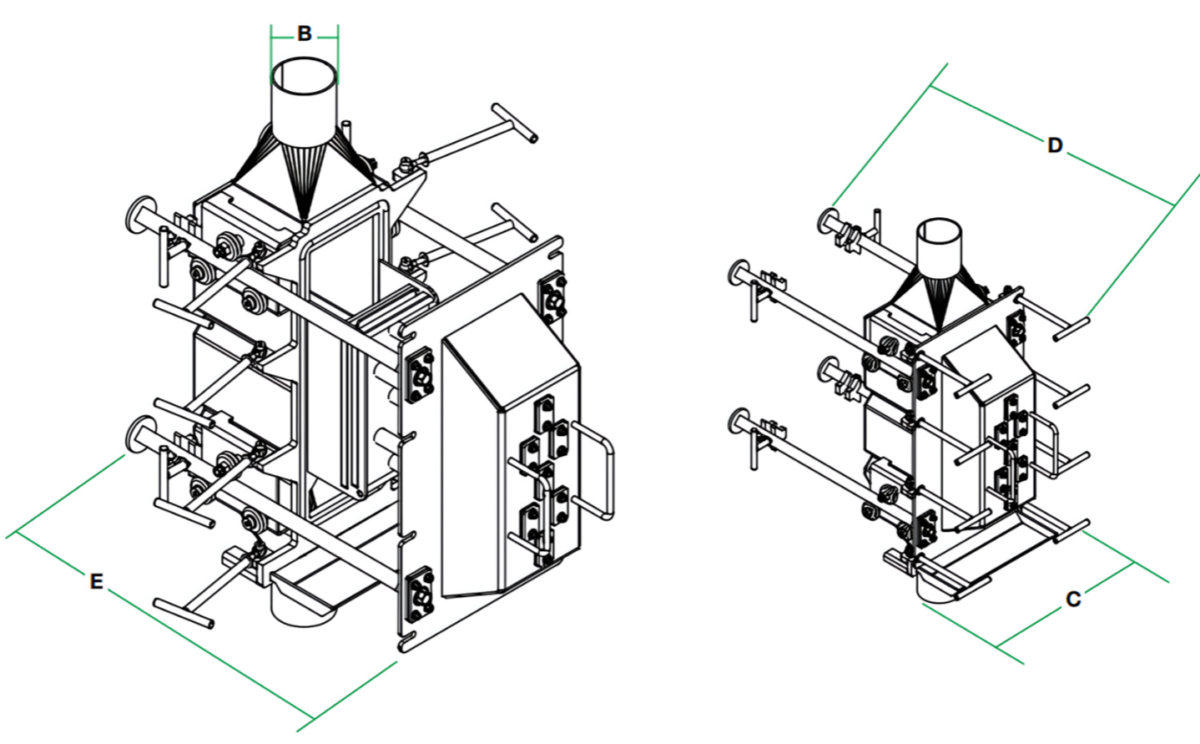

Installation & Positioning

The unit is installed directly into a pressurized pneumatic conveying line, horizontally or vertically, between source and destination points such as hoppers, sifters, or packaging equipment. The magnet housing features flanged or clamped pipe connections customized to match system specifications. Its compact, cylindrical design ensures minimal impact on system airflow and pressure drop.

Magnetic Separation Process

As material flows through the magnet housing:

-

It passes over high-strength rare-earth magnetic tubes arranged in a staggered, multi-row configuration.

-

These magnetic tubes create a dense magnetic field that attracts and retains ferrous contaminants, including fine particles, flakes, and tramp metal.

-

The staggered configuration ensures full exposure of the material stream to the magnetic field, maximizing contaminant capture.

This separation protects downstream equipment, such as extruders, mills, or packaging machines, from metal damage while improving final product quality.

Quick-Clean Operation

Unlike standard manual-clean models that require complete disassembly:

-

The Quick-Clean design allows the magnetic drawer assembly to slide out from the housing via a sealed, hinged access door, without tools.

-

When extended, the magnetic cartridges are mechanically separated from the outer stainless steel tube sleeves using a cam or linear guide system.

-

The magnetic field collapses within the material contact zone as the magnets are pulled out of alignment with the outer sleeves.

-

Captured metal contaminants fall freely from the tube surfaces into a designated collection area or disposal container.

This simple, tool-free mechanism allows operators to perform regular cleaning and maintenance in minutes, reducing downtime and improving operational efficiency.

Reassembly and Restart

After cleaning:

-

The drawer is pushed back into place.

-

The magnetic cartridges re-engage with the sleeves, re-establishing the magnetic field inside the flow path.

-

The access door is closed and sealed, and the system is immediately ready for continued operation.

This process ensures that metal separation remains continuous and effective without compromising pressure containment or product flow.

Quick-Clean Inline Pneumatic Drawer Magnet Specification Table

US Customary Units

| ILPDM MODEL # | (B) OPENING (IN.) | (C) WIDTH (IN.) | (D) OVERALL LENGTH (IN.) (DRAWER CLOSED) | (D) OVERALL LENGTH (IN.) (DRAWER OPEN) | HEIGHT (IN.) | NUMBER OF MAGNETIC TUBE ROWS | APPROX. WEIGHT (LBS) |

|---|---|---|---|---|---|---|---|

| ILPDM 3 | 3 | 17 | 33 | 34 | 20.6 | 7 | 77 |

| ILPDM 4 | 4 | 17 | 33 | 34 | N/A | 7 | 77 |

| ILPDM 5 | 5 | 17 | 33 | 34 | N/A | 7 | 77 |

Quick-Clean Inline Pneumatic Drawer Magnet Installations & Variations

Resin and Pellet Conveying Quick-Clean Inline Pneumatic Drawer Magnet Application in Plastics Manufacturing

Quick-Clean Inline Pneumatic Drawer Magnet Used in Nutraceuticals Powder Handling

Quick-Clean Inline Pneumatic Drawer Magnet Removing Contaminants from Flour, Starch, Baking Mixes, and Powdered Seasonings