Ensure Product Purity in Production Lines

Designed for applications requiring frequent cleaning with minimal downtime, the MPI Quick-Clean Plate Magnet features an efficient and user-friendly cleaning mechanism that streamlines contamination removal. The hinged or sliding assembly allows operators to quickly access the magnet surface, enabling fast and efficient debris removal without requiring extensive system shutdowns or disassembly. This design significantly reduces maintenance time and enhances overall process efficiency.

The Quick-Clean Plate Magnet simplifies routine cleaning by incorporating a smooth-release mechanism that lets operators wipe away or remove collected ferrous debris with minimal effort. By eliminating the need for manual scraping or prolonged handling, this system ensures that separation efficiency remains high while reducing labor demands. The Quick-Clean feature minimizes production interruptions, which is ideal for high-volume processing environments where contamination control is critical, helping facilities maintain consistent product quality and equipment protection. All MPI Plate Magnets are Intell-I-Mag® compatible.

Benefits of the Quick-Clean Plate Magnet With Housing (Inline Plate) From Magnetic Products, Inc

-

Superior Magnetic Contaminant Removal

Effectively captures and retains fine and large ferrous contaminants, including iron filings, screws, rust, and tramp metal, ensuring product purity. The high-intensity magnetic field extends deep into the material flow, providing consistent and reliable separation across bulk materials. Prevents metal contamination in food, pharmaceuticals, plastics, and other sensitive products, ensuring compliance with industry standards.

-

Fully Enclosed, Dust-Tight, Protective Housing

The sealed, sanitary housing prevents external dust, debris, and moisture from compromising material quality. It is designed for hygienic and dust-sensitive environments, making it ideal for food processing, chemical, and pharmaceutical applications. The housing also ensures uniform material flow, reducing the risk of product blockages or contamination from airborne particles.

-

Protects Processing Equipment & Reduces Downtime

Prevents tramp metal from reaching and damaging downstream equipment such as grinders, extruders, mills, and mixing systems. Reduces costly maintenance and unexpected breakdowns, improving overall equipment reliability and longevity. Minimizes production stoppages due to metal contamination, ensuring smooth operation and maximizing operational efficiency.

-

Flexible Cleaning Options for Reduced Maintenance

All MPI Plate Magnets are Intell-I-Mag® compatible. The easy-to-use Quick-Clean mechanism features hinged doors and secure latches that provide easy access for cleaning without requiring disassembly or complex maintenance. The Quick-Clean mechanism allows for fast debris removal in a single motion, reducing labor time and improving workflow efficiency.

-

Versatile Integration into Processing Lines

It is designed for seamless installation in chutes, hoppers, and pneumatic conveying systems and adapts to various material handling setups. It is available in multiple sizes and strengths, ensuring a custom fit based on product flow rates and contamination levels. It easily integrates into existing processing systems with minimal modifications, making it a cost-effective solution for contamination control.

-

Durable Stainless-Steel Construction for Long-Term Use

Constructed from high-grade stainless steel, providing exceptional resistance to wear, corrosion, and high-impact environments. Meets sanitary and food-safe standards (FDA, USDA, and GMP-compliant), ensuring safe operation in regulated industries. Built to withstand heavy-duty industrial applications, offering a long service life with minimal maintenance costs.

-

Ensures Compliance with Industry Regulations

Preventing metal contamination in sensitive products helps manufacturers meet strict HACCP, FDA, USDA, and GMP standards. It also reduces the risk of product recalls, rejections, and customer complaints due to contamination-related quality issues. Preventing metal contamination provides peace of mind by ensuring safe, contaminant-free production and protecting brand reputation and consumer safety.

-

Cost-Effective & Energy-Efficient Solution

It operates without a power supply, making it an energy-efficient, low-maintenance alternative to automated separation systems. It reduces ongoing operational costs by minimizing the need for expensive repairs, product waste, and downtime. It offers a high return on investment (ROI) by improving overall processing efficiency and reducing material contamination risks.

Quick-Clean Plate Magnet With Housing (Inline Plate) Product Details

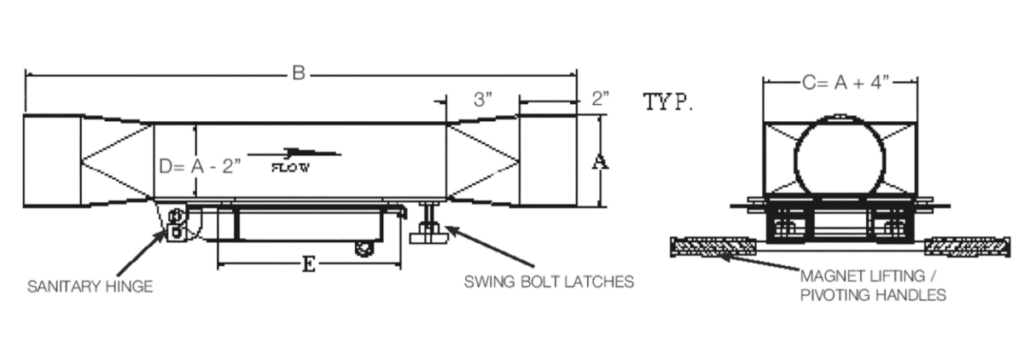

MPI’s Quick-Clean Plate Magnet with Housing (Inline Plate) is designed to provide enclosed magnetic protection for processing lines, ensuring efficient removal of ferrous contaminants from bulk materials. Its dust-tight housing prevents external contamination while allowing for seamless integration into gravity-fed, pneumatic, or mechanical conveying systems.

Enclosed Magnetic Protection

- As materials pass through the fully enclosed housing, the internal high-intensity plate magnet creates a strong magnetic field that attracts and holds ferrous contaminants such as metal shavings, nuts, bolts, and rust particles.

- The enclosed design ensures no external dust, debris, or moisture can compromise the purity of the material being processed.

- This feature is particularly beneficial in industries requiring sanitary conditions, such as food processing, pharmaceuticals, plastics, and chemicals.

Contaminant Collection Process

- As the product stream flows over the magnetic plate, tramp metal contaminants are captured and held securely on the magnet’s surface, preventing them from continuing downstream.

- The optimized magnetic circuit maximizes the holding power of the magnet, ensuring even small, weak, magnetic particles are effectively removed.

- The housing design ensures uniform product flow, minimizing material buildup and allowing for efficient separation of contaminants.

Quick-Clean Mechanism

- Quick-Clean models feature a wiping or sliding mechanism that allows operators to remove trapped contaminants in a single motion quickly.

- This significantly reduces cleaning time and minimizes production downtime, making it ideal for applications requiring frequent cleaning.

- The Quick-Clean feature ensures consistent separation efficiency while maintaining a high flow rate in processing lines.

Quick-Clean Plate Magnet With Housing (Inline Plate) Specification Table

US Customary Units

| ILPM MODEL # | (A) DIAMETER (IN.) (*MPI RECOMMENDED) | (B) OVERALL LENGTH (IN.) |

|---|---|---|

| ILPM-100 | 4* | 5 | 6 | 8 | 10 | 12 | 28.5 |

| ILPM-200 | 4* | 5* | 6 | 8 | 10 | 12 | 28.5 |

| ILPM-300 | 4 | 5* | 6* | 8 | 10 | 12 | 30.5 |

| ILPM-400 | 4 | 5* | 6* | 8* | 10 | 12 | 32.5 |

| ILPM-500 | 4 | 5 | 6* | 8* | 10* | 12 | 35.5 |

| ILPM-600 | 4 | 5 | 6 | 8* | 10* | 12* | 35.5 |

Quick-Clean Plate Magnet With Housing (Inline Plate) Installations & Variations

Quick-Clean Inline Plate Magnet Installed in Water Treatment Process

Quick-Clean Inline Plate Magnet with Intell-I-Mag® for Vertical Transfer of Bulk Dry Powder

Quick-Clean Inline Plate Magnet for Dairy Processing Application