Powerful Material Handling

MPI’s Magnetic Belt Conveyor is a powerful and efficient material handling solution engineered to securely move and elevate ferrous materials in a wide range of demanding industrial applications. By integrating high-strength permanent magnets beneath a durable, continuous belt, MPI ensures positive part control on horizontal, incline, or vertical planes—without slippage, jamming, or disruption. This conveyor is ideal for transporting steel or iron parts, chips, fasteners, stampings, and scrap where containment, orientation, and control are critical. Its rugged construction, customizable configurations, and low-maintenance design make it a preferred solution in metal stamping, machining, recycling, and metalworking environments.

Benefits of the Magnetic Belt Conveyor From Magnetic Products, Inc

-

Magnetic Positive Part Retention

Powerful permanent magnets under the belt hold ferrous parts in place—even on steep inclines or vertical lifts.

-

Sealed Design for Durability

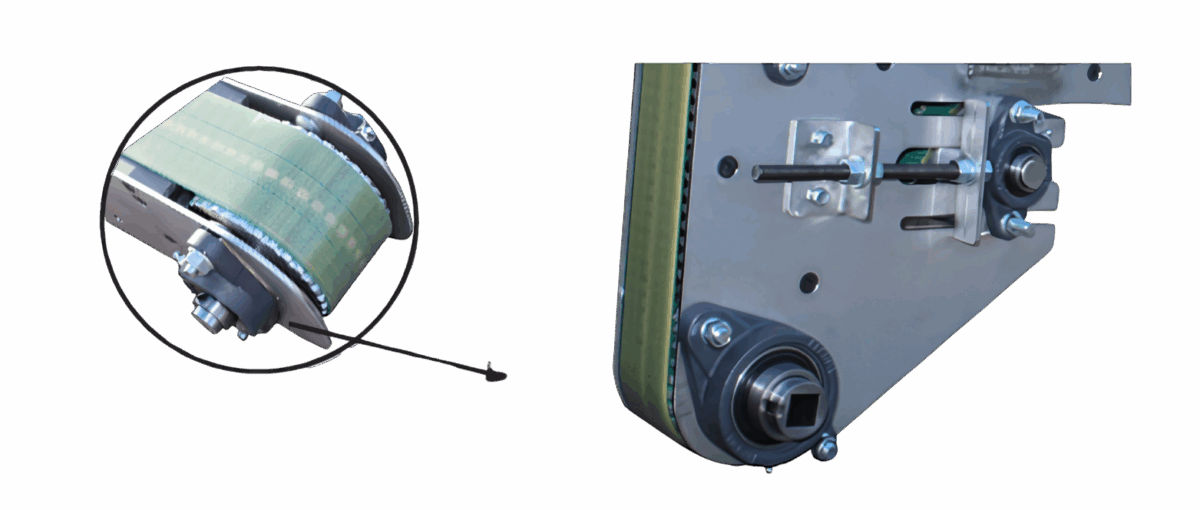

Magnets are enclosed in a sealed track beneath the belt, protecting them from contamination and reducing maintenance.

-

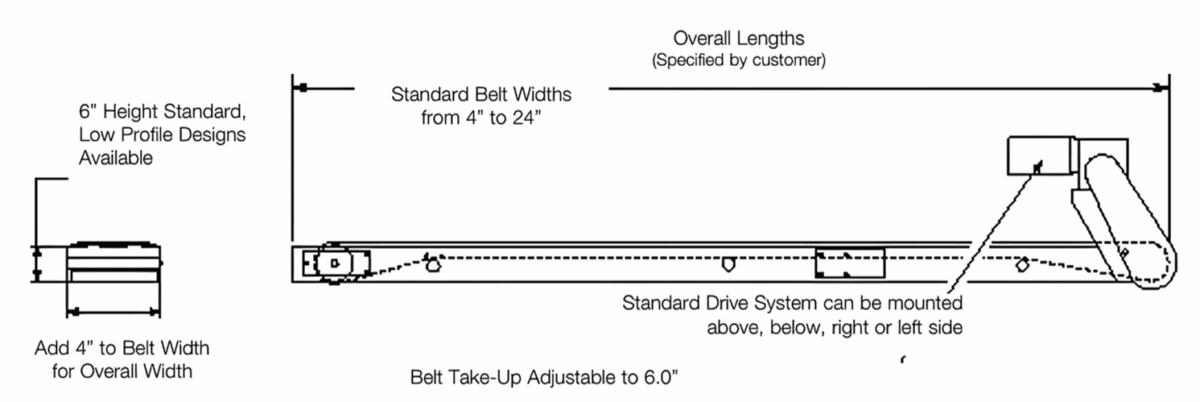

Customizable Belt Types and Widths

Belt material, cleats, and widths are tailored to specific applications and material types.

-

Heavy-Duty Frame and Construction

Built for continuous operation in harsh environments; resists impact, abrasion, and chemical exposure.

-

Ideal for Oily or Wet Parts

Effectively transports lubricated or slippery parts without slipping or misalignment.

-

Quiet, Low-Maintenance Operation

Fewer moving parts and a simple drive system reduce noise and extend service intervals.

-

Orientation and Containment Control

Maintaining consistent spacing and orientation of parts is critical for downstream automation or inspection.

-

Safe, Enclosed Magnetic Circuit

Prevents operator exposure to magnetic fields while delivering a consistent magnetic holding force.

Magnetic Belt Conveyor Product Details

MPI’s Magnetic Belt Conveyors provide effective control of ferrous objects on high-speed horizontal and inclined to vertical conveyor belts. A permanent or electromagnetic rail beneath the conveying belt surface attracts the ferrous objects to the belt. MBC conveyors have many design options and can also be supplied with other ancillary components such as feeders, hoppers, etc., to provide a complete material handling system. This magnetic attraction acts as a clamping force against the belt, causing the ferrous objects to move with the belt and be able to overcome any angle of inclination or decline. A wide range of styles is available for various belting designs, including fabric, tabletop, and stainless-steel mesh.

Loading Zone

Ferrous materials (e.g., metal parts or scrap) are introduced onto the conveyor belt.

Magnetic Engagement

Strong permanent magnets beneath the belt attract and hold ferrous items securely to the underside of the belt surface.

Conveyance

The continuous belt, driven by a motorized pulley or drive unit, moves the materials along the conveyor path, which can be horizontal, inclined, or vertical.

Incline or Vertical Transport

Magnetic force ensures parts remain secured to the belt during vertical or steep incline travel, preventing rollback or spillage.

Discharge

The magnetic field disengages as the belt rounds the drive pulley, and parts are released or guided off the belt.

Continuous Cycle

The belt loop and magnets reset, conveying the next batch of parts.

Magnetic Belt Conveyor Specification Table

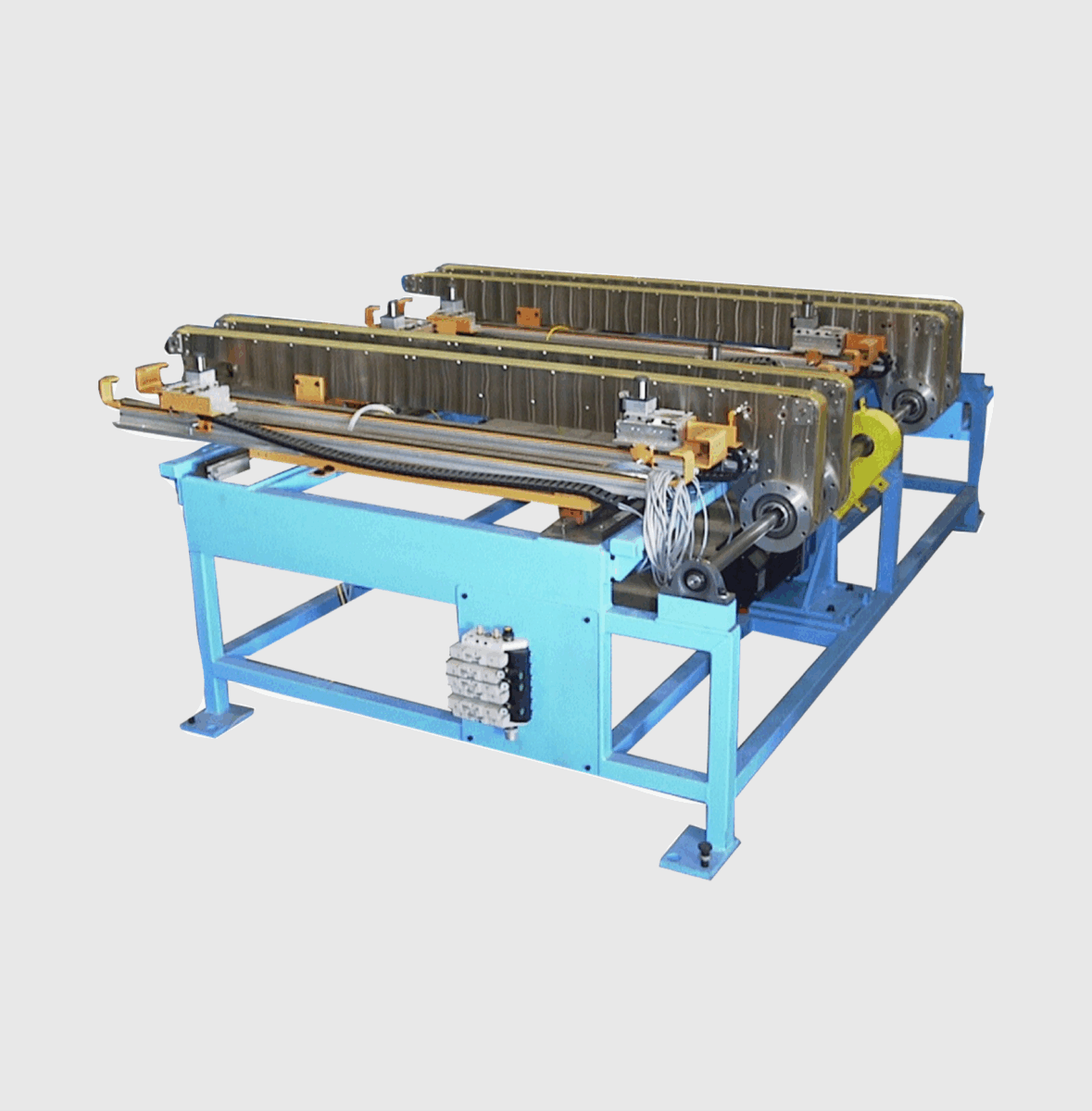

Magnetic Belt Conveyor Installations & Variations

Magnetic Belt Conveyor used in Parts Holding

Magnetic Belt Conveyor for Batch Processing

Magnetic Belt Conveyor in Canning Operation