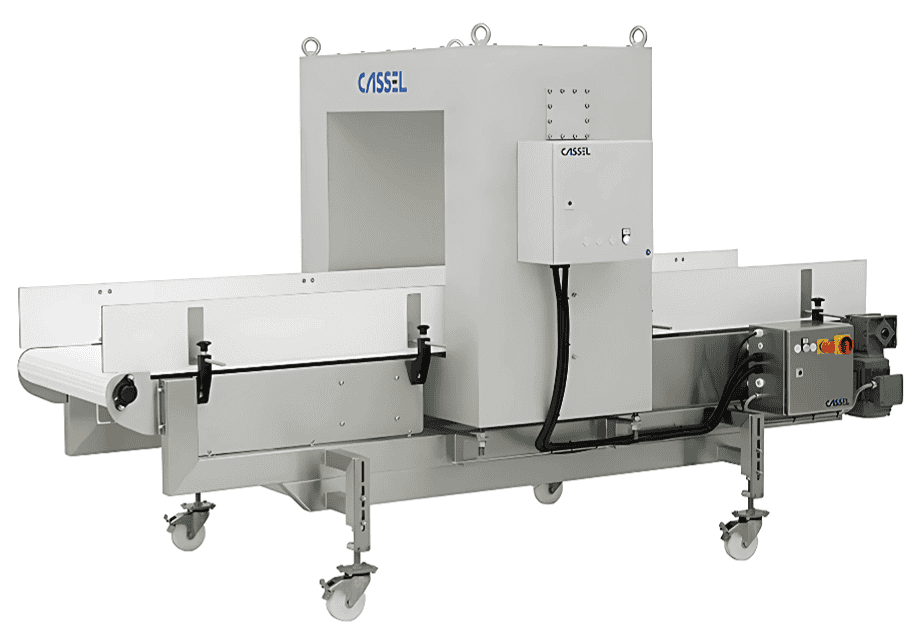

BIG Metal Detector Product Details

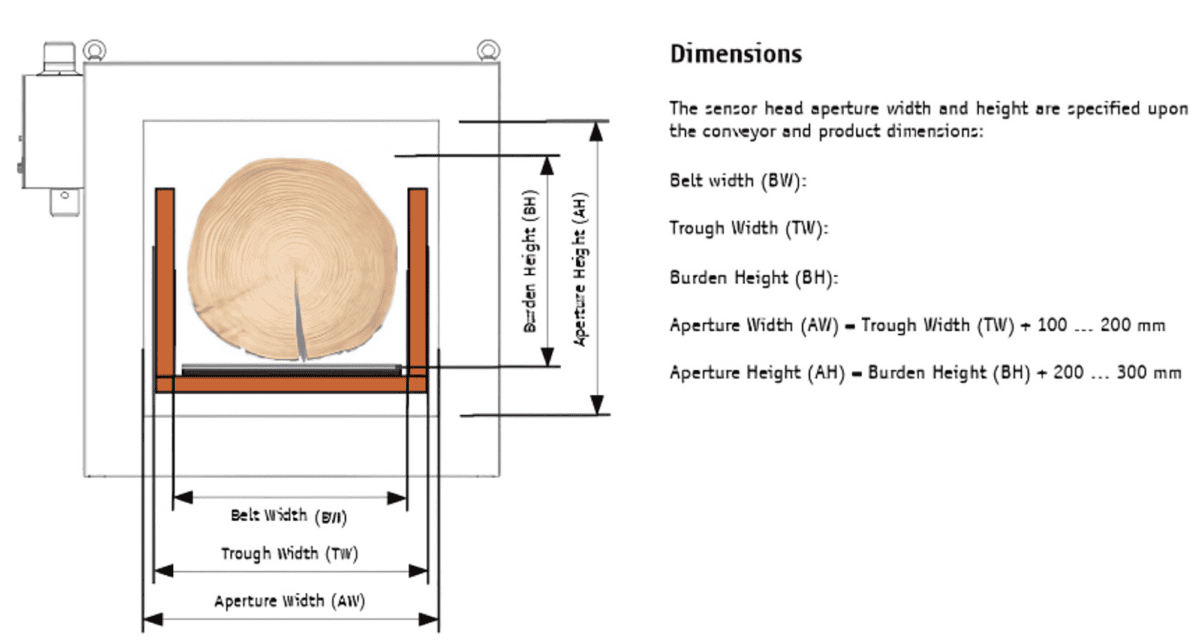

The SHARK® BIG Metal Detector operates as an inline detection system positioned around or above a conveyor carrying large, dense products. As materials pass through the oversized tunnel aperture, the system generates a balanced electromagnetic field that envelops the entire conveyor load.

When a piece of metal—ferrous, non-ferrous, or stainless steel—enters the detection zone, it disrupts this electromagnetic field. The disruption is instantly identified by the detector’s digital signal processor, which evaluates the disturbance and compares it to stored product compensation profiles.

Upon confirmation of contamination, the system triggers an alarm, stops the conveyor, or activates a reject signal (depending on the integrated control logic). Operators can then isolate the contaminated section or divert the load for further inspection or removal. The SHARK® BIG adapts to harsh environmental conditions and variable product characteristics to ensure consistent performance and minimal false rejects.

BIG Metal Detector Specification Table

US Customary Units

| MD-BIG COMPONENT FEATURE | METAL DETECTING FOR CONVEYOR INSTALLATIONS |

|---|---|

| Control Electronics | Digital signal processor, digital noise filter, digital balance control, digital frequency control with synthesizer, Power-Drive-Transmitter-Circuit, suitable with multi-frequency sensors, powerful graphics processing unit |

| Input Signals | 8 free configurable, 24 V D.C., e.g.: reject confirmation, air pressure monitor, conveyor belt control |

| Output Signals | 2 potential free: Metal and Error; 8 free configurable, 24 V D.C., e.g.: pusher magnetic valve, optic/acoustic alarm |

| Measuring Method | Inductive; multi-channel operation, balanced receiver coils |

| Metal Detection | Ferrous, non-ferrous (e.g. aluminum or copper) and stainless steel |

| Product Compensation | 120 storage spaces, compensation performed automatically, with Teach-Assistant |

| Protection Type | IP65; with Option LPW: IP66; with Option HPW: IP67 |

| Ambience | Standard: temp. -10°C to +40°C, rel. humidity 30 to 85% not condensing; Options: -40°C or +55°C |

| Product Temperature | -30°C to +60°C |

| Power Supply | Single-Phase 110 - 240 VAC, 50/60 Hz, fuse 10 A (slow), typ. power consumption 20W, max. 60W |

| Interfaces | RS232, USB, optional Ethernet |

| Maintenance | Maintenance-free, sensor calibrates itself automatically and continuously |

| Diagnosis | Integrated diagnostic software, automatic self-test |

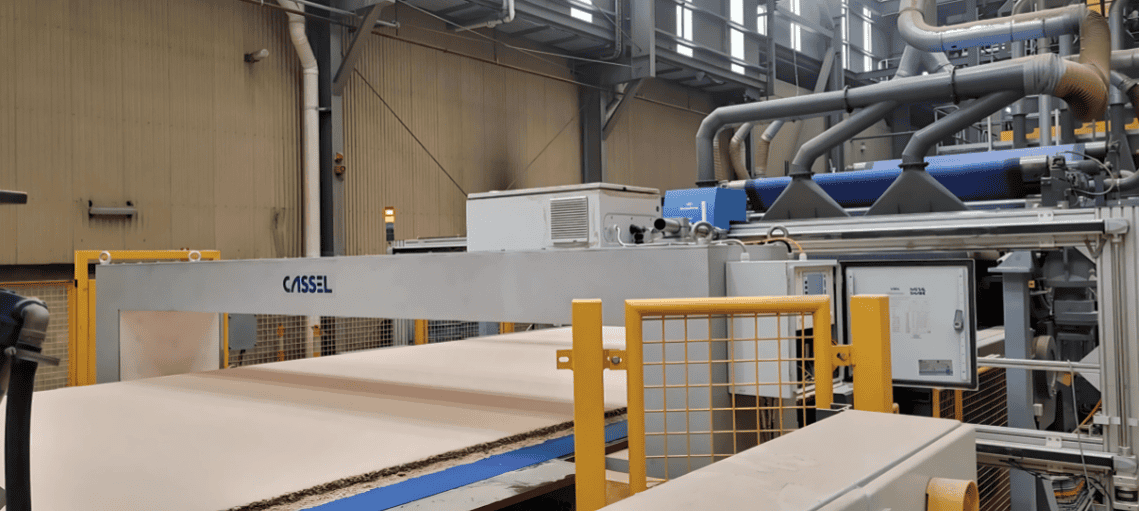

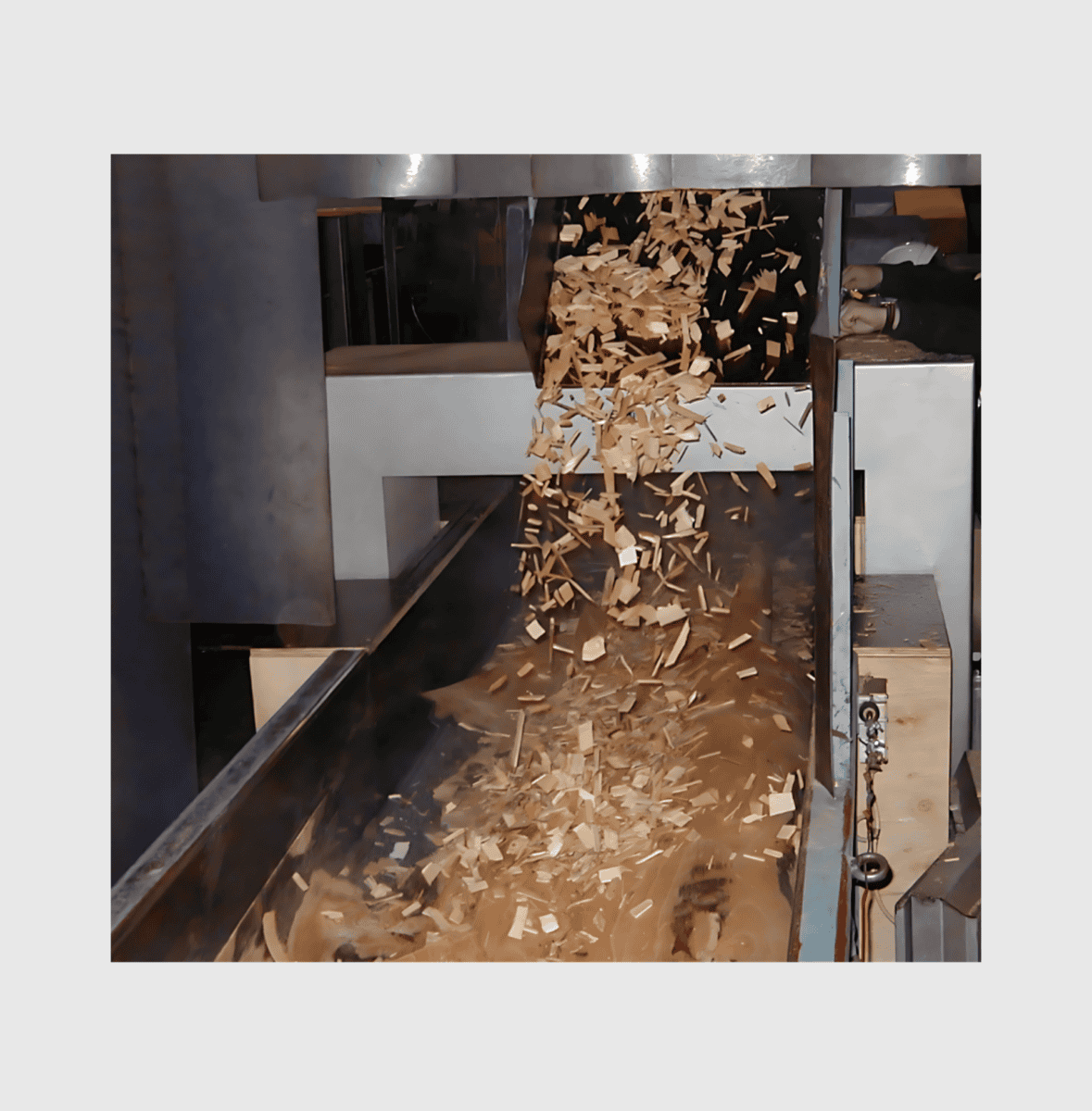

BIG Metal Detector Installations & Variations

BIG Detector Made for Abrasive Chemical Manufacturing Application

BIG Detector Made for Wood Chip and Paper Pulp Applications

MPI's Cassel BIG Detector Made for Ore and Aggregate Processing