MPI’s Metal Detector Controllers deliver precise, real-time control and monitoring of metal detection systems to ensure optimal sensitivity, reliability, and process integration. These controllers, designed for use with conveyor-based, pipeline, and drop-through metal detectors, feature intuitive interfaces, multi-frequency operation, customizable reject settings, and digital data logging. They enable rapid calibration, recipe management, and compliance tracking while minimizing downtime and false rejects. Whether installed in food, pharmaceutical, plastics, or recycling operations, MPI’s controllers enhance contaminant detection performance and system efficiency, giving operators complete control and confidence over product purity and regulatory compliance.

The MetalShark® 2 Controller is an advanced solution for metal particle inspection (MPI), featuring improved detection for ferrous, non-ferrous, and stainless-steel contaminants. It boasts a user-friendly interface and multi-frequency capabilities, utilizing innovative Four-Quadrant technology to enhance sensitivity with a full 360-degree detection area. Designed for challenging products like cheese and high-salt foods, it simplifies testing with vibrant screens and an integrated teaching assistant. The system includes strict password protection for authorized access, automatic data recording for compliance with HACCP, IFS, BRC, and GMP standards, and timestamps for metal detections and setting changes. Reports are easily downloadable to a Windows PC for long-term storage.

The METAL SHARK® BD can be used as a standalone unit or in combination with conveyor belts and chutes. It employs advanced 3D detection technology to accurately identify even the smallest magnetic and non-magnetic metal contaminants (such as iron, stainless steel, and aluminum) with high reliability, even in challenging environments. Its durable, sealed stainless steel housing is easy to clean, making it particularly suitable for the food industry. For the inspection of packaged goods, the MetalShark® BD Controller provides optimized performance, a compact design, and streamlined product changeover options specifically designed for conveyor-based systems.

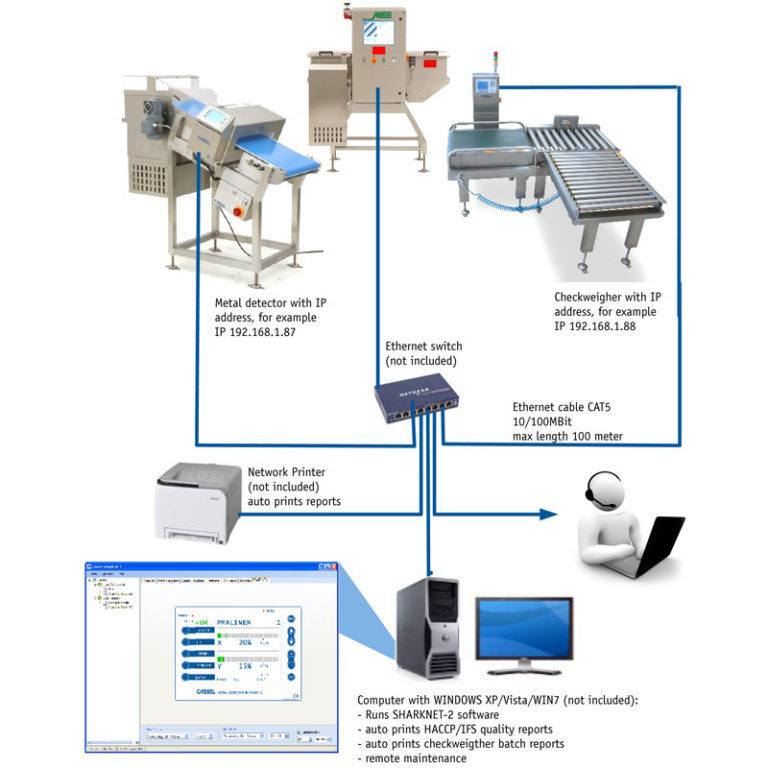

SharkNet® Software provides robust remote access, real-time monitoring, and centralized data logging to support HACCP and regulatory compliance. Ideal for use with metal detectors and checkweighers, it enhances operational visibility, simplifies validation tracking, and streamlines quality control. Available in two versions—SharkNet Light for remote maintenance and SharkNet for full-featured monitoring and management—it empowers operators to detect issues early, ensure validation completion, and generate actionable reports. SharkNet improves product quality by helping teams respond quickly to missed checks and maintain consistent inspection performance across food, pharma, plastics, and general manufacturing environments.

Compatibility Check - Metal Detector Controllers Comparison

Unique Benefits and Considerations

| Metal Detector Controller Type | Unique Benefits | Considerations |

|---|---|---|

| MetalShark® 2 Controller | High-sensitivity detection; Multi-frequency operation; Intuitive interface; Versatile across many detector types. | May require training for advanced configuration; More features than needed for simple applications. |

| MetalShark® BD Controller | Compact design for conveyor systems; Fast product changeover; Optimized for packaged goods. | Limited to belt/conveyor-based systems; Less flexible for non-packaged product lines. |

| SharkNet® Software | Enables remote monitoring and management; Supports HACCP compliance; Centralized data logging and validation tracking. | Requires network integration; Full version may involve additional cost and setup compared to SharkNet Light. |

For assistance in selecting the most suitable metal detection controller for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!