Flexible Design Solutions to Handle Any Application

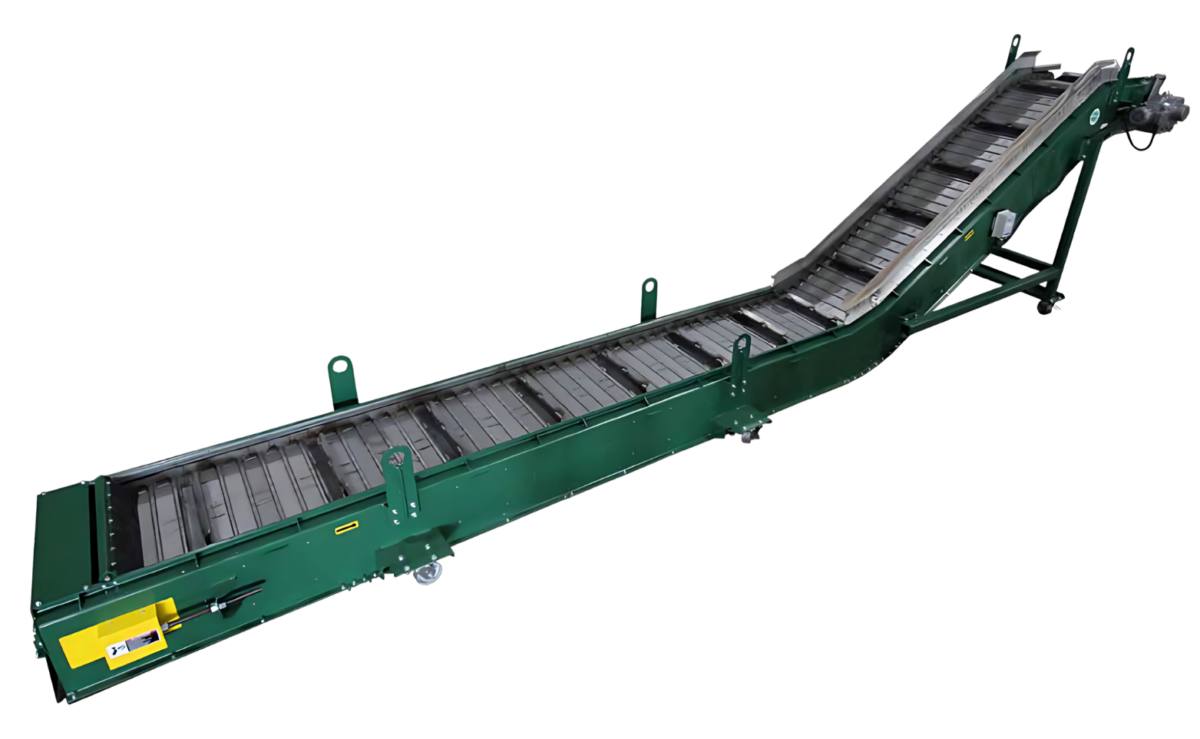

MPI’s Steel Hinge Belt Conveyor is a heavy-duty conveying solution that handles sharp, hot, or abrasive materials such as metal scrap, stamping slugs, die-cast parts, fasteners, forgings, and turnings. Built with interlocking steel belt segments mounted to robust side wings and cleats, this conveyor is engineered for rugged metalworking, machining, and recycling applications. The hinged steel belt resists damage from impact, heat, and cutting forces, making it ideal for harsh environments where rubber or fabric belts fail. In various configurations and discharge angles, MPI’s Steel Hinge Belt Conveyor streamlines material removal, improves operator safety, and boosts operational uptime.

Benefits of the Steel Hinge Belt Conveyor From Magnetic Products, Inc

-

All-Steel Construction

Handles hot, sharp, oily, or heavy materials that would damage traditional belts.

-

Impact-Resistant Hinge Belt Design

Each steel link absorbs shock loads and prevents belt puncture or tearing.

-

Oil and Coolant-Resistant Operation

Perfect for metal cutting, machining, and stamping lines where fluids are present.

-

Reinforced Side Wings and Cleats

Prevents spillage and guides scrap or parts up inclines.

-

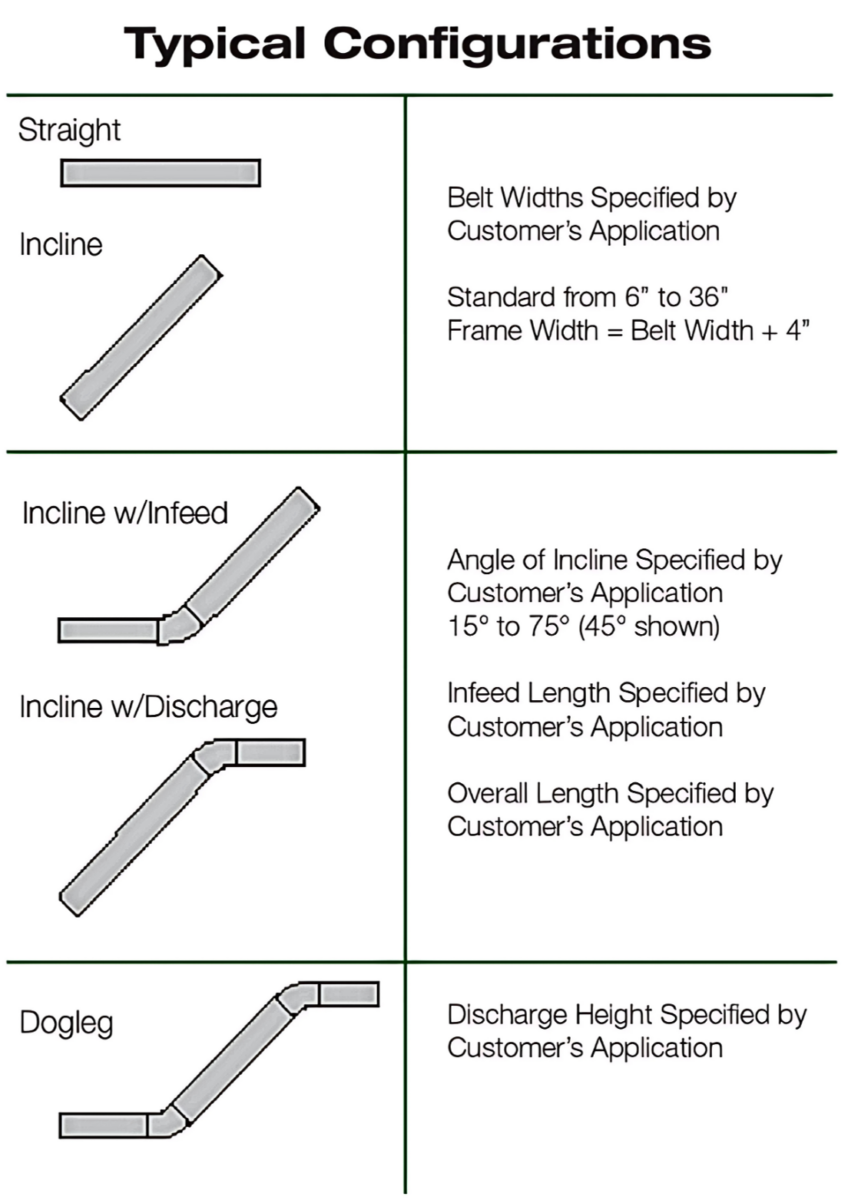

Custom Discharge Heights and Inclines

Optimized to fit bins, hoppers, furnaces, or downstream systems.

-

Low Maintenance and Long Lifespan

Minimal downtime compared to belt-driven alternatives in heavy-duty use.

-

Magnetic or Non-Magnetic Options

An integrated magnetic bed is available to capture and retain ferrous parts.

-

Hinged Access Covers and Clean-Out Areas

Streamlines service and maintenance in messy environments.

Steel Hinge Belt Conveyor Product Details

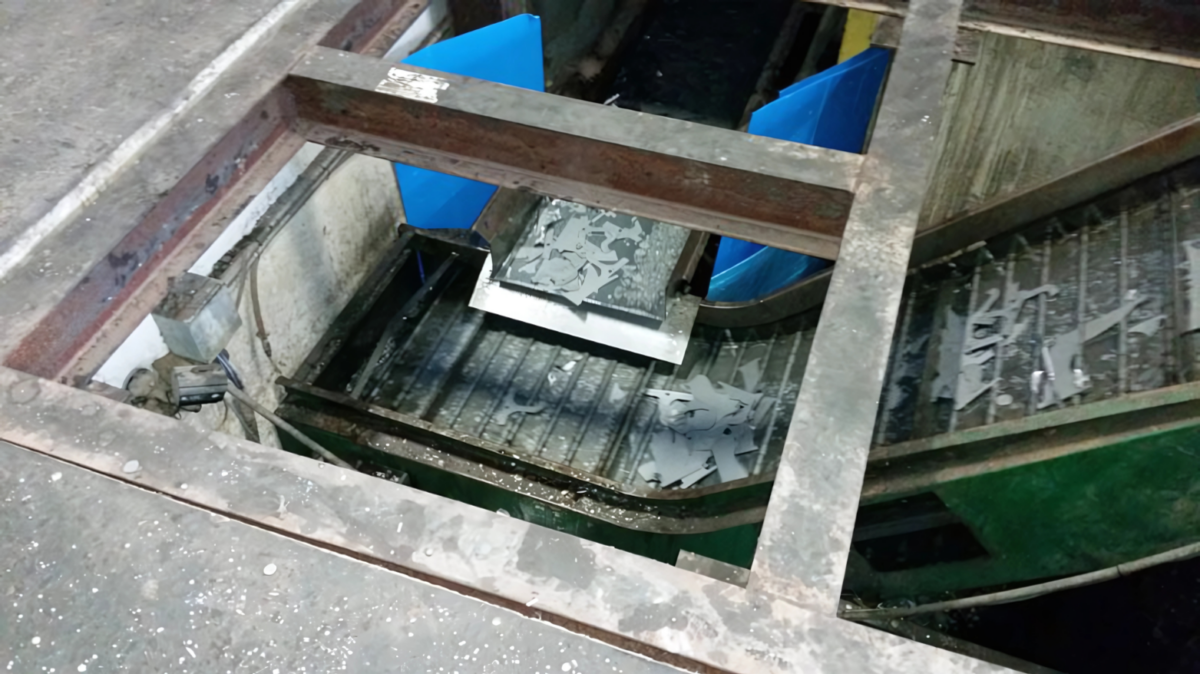

Scrap or Parts Enter Infeed Section

Material falls or is fed into the conveyor’s infeed zone, typically from a press, machine, or hopper.

Steel Hinge Belt Moves Material

A chain or sprocket system drives the interlocking steel plates, advancing the load.

Cleats Guide Material Up Incline

Cleats mounted on the belt push material upward on inclined configurations.

Coolant or Oil Drainage

Optional perforated plates allow fluid to drain into catch pans below the conveyor.

Discharge to Bin or Process

Material exits the conveyor at a designated height and is entered into a tote, bin, furnace, or crusher.

Repeat, Heavy-Duty Operation

Built to withstand 24/7 operation with minimal intervention.

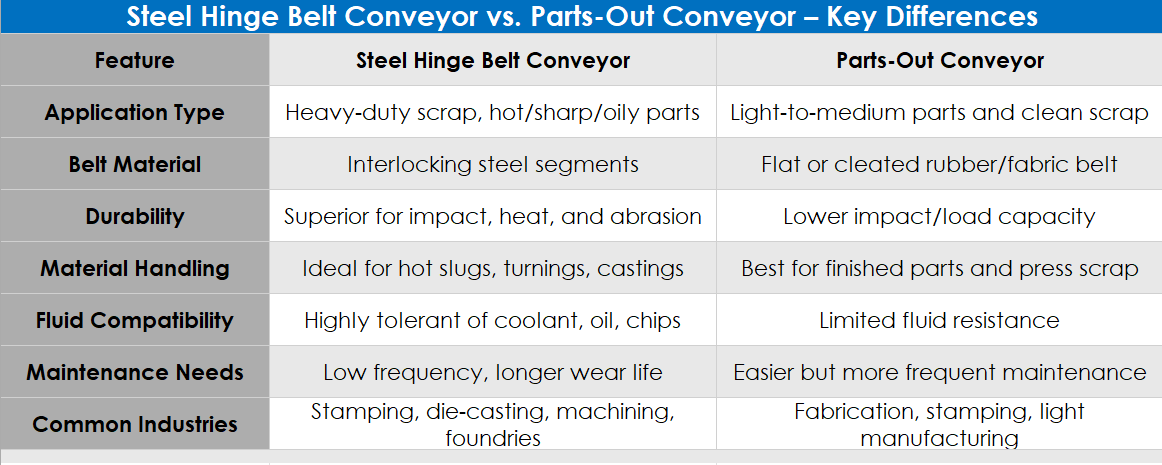

Difference Between Part-Out and Belted Conveyors

Steel Hinge Belt Conveyor Specification Table

US Customary Units

| MODEL FEATURE | STANDARD | HEAVY DUTY | EXTRA HEAVY CAPACITY |

|---|---|---|---|

| Pitch (in.) | 2.5 in. | 4 in. | 6 in. |

| Frame Depth (in.) | 8.5 in. | 15.25 in. | 23.25 in. |

| Frame Gauge ) | 12 | 10 | Channel |

| Drive Size | 6-Tooth | 6-Tooth | 6-Tooth |

Steel Hinge Belt Conveyor Installations & Variations

Steel Belt Conveyor Installed for Deep Draw Metal Processing Application

Steel Belt Conveyor Designed for HVAC Metal Part Manufacturing

Steel Belt Conveyor Specified for Tier-1 Automotive OEM