Simplified Reporting

SharkNet® is MPI’s advanced software platform for centralized monitoring, management, and documentation of metal detection and check weighing systems. Designed for production environments where regulatory compliance, traceability, and efficiency are essential, SharkNet® connects directly to MPI’s Metal Shark® controllers and checkweighers to provide real-time data visualization, system diagnostics, and automated report generation.

SharkNet® streamlines validation, audit preparedness, and quality assurance by logging events, archiving test results, and storing product profiles across connected inspection points. It supports both standalone workstations and networked installations with multi-device connectivity. SharkNet® is fully compatible with FDA 21 CFR Part 11 requirements and GFSI-based food safety programs such as HACCP, SQF, and BRCGS. With an intuitive interface and powerful tools, SharkNet® transforms inspection system management into a traceable, transparent, and paperless process.

Benefits of the Sharknet Software From Magnetic Products, Inc

-

Real-Time System Monitoring

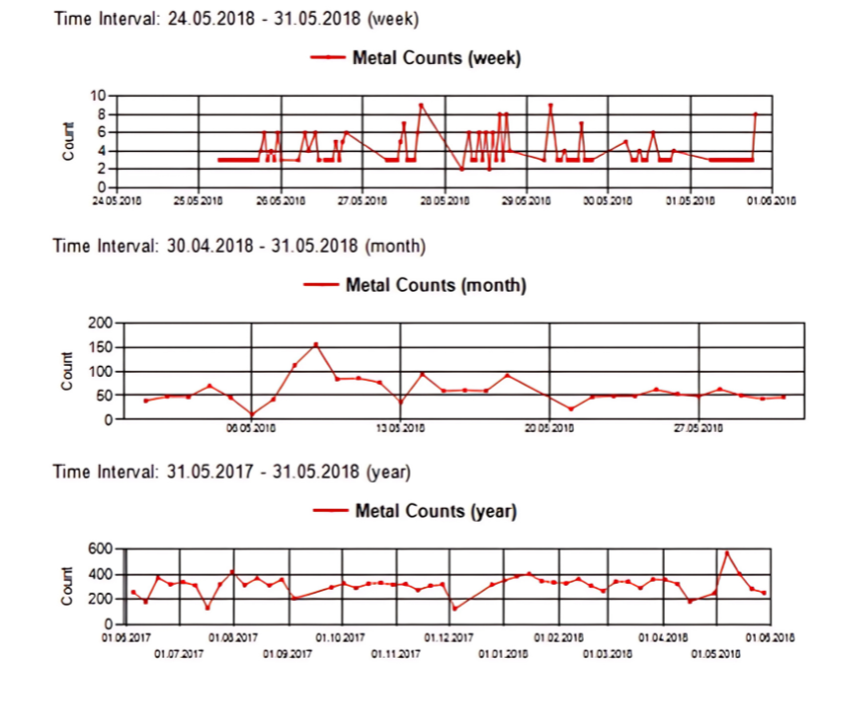

View live status of all connected metal detectors and checkweighers from a single interface, with updates on operating condition, detection events, alarms, and product flow.

-

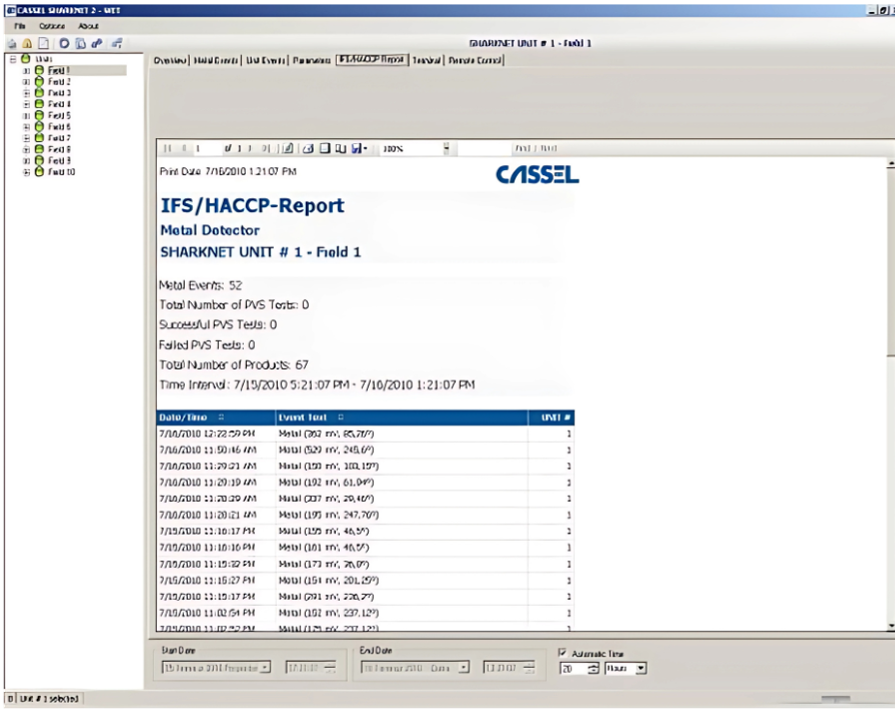

Automated Data Logging & Report Generation

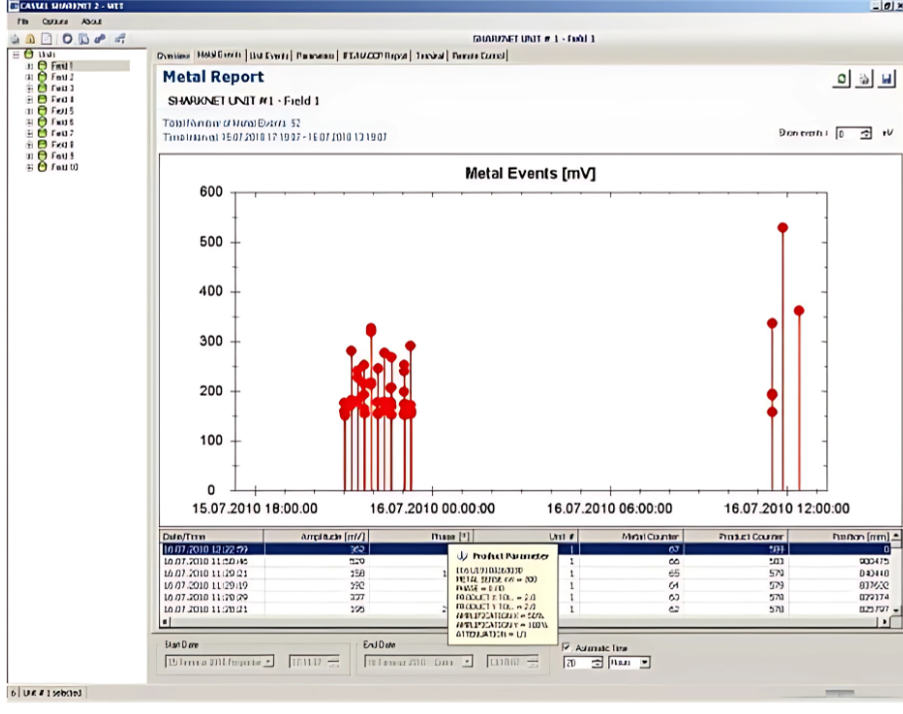

Records all system activity, including contaminant detections, validation checks, product changeovers, and operator interactions. Generates timestamped, exportable reports for audits and QA review.

-

Multi-Device & Multi-Line Connectivity

Connects to multiple MPI inspection devices simultaneously, enabling centralized control and performance comparison across production lines or facilities.

-

Validation & Compliance Tracking

Logs reject events, test results, and calibration actions with operator IDs to satisfy 21 CFR Part 11 electronic records requirements and support food safety audits.

-

User & Access Management

Offers secure user login, tiered access levels, and action tracking to protect critical settings and ensure accountability in regulated environments.

-

Product Memory & Changeover Tools

Centralizes product profile management for all connected systems—streamlining product changeovers, reducing setup time, and maintaining consistent sensitivity across shifts.

-

Alert & Notification System

Configurable notifications for error conditions, missed validation tests, or excessive rejects, ensuring prompt corrective actions before the non-conforming product is released.

-

Intuitive User Interface

Clean, graphical dashboard with drag-and-drop functionality, data export tools, and multi-language support for easy integration into global operations.

Sharknet Software Product Details

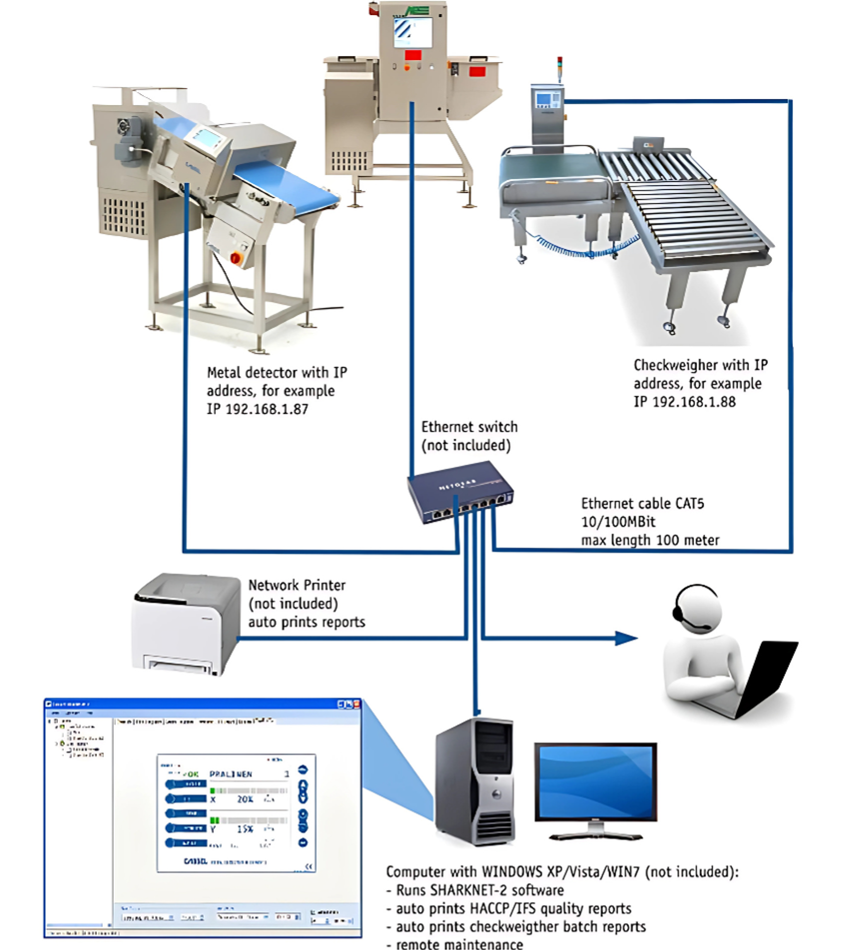

SharkNet® connects directly to MPI Metal Shark® metal detectors and checkweighers via a secure LAN or serial interface. Once connected, the software continuously gathers performance data from each system—including detection signals, reject activations, user inputs, test executions, and status changes.

This data is processed in real time and displayed through a unified dashboard, giving operators, QA teams, and supervisors a live view of each connected machine’s status. Events such as product changes, error messages, missed validations, or excessive rejects are recorded with time stamps and user credentials, creating a tamper-proof audit trail.

SharkNet® can also be configured to log product-specific settings, trigger alerts if validations are skipped, and generate compliance-ready reports on demand or on a schedule. Its centralized architecture allows one workstation or server to monitor multiple systems—on the same line or across facilities—delivering a single source of truth for inspection system performance.

Sharknet Software Specification Table

US Customary Units

| METAL SHARK CONTROLLER FEATURE | METAL SHARK 2 SOFTWARE CAPABILITY | SHARKNET SOFTWARE CONTROLLER CAPABILITY |

|---|---|---|

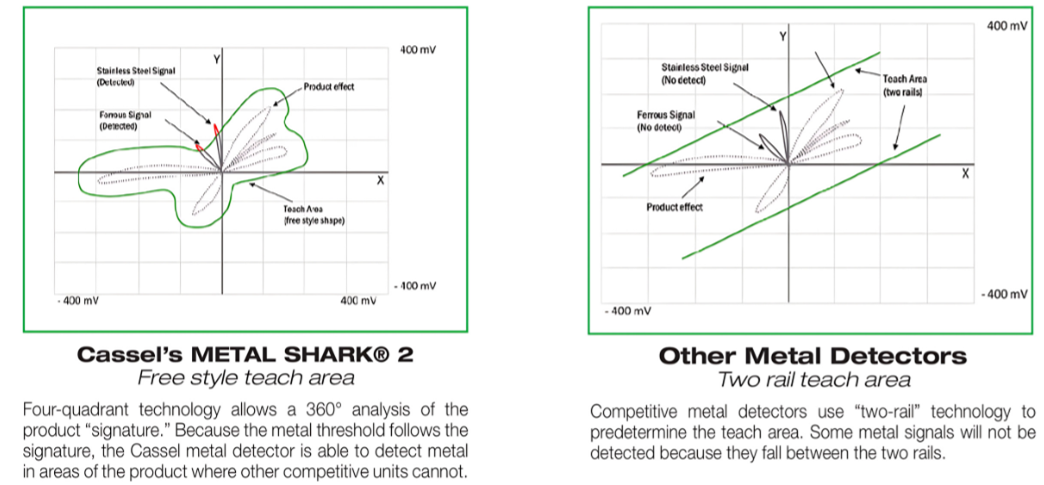

| Technology | 4-Quadrant Technology | Same as controller |

| Display | 5.4″ color screen | Computer LCD |

| Frequencies | 1, 2 or 4 | Same as controller |

| Sensitivity | Normal user achieves 90% of metal detectors maximum performance without expert optimization | Same as controller |

| Teach | 3 to 7 samples | Same as controller |

| Interface | Excellent digital filters | Same as controller |

| Outputs | (2) Potential Free, (8) Programmable | Same as controller |

| Inputs | (8) Programmable | Same as controller |

| Language | Global languages available | Same as controller |

| Memory | Integrated flash for 1000 events | Unlimited data logging capabilities in SQL database |

| Parameter Backup | No | To computer hard drive |

| Number of Custom Products | 120 | Same as controller |

| Temperature | Standard: temp. -10°C to +40°C, rel. humidity 30 to 85% not condensing; Options: -40°C or +55°C | Same as computer |

| Power Input | 85-264 V AC, 50/60 Hz, 1P, self selecting | Same as computer |

| Communication Interface | RS232, Ethernet and optional WLAN | Same as computer |

| Password Protection | 4 Levels | Software is password protected |

| Control of Multiple Systems | No | yes |

| Remote Maintenance | No | yes |

| Auto Print of Reports | Yes, any report to network printer | Any report to PDF or network printer |

| Performance Validation Software | Yes | yes |

Sharknet Software Installations & Variations

The SHARKNET® Software Networks All METAL SHARK® Metal Detector Machines with One Windows Computer

The SHARKNET® Software Benchmark for Performance, User-Friendliness and Ease of Documentation

The SHARKNET® Software Digital Frequency Control Utilizes Synthesizer Technology to Generate a Constant and Stable Frequency