Maintenance Free Design

MPI’s Gravity Feed Metal Detector detects and removes ferrous, non-ferrous, and stainless-steel contaminants from free-falling, dry bulk materials such as powders, grains, spices, and plastic pellets. This high-sensitivity system is installed in vertical pipelines or chutes and provides reliable inspection for gravity-fed product streams before blending, packaging, or further processing. It is engineered for hygienic environments and features a stainless-steel body, compact design, and a quick response reject mechanism. Ideal for food, pharmaceutical, chemical, and plastics industries, this system helps ensure product purity, protect downstream equipment, and maintain compliance with quality and safety standards.

Benefits of the Gravity Feed Metal Detector From Magnetic Products, Inc

-

High-Sensitivity Multi-Frequency Detection

Detects ferrous, non-ferrous, and stainless-steel contaminants—even the smallest particles—using advanced digital signal processing and multi-frequency technology.

-

Sanitary, Stainless-Steel Construction

Built with smooth, crevice-free surfaces for easy cleaning and compliance with FDA, USDA, and other food and pharma safety standards.

-

Fast-Acting Auto-Reject System

Integrated reject flap or diverter valve rapidly removes contaminated product from the flow stream, reducing waste and minimizing downtime.

-

Compact, Space-Saving Design

Designed for easy integration into gravity-fed production lines with limited vertical clearance, without sacrificing detection performance.

-

Tool-Free Maintenance and Cleaning

Quick-access components allow operators to perform maintenance, cleaning, and calibration without specialized tools, improving line uptime.

-

User-Friendly Interface with Digital Controls

Features an intuitive touchscreen controller with product memory, auto-learn functions, and customizable reject timing for accurate operation.

-

Flexible Product Adaptability

Capable of handling a wide range of dry, free-flowing bulk materials, from granular plastics to flour and powdered spices.

-

Full Integration with Quality Control Systems

Supports data logging, reject monitoring, and optional connectivity with remote QA systems for traceability and compliance audits.

Gravity Feed Metal Detector Product Details

The MPI Gravity Feed Metal Detector is designed for installation in vertical pipes or chutes where dry bulk materials move freely under the force of gravity. As the material descends through the detector's sensing coil, it traverses a highly sensitive electromagnetic field produced by the metal detection unit.

The system continuously evaluates the electromagnetic reaction of the material. Upon detecting any metal, the control unit instantly triggers a high-speed reject mechanism—commonly a pneumatically actuated flap, diverter, or separation valve—that diverts the contaminated material into a designated reject bin.

Simultaneously, the uncontaminated product continues downstream without interruption. The system's software records detection events, enabling operators to monitor rejects and implement corrective measures as necessary. The detector can be easily calibrated to suit various products, bulk densities, and flow rates to reduce false rejects and ensure optimal detection precision.

Intended for free-falling powders and bulk products, the Metal Detector operates within a gravity feed pipeline. As the bulk material passes through the detector, any metallic contaminants, whether magnetic or non-magnetic, are swiftly isolated by the reject flap, effectively removing them from the product stream.

The METAL SHARK® Gravity Feed (GF) Metal Detectors, available in both standard and compact configurations, are used in gravity feed pipelines for detecting unwanted metal contaminants in continuously flowing granules or powders like sugar, flour, cornmeal, and spices.

All product contact components meet FDA food-grade quality standards. As the bulk material flows through the metal detector, the reject flaps efficiently separate even the smallest metallic contaminants from the product stream.

Designed to be maintenance-free and constructed with high-quality materials, these detectors ensure reliable performance in the most demanding industrial environments. Pipe diameters range from 1/2″ to 24″, with ATEX Zone 21 and 22 versions also available.

The Metal Detector GF is widely utilized for products including:

-

Powdered milk

-

Sugar

-

Cereal

-

Proteins

-

Spices

-

Granules

Enclosed in 100% stainless steel housing, the Metal Detector GF is specifically engineered for the food industry.

Available digital controller: METAL SHARK® 2A.

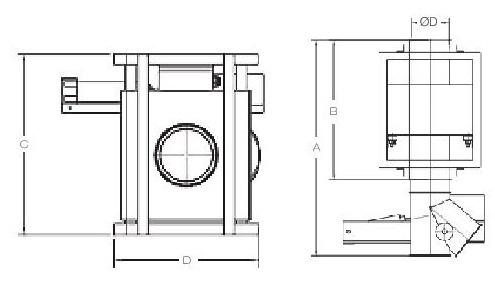

Gravity Feed Metal Detector Specification Table

US Customary Units

| MODEL # | DIA. FLOW OPENING (OD) (IN.) | (A) OVERALL HEIGHT (IN.) | (B) MD HEIGHT (IN.) | (C) MD WIDTH (IN.) | (D) MD DEPTH (IN.) | TYPICAL MATERIAL FLOW RATE (FT³/HOUR) | FE SENSITIVITY (IN.) | AI SENSITIVITY (IN.) | SS SENSITIVITY (IN.) |

|---|---|---|---|---|---|---|---|---|---|

| GF0100 | 4 | 23.6 | 15.8 | 17.7 | 12.5 | 700 | 0.02 | 0.028 | 0.031 |

| GF0120 | 5 | 28.4 | 19.3 | 17.7 | 13.3 | 1000 | 0.028 | 0.035 | 0.039 |

| GF0150 | 6 | 33.5 | 21.7 | 19.8 | 15.8 | 1500 | 0.031 | 0.043 | 0.051 |

| GF0200 | 8 | 47.2 | 31.1 | 24.2 | 20 | 2600 | 0.047 | 0.063 | 0.071 |

| GF0250 | 10 | 54.9 | 36.8 | 31.5 | 26 | 4000 | 0.059 | 0.079 | 0.091 |

| GF0300 | 12 | 63.2 | 43.3 | 37 | 31.5 | 5800 | 0.075 | 0.094 | 0.118 |

| GF0350 | 14 | 76.2 | 49.8 | 40.2 | 34.7 | 7900 | 0.087 | 0.106 | 0.13 |

| GF0400 | 16 | 82.7 | 53.2 | 42.9 | 37.4 | 10300 | 0.094 | 0.114 | 0.142 |

Gravity Feed Metal Detector Installations & Variations

Gravity Feed Metal Detector for High-Speed Dry Bulk Material Flow Inspection

Custom Moveable Gravity Feed Metal Detector Mounded on a Free-Standing Cart

MPI Gravity Feed Metal Detector for Vertical Pipe Installation