Ideal for Vertical Applications in Tight Spaces

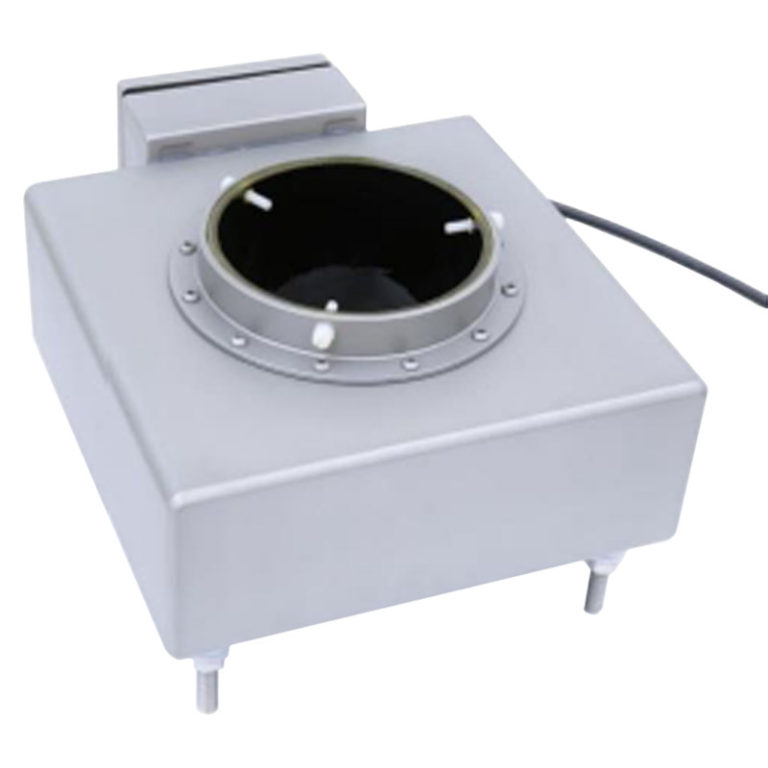

The MPI Throat Gravity Metal Detector is designed to integrate into vertical form-fill-seal (VFFS) packaging machines, providing high-performance metal detection in free-falling product streams. Positioned directly above the forming tube, it inspects bulk solids, powders, or granules such as snacks, spices, cereals, and granulated ingredients just before packaging. With its compact, hygienic design and high-sensitivity detection, the Throat Metal Detector is an ideal critical control point (CCP) for food, pharmaceutical, and chemical industries. It helps protect brand reputation, meet regulatory compliance, and ensure contaminant-free packaged products—all while maintaining high production speeds and minimal space requirements

-

Integrated Vertical Packaging Mounting

Compact, low-profile housing designed to fit directly above the form-fill-seal (FFS) forming tube for space-efficient, inline inspection.

-

High-Sensitivity Multi-Frequency Detection

Detects ferrous, non-ferrous, and stainless-steel contaminants with pinpoint accuracy, even in high-speed applications with small product particles.

-

Fast Reject Response Time

Works with high-speed reject systems or bag indexing to ensure that only the affected product is removed with minimal waste and no disruption to production flow.

-

Hygienic Stainless-Steel Construction

Durable, food-grade housing with smooth surfaces and optional IP65 or IP69K washdown protection to meet strict sanitation standards.

-

Tool-Free Maintenance & Calibration

Quick access to components and intuitive auto-learn functions reduces setup time and simplify cleaning, testing, and product changeover.

-

Versatile Product Handling

It supports a wide variety of free-falling, dry bulk products—from snacks and seeds to powders and granules—with consistent performance across densities.

-

User-Friendly Digital Interface

Features an intuitive touchscreen controller with product memory, sensitivity adjustment, real-time status alerts, and reject event logging.

-

Compliance with HACCP & GFSI Standards

Ideal for use as a Critical Control Point in certified food safety programs, with options for validation ports, data logging, and performance verification.

Throat Metal Detector Product Details

The MPI Throat Gravity Metal Detector is installed between the product hopper and the forming tube of a vertical form-fill-seal (VFFS) packaging machine. As the free-falling product moves by gravity through the metal detector’s detection coil, it passes through a precisely tuned electromagnetic field.

If a contaminant—such as ferrous, non-ferrous, or stainless steel—is present in the product flow, it disturbs the electromagnetic field and triggers the detection system. The integrated controller instantly processes the signal and either sends a reject command or flags the contaminated product via the VFFS system’s controls (such as pausing bag sealing or rejecting a filled bag downstream).

This configuration ensures that metal contamination is detected at the last possible point before the product is sealed, allowing the system to prevent contaminated packages from entering distribution while minimizing product waste and maintaining high packaging speeds.

Throat Metal Detector Applications

Throat Metal Detectors are Ideal for Form Fill Seal Co-Packers

Throat Metal Detectors are Used in the Manufacturing and Packaging of Snack Foods

Throat Detectors Well-Suited for Products Packaged in Bags or Pouches, Whether Dry, Liquid, or Granular