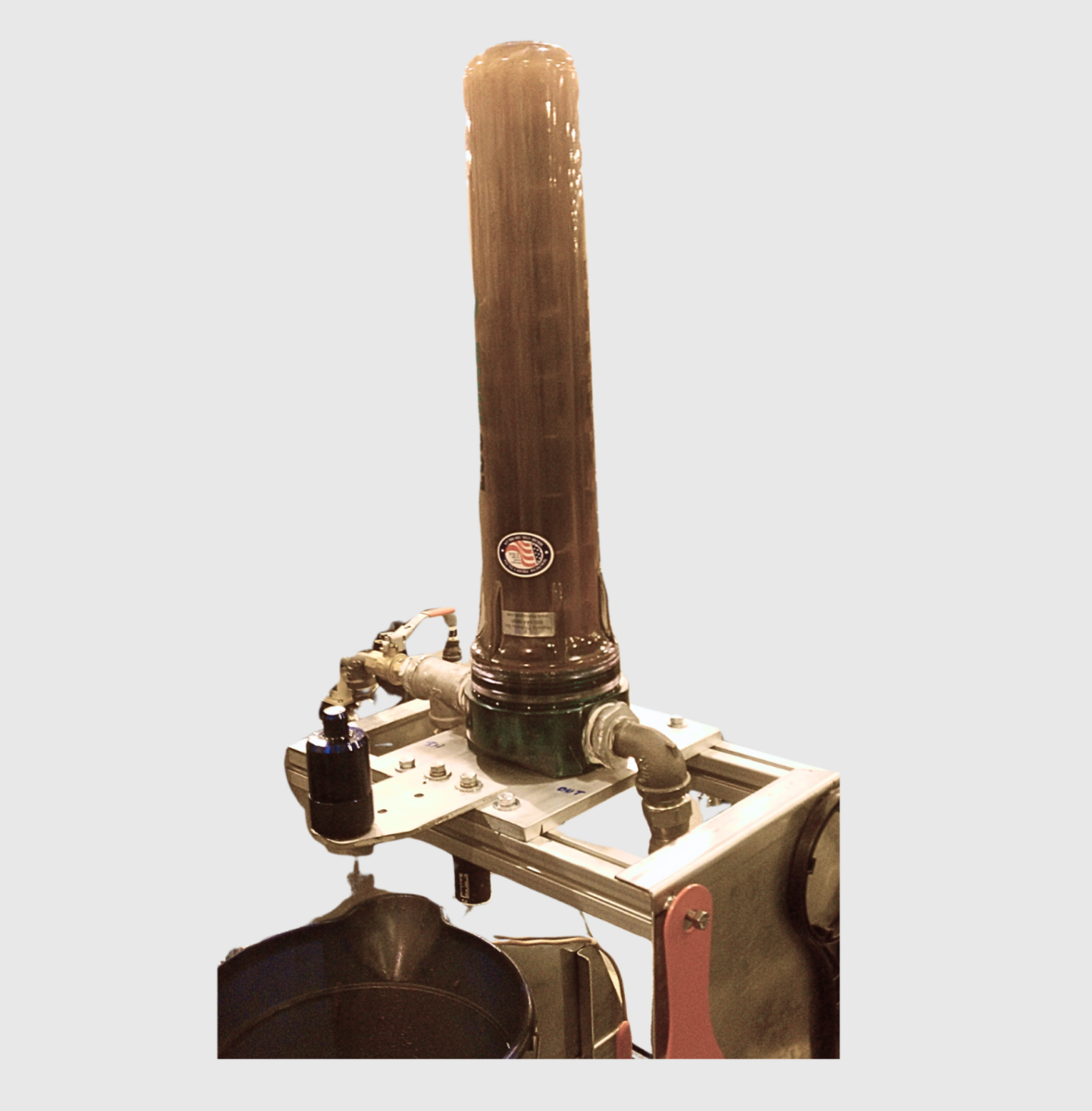

Easily Integrated Into Shop Fluid Lines

The MPI Eco-Mag® Magnetic Filter is an advanced filtration solution designed to remove ferrous and paramagnetic contaminants from industrial fluids. Its efficient design enhances fluid lifespan, product quality, and reduces maintenance costs while allowing easy integration into various systems. Capable of achieving sub-micron filtration with minimal pressure loss, it utilizes Rare Earth Magnetic materials to create powerful magnetic flux fields, allowing it to capture magnetic particles of any size, including sub-micron levels. This system serves as an exceptional pre-filter, extending fluid life, improving surface finishes, and minimizing machinery wear without incurring ongoing costs associated with consumables, making it a superior alternative to traditional filtration methods that are sensitive to particle size.

Benefits of the Eco-Mag® From Magnetic Products, Inc

-

Compact & Efficient Design

Easily fits into tight spaces without compromising filtration performance.

-

Superior Contaminant Removal

Captures ferrous and paramagnetic particles, even at sub-micron levels, ensuring cleaner fluids.

-

Enhanced Product Quality

Delivers superior surface finishes and precision by reducing contaminants in lubricants, coolants, and industrial fluids.

-

Cost Savings & Sustainability

Eliminates the need for disposable filters, lowering fluid disposal costs and reducing environmental impact.

-

Minimal Pressure Drop

Provides high filtration efficiency without restricting fluid flow, making it ideal for machine tool oils and coolants.

-

Durable & Low-Maintenance

Uses powerful Rare Earth Magnetic technology to remove metal debris, eliminating recurring filter replacement costs.

Eco-Mag® Product Details

The Eco-Mag® Magnetic Filter seamlessly integrates into shop fluid lines, providing highly effective ferrous and paramagnetic contaminant removal from lubricants, coolants, and other industrial fluids. Utilizing advanced Rare Earth Magnetic Technology, the Eco-Mag®® ensures cleaner fluids, longer equipment life, and reduced maintenance costs.

Step-by-Step Filtration Process

Fluid Entry & Flow

- Industrial fluids are pumped through the Eco-Mag® unit, where they are directed over a high-intensity magnetic core.

- This fluid may contain steel turnings, chips, and fine swarf particles from machining or manufacturing processes.

Magnetic Contaminant Capture

- As the fluid passes over the powerful Rare Earth Magnetic material, ferrous and paramagnetic contaminants are attracted and securely retained on the magnetic core.

- Unlike conventional filters, which rely on pore size and can clog, the Eco-Mag®® is not particle-size sensitive—capturing everything from larger metal chips to sub-micron ferrous debris.

Clean Fluid Output

- The contaminant-free fluid continues through the system, enhancing machine performance, reducing wear, and improving product quality.

- Since the Eco-Mag® operates with minimal pressure drop, it does not disrupt fluid flow, making it an efficient solution for high-performance industrial environments.

Quick & Easy Cleaning

- Once the magnetic core reaches full contamination capacity, cleaning is simple and takes less than 30 seconds.

- The supplied cleaning tool easily removes all collected metallic particles, leaving you with only dry, solid metal waste that can be conveniently disposed of or recycled.

- No messy cartridges or consumable filters—drastically reducing maintenance time and cost.

Eco-Mag® Advantages Over Conventional Filtration

- Sub-Micron Filtration – Captures even the smallest ferrous particles.

- Eco-Friendly & Cost-Efficient – Eliminates disposable filters, reducing operational waste.

- Minimal Downtime – Fast cleaning process keeps machines running efficiently.

- Longer Fluid Life – Reduces fluid contamination, extending its usability.

- Protects Machinery – Lowers wear on components, reducing maintenance costs.

Eco-Mag® Specification Table

US Customary Units

| ECOMAG® MODEL # | OVERALL LENGTH (IN) | DIAMETER (IN.) | CONNECTION NPT (IN.) | MAX. PSI PRESSURE | FLOW RATE (GAL./HR.) | MAX. TEMP (F.) |

|---|---|---|---|---|---|---|

| ECO5 /1.0 | 7.5 | 3.7 | 1 | 174 | 18 | 41-122 |

| ECO10 /1.0 | 12.4 | 4 | 1 | 174 | 26 | 41-122 |

| ECO20 /1.5 | 23.9 | 4 | 1.5 | 174 | 39 | 41-122 |

Eco-Mag® Installations & Variations

EcoMag® Magnetic Filtration for Industrial Lubricant

EcoMag® Magnetic Filtration Installed in Grinding Application

EcoMag® Magnetic Filtration Installed in Metal Honing Process