Reliable Ferrous Metal Separation in Pneumatic Conveying Lines

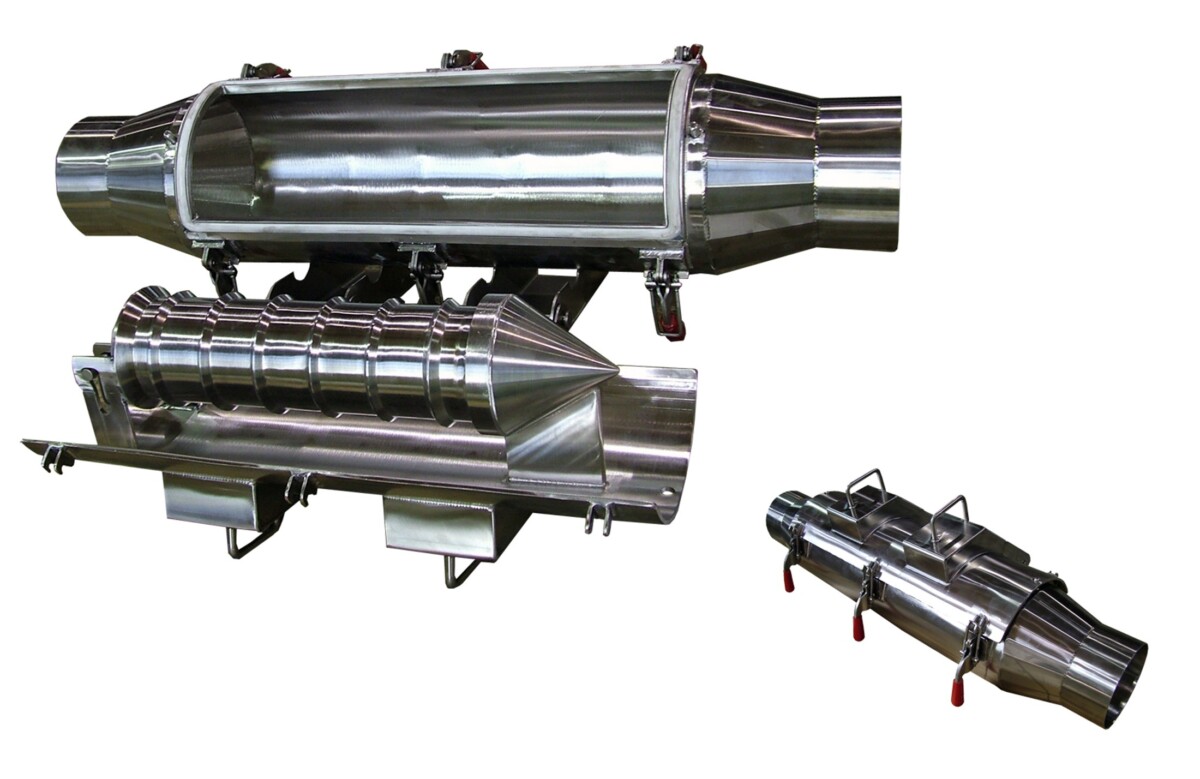

The MPI Pneumatic Line Magnet (PLM) is a powerful, compact inline magnetic separator engineered to remove ferrous contaminants from dry, free-flowing materials under pressure. Designed for vertical or horizontal installations in dilute-phase pneumatic transfer systems, the PLM uses a high-strength rare-earth plate magnet to capture tramp iron and fine ferrous particles without impeding product flow.

Its angled, aerodynamic design and obstruction-free opening ensure low-pressure drop and smooth conveyance of materials such as flour, grains, powders, and plastic pellets. With no internal moving parts and minimal maintenance requirements, the PLM provides long-lasting, cost-effective protection for downstream processing equipment while ensuring food, pharmaceutical, and industrial quality standards compliance.

Available in manual-clean and quick-clean configurations, the PLM is ideal for processors seeking to improve product purity, reduce downtime, and safeguard machinery in space-constrained or high-speed pneumatic lines.

Benefits of the Pneumatic Line Magnet From Magnetic Products, Inc

-

Powerful Plate Magnet with Rare-Earth Strength

Utilizes a high-intensity rare-earth magnetic plate mounted at an optimal angle to intercept the product stream and effectively attract and retain ferrous particles, even in high-velocity environments.

-

Streamlined Aerodynamic Design

The low-profile, obstruction-free housing ensures minimal pressure drop and turbulence during conveying. Its internal flow deflector guides material evenly across the magnetic plate, preserving product integrity.

-

Durable Stainless-Steel Construction

Built with all-welded 304 or 316 stainless steel for long service life, corrosion resistance, and sanitary compliance. Suitable for demanding food, chemical, plastic, and pharmaceutical environments.

-

Manual or Quick-Clean Options

Available with a basic manual-clean version (requiring removal of the magnet plate for cleaning) or a quick-clean hinged door design that allows tool-free removal of ferrous debris for faster maintenance.

-

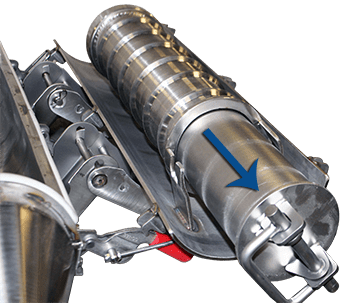

Tool-Free Access Door (Quick-Clean Model)

The quick-clean configuration includes a hinged access door with secure latches, allowing fast cleaning and reinstallation of the magnetic plate without disrupting the conveying system.

-

Compact, Inline Integration

It is designed for easy installation into vertical or horizontal pipelines, especially where space is limited. Standard pipe connections and a compact footprint simplify retrofits or new system integration.

-

No Moving Parts

The PLM does not have motors, actuators, or pneumatic systems, making it ideal for operations seeking low-maintenance, mechanical simplicity with high reliability and uptime.

-

Regulatory and Sanitary Compliance Ready

Polished internal surfaces and food-grade gaskets are available for compliance with USDA, FDA, and cGMP standards. Ideal for applications requiring hygienic design and easy inspection.

Pneumatic Line Magnet Product Details

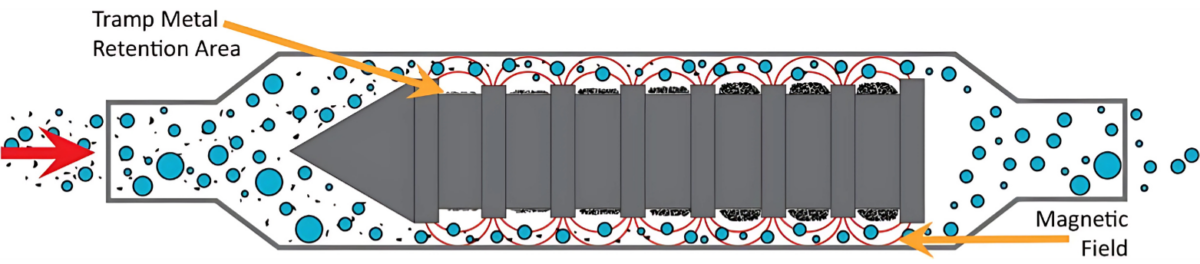

The Pneumatic Line Magnet (PLM) introduces a powerful magnetic plate into the product stream within a pressurized conveying line. It is designed for inline use in dilute-phase pneumatic systems, where dry bulk materials are transported at high velocity under air pressure.

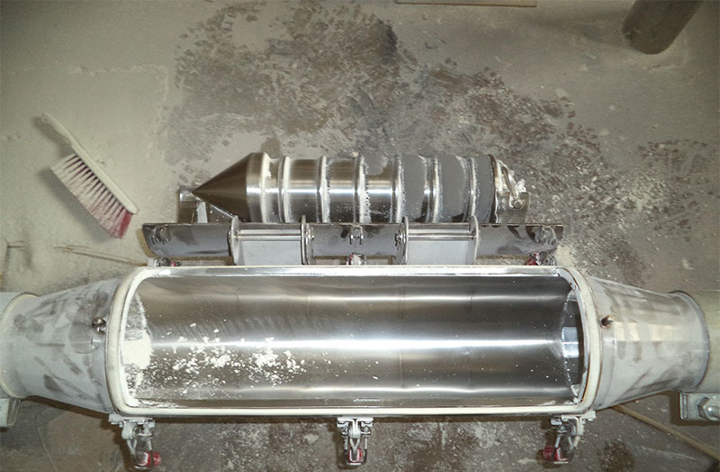

Inline Installation

The PLM is installed directly into a straight section of conveying pipe—either vertical or horizontal—using flanged or clamp connections. It becomes part of the sealed pneumatic system, maintaining airflow integrity.

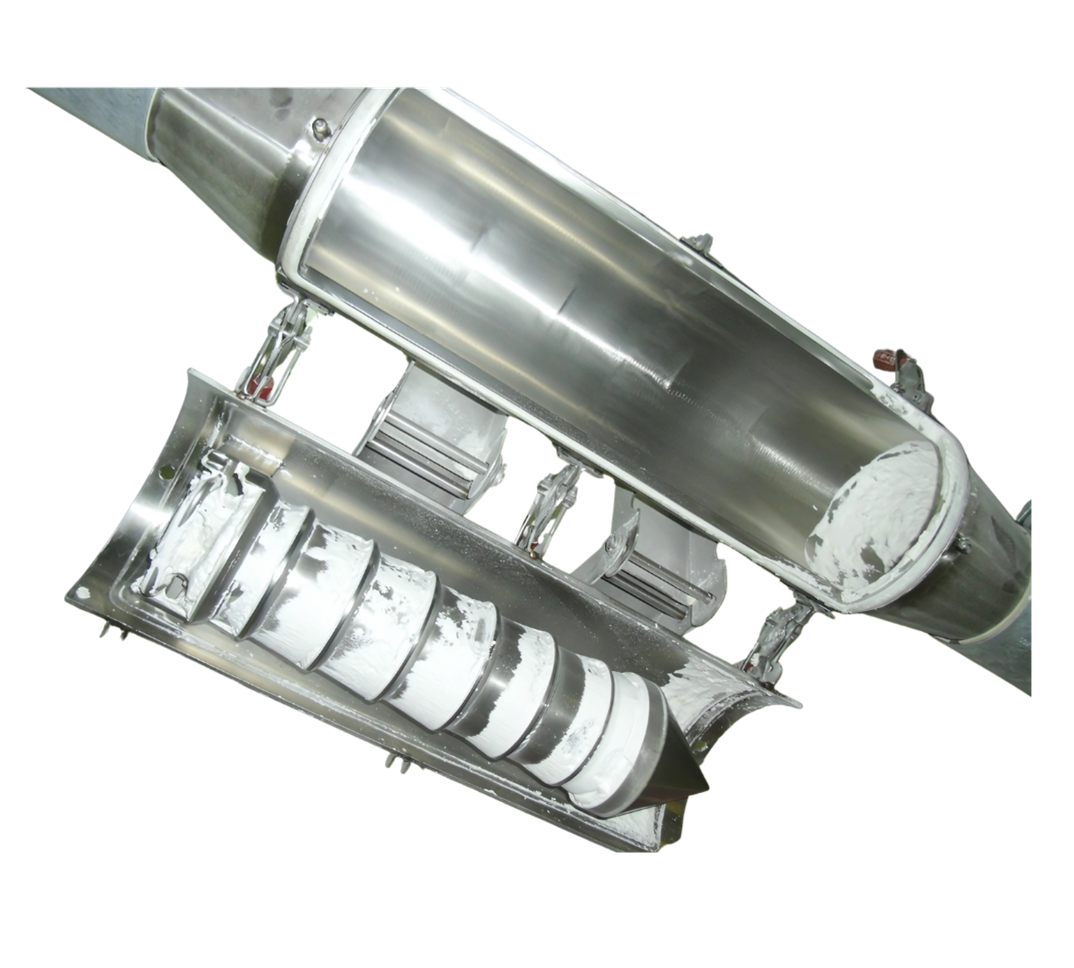

Product Entry and Deflection

As the material enters the PLM, an internal flow diverter gently redirects the material flow toward the magnetic plate. This ensures that even fast-moving particles come into proximity with the magnet.

Ferrous Contaminant Capture

The rare-earth magnetic plate attracts and holds tramp iron, fine metal dust, and weakly magnetic particles against its surface. Thus, the clean product continues unobstructed through the pipeline.

Cleaning and Maintenance

- In the manual-clean version, the conveying line is stopped, and the magnetic plate is removed from the housing to manually wipe off the metal debris.

- In the quick-clean version, operators open the hinged access door, slide out the plate, and safely clean it without tools, significantly reducing downtime.

Reassembly

After cleaning, the magnetic plate is reinserted, and the unit is resealed. Conveying resumes immediately with full magnetic protection restored.

This straightforward, non-mechanical operation delivers dependable ferrous separation with minimal impact on system pressure or flow rate.

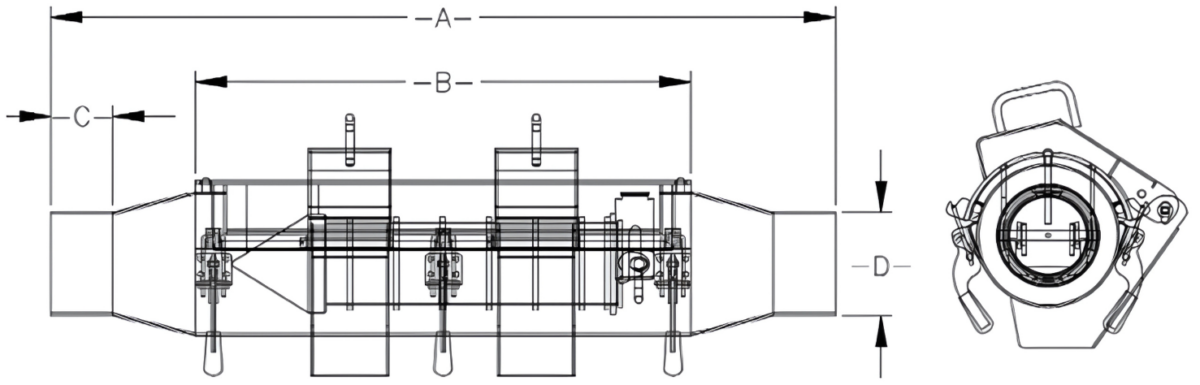

Pneumatic Line Magnet Specification Table

US Customary Units

| MODEL # | (A) OVERALL LENGTH (IN.) | (B) DOOR LENGTH (IN.) | (C) TUBE LENGTH (IN.) | (D) TUBE DIAMETER (IN.) | APPROX. WEIGHT (LBS) |

|---|---|---|---|---|---|

| PLM 3 | 38 | 24 | 3 | 3 | 85 |

| PLM 4 | 38 | 24 | 3 | 4 | 88 |

| PLM 5 | 38 | 24 | 3 | 5 | 92 |

| PLM 6 | 38 | 24 | 3 | 6 | 98 |

| PLM 7 | 38 | 24 | 3 | 7 | 137 |

| PLM 8 | 38 | 24 | 3 | 8 | 170 |

Pneumatic Line Magnet Installations & Variations

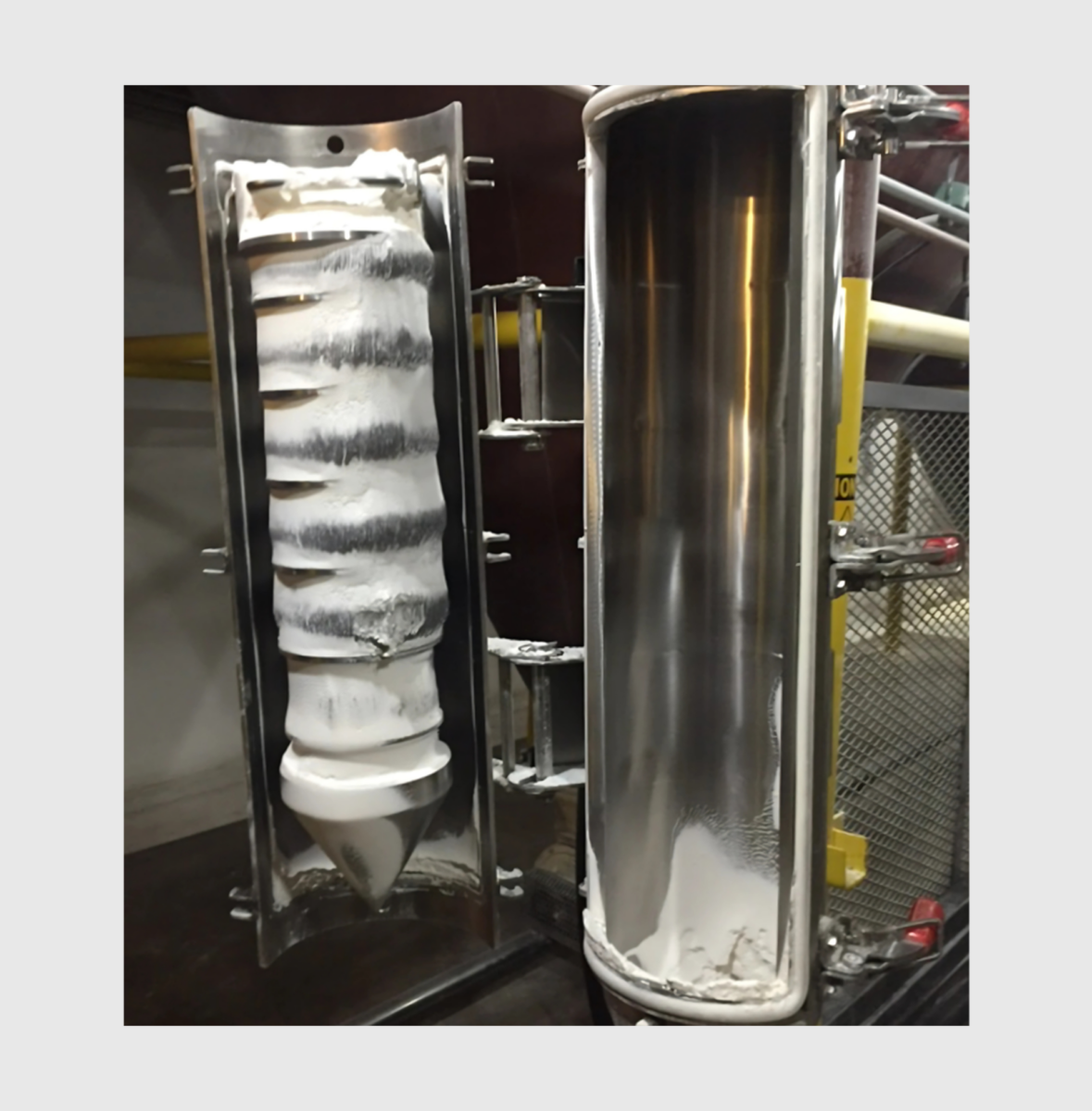

Pneumatic Line Magnet in Fine Powdered Starch Processing Application

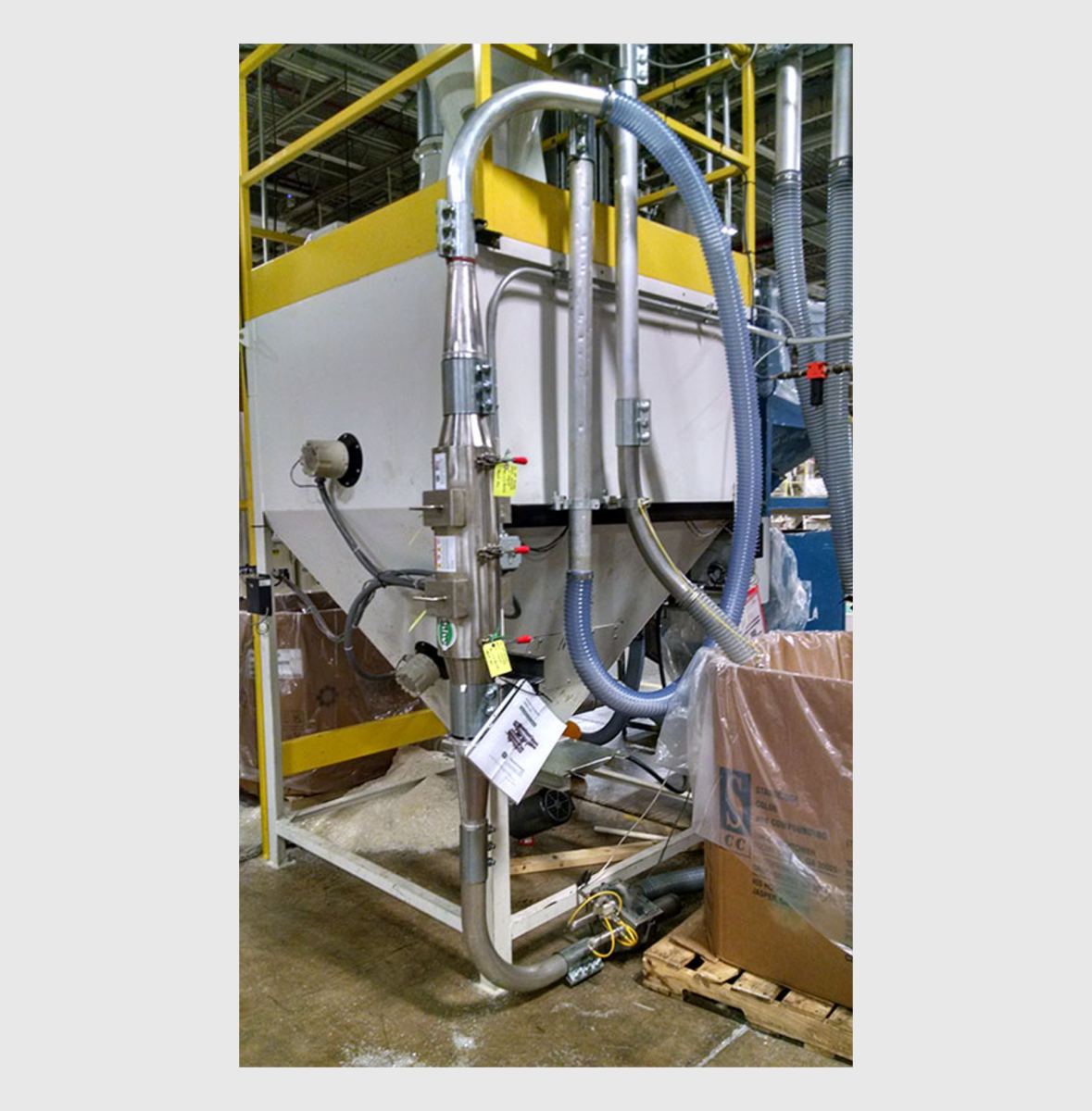

Pneumatic Line Magnet Installed in Pharmaceutical Processing Facility

Pneumatic Line Magnet Installed in High-Velocity Environment