Sensor enabled magnetic separators empower rice mill with magnet saturation data - allowing a reduction in cleaning shutdowns from once per day to once every three days. Reducing lost revenue by more than $1.5M in one year.

Drawing scrap from 13 presses at rates up to 15,000 lbs/hour, MPI installed more than 450 feet of underground scrap conveyance powers by an electric shaker. Drastically reducing downtime caused by scrap bottlenecks.

When a national mineral commodities supplier was facing facility-wide magnet strength loss, MPI auditors were hired to investigate. A complete review of the facility allowed the MPI team to solve the problem.

The largest beltless magnetic conveyor in company history responds to unique production challenges requiring rugged and virtually maintenance-free operation.

Manufacturer experiencing plugs from metal fines inside precision brake equipment installs Eco-Flow system from MPI for coolant cleaning. Sees significant reduction in downtime and tooling costs.

Unique production challenges required MPI to custom design and build a magnetic chute for this Co-Packing company. Installation increased yield, reduced employee hazards, and helped manage production dust.

Free Flow magnetic separator designed for tight spaces with automated self-cleaning replaces hard to reach plate magnets that require production downtime - resulting in significant increase in throughput.

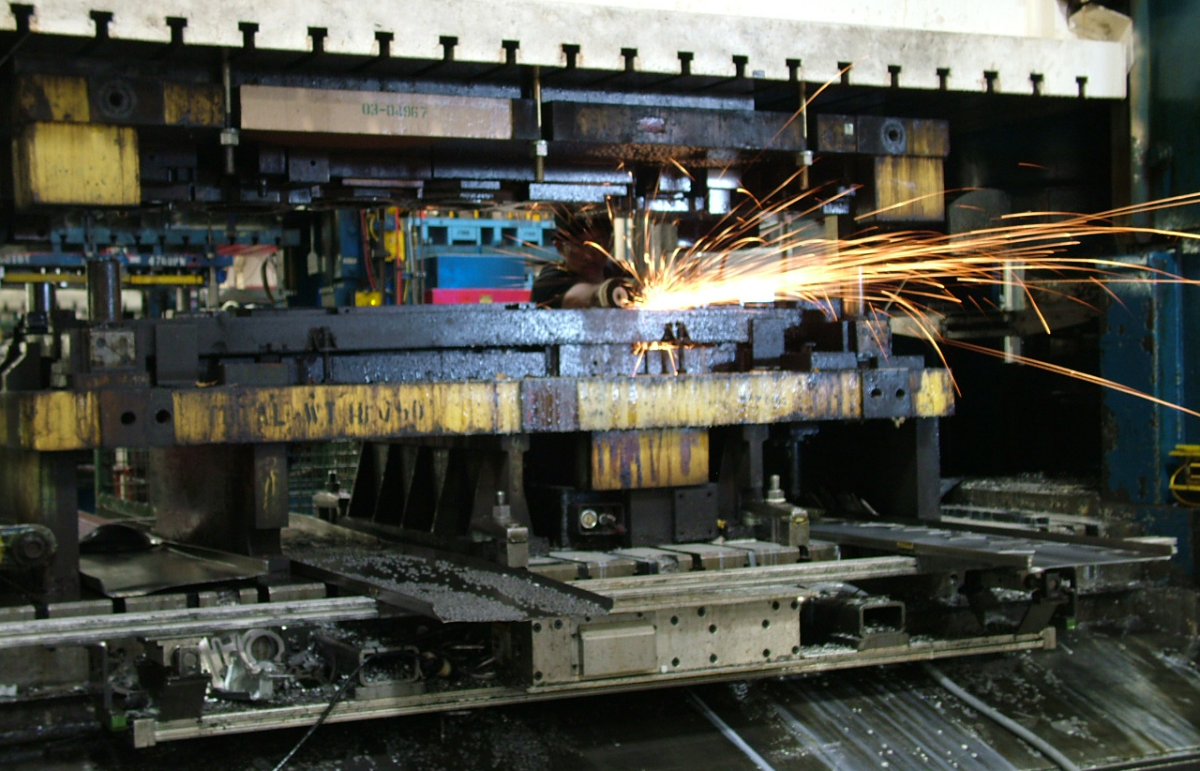

Virtually maintenance-free electric shakers reduce downtime in Radar Industries metal forming facility - offering a more reliable solution than pneumatic shakers - resulting in significant reduction in downtime.

Replacing air-powered shakers, the MPI M-50 electric shaker offered a low maintenance and economical solution for scrap management at Toledo Tool and Die. The M-50's reliability increased efficiency and reduced downtime.