Continuous, 24/7 Automatic Removal of Tramp Iron

MPI Magnetic Head Pulley Separation Roll maximizes product purity and protects your processing equipment with MPI’s Magnetic Head Pulley Separation Roll. Engineered for continuous, automatic separation of ferrous contaminants, this durable and efficient magnetic solution seamlessly integrates into belt conveyor systems. Ideal for bulk handling operations, MPI’s Separation Roll ensures 24/7 tramp iron removal—minimizing downtime, improving product quality, and preserving the integrity of downstream equipment.

Benefits of the Separation Rolls From Magnetic Products, Inc

-

Continuous 24/7 Separation

Automatically removes ferrous tramp iron from material flow without interrupting operations—ensuring constant protection and improved throughput.

-

Dual-Purpose Functionality

Serves as both a magnetic separator and head pulley, simplifying system design while maximizing conveyor efficiency.

-

Strong Magnetic Field

Utilizes high-intensity permanent magnets to capture both large and fine ferrous particles—even those embedded within product loads.

-

Maintenance-Free Operation

No external power supply or moving parts are required for magnetic operation, reducing maintenance costs and enhancing system reliability.

-

Rugged, Industrial-Grade Construction

Built to withstand demanding environments, the SR-series is constructed with durable materials to ensure long service life in heavy-duty applications.

-

Safe & Clean Product Flow

Effectively separates contaminants to maintain product purity and reduce risk of equipment wear, jams, or failure.

-

Custom Configurations Available

Available in a range of diameters and face widths to suit specific conveyor system requirements.

-

Eco-Friendly Performance

Operates without electricity for magnetic power, contributing to energy savings and sustainable facility design.

Separation Rolls Product Details

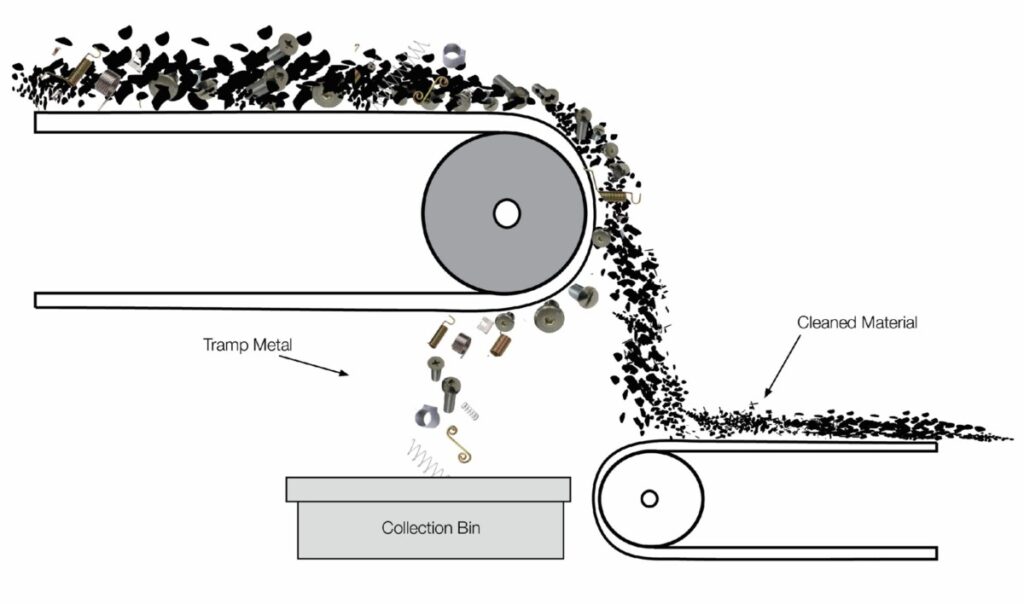

The MPI Separation Roll is strategically installed as the head pulley in a conveyor system. As material travels along the belt, it enters the magnetic field generated by the pulley. Ferrous tramp metals—such as nails, bolts, wire, and scrap—are immediately attracted and held tightly to the conveyor belt surface. While the clean, contaminant-free product is discharged from the top of the pulley at the end of the conveyor, the tramp iron remains attached to the belt as it wraps around the pulley. Upon reaching the underside of the roll, the tramp metal moves out of the magnetic field and falls freely into a designated chute or collection bin. This process runs continuously and automatically, with no need for operator intervention, ensuring a safer, cleaner material stream and reduced wear on equipment.

Separation Rolls Specifications

Magnet Circuits:

Axial (A)

This magnet circuit provides alternating north and south magnetic poles around the roll diameter, providing optimum magnetic field “reach-out” and a consistent magnetic pole across the roll width. This magnet design is ideal for capturing medium to larger types of tramp metal in moderate to deep product flows on the conveyer belt.

Salient (S)

This magnet circuit provides a large number of highly concentrated magnetic poles at intervals across the roll width and a consistent magnetic pole around the roll diameter. This magnet design is ideal for capturing small to fine types of tramp metal in shallow product flows on the conveyer belt.

Radial (R)

This magnet circuit provides a lower number of highly concentrated magnetic poles at intervals across the roll width as compared to a SALIENT design, improving magnetic field “reach-out” and a consistent magnetic pole around the roll diameter. This magnet design is ideal for capturing small to larger types of tramp metal in shallow to moderate flows on the conveyer belt.

Magnet Face Options:

Flat Stainless Steel (FS)

This is the most economical option offered and provides a durable non-magnetic stainless steel belt running surface.

Flat Stainless Steel with Centering Track Bar (FSTB)

This is an economical way to provide a degree of center belt tracking, without the expensive costs of crowning.

Crowned Stainless Steel (CS)

This is the most expensive option and offers a durable non-magnetic stainless steel-belt running surface with a belt centering crown.

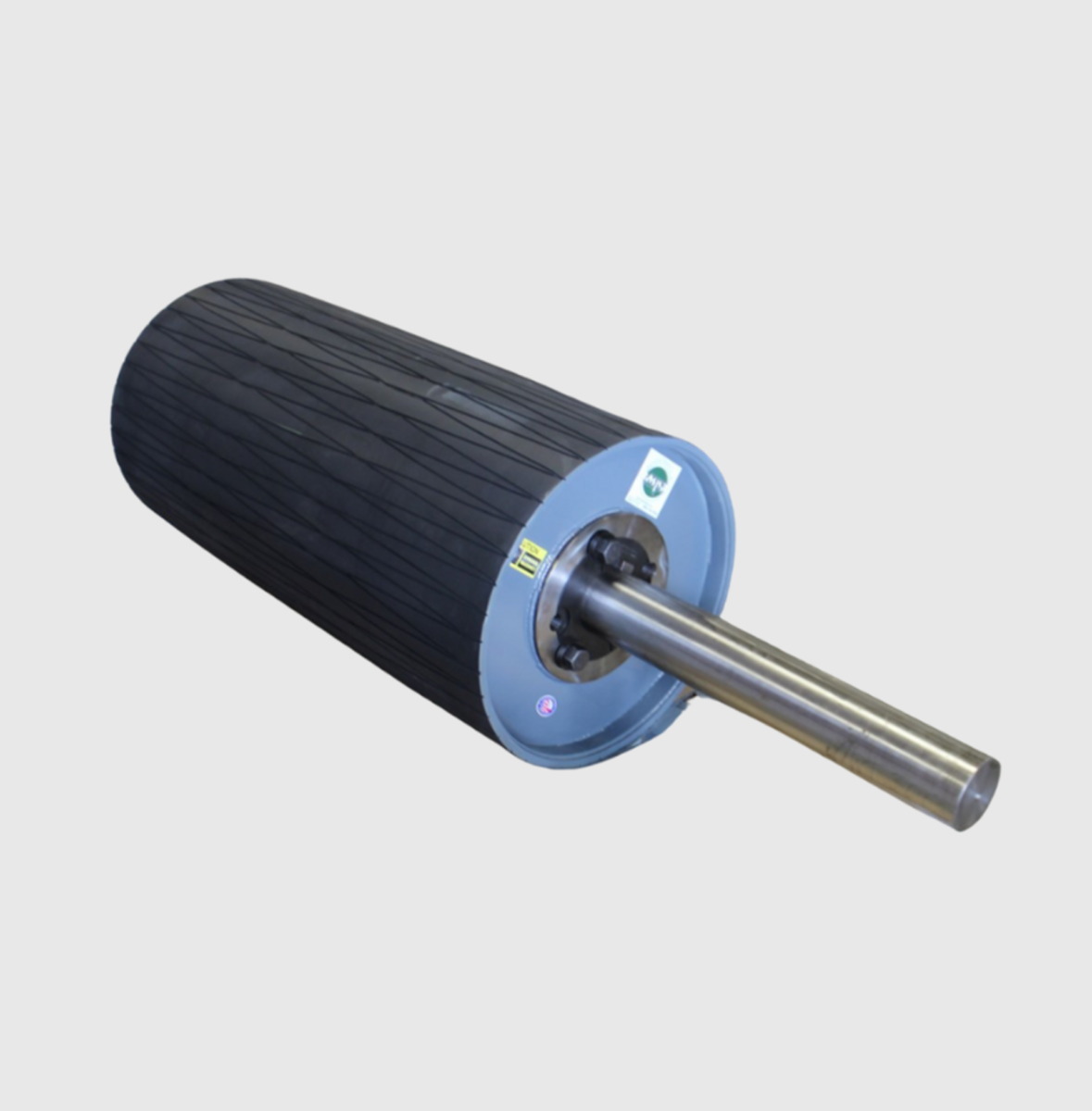

Crowned Vulcanized Rubber (CVR)

This option offers both an economical way to provide a belt-centering crown design and improved belt traction.

Crowned Vulcanized and Lagged Rubber (CVRL)

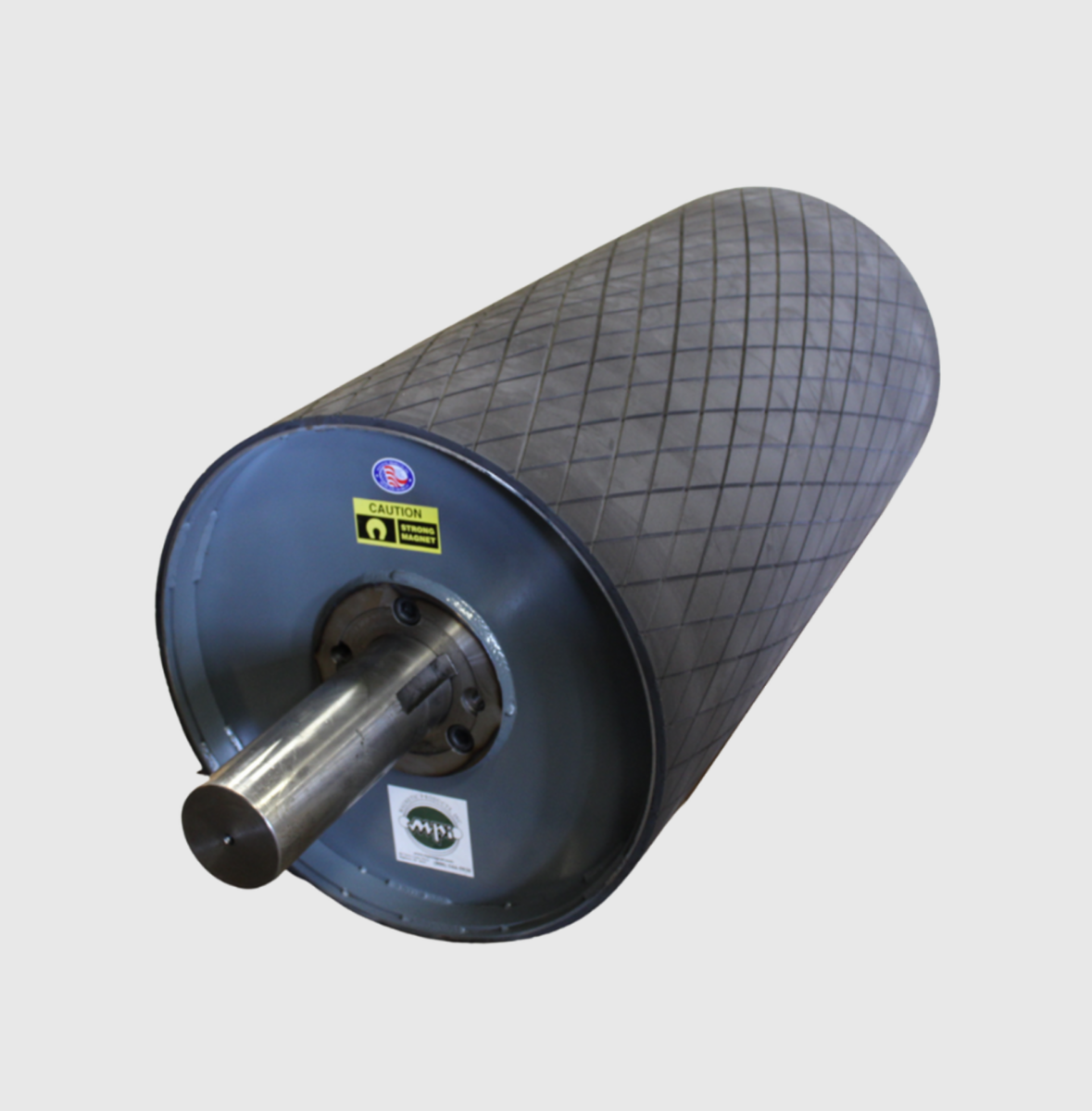

This option can be added to any vulcanized rubber roll where belt traction is critical. It is available in a variety of standard patterns, such as herringbone, diamond, etc.

Separation Rolls Installations & Variations

Optional Diamond Pattern Separation Roller for Large Belt Conveyor

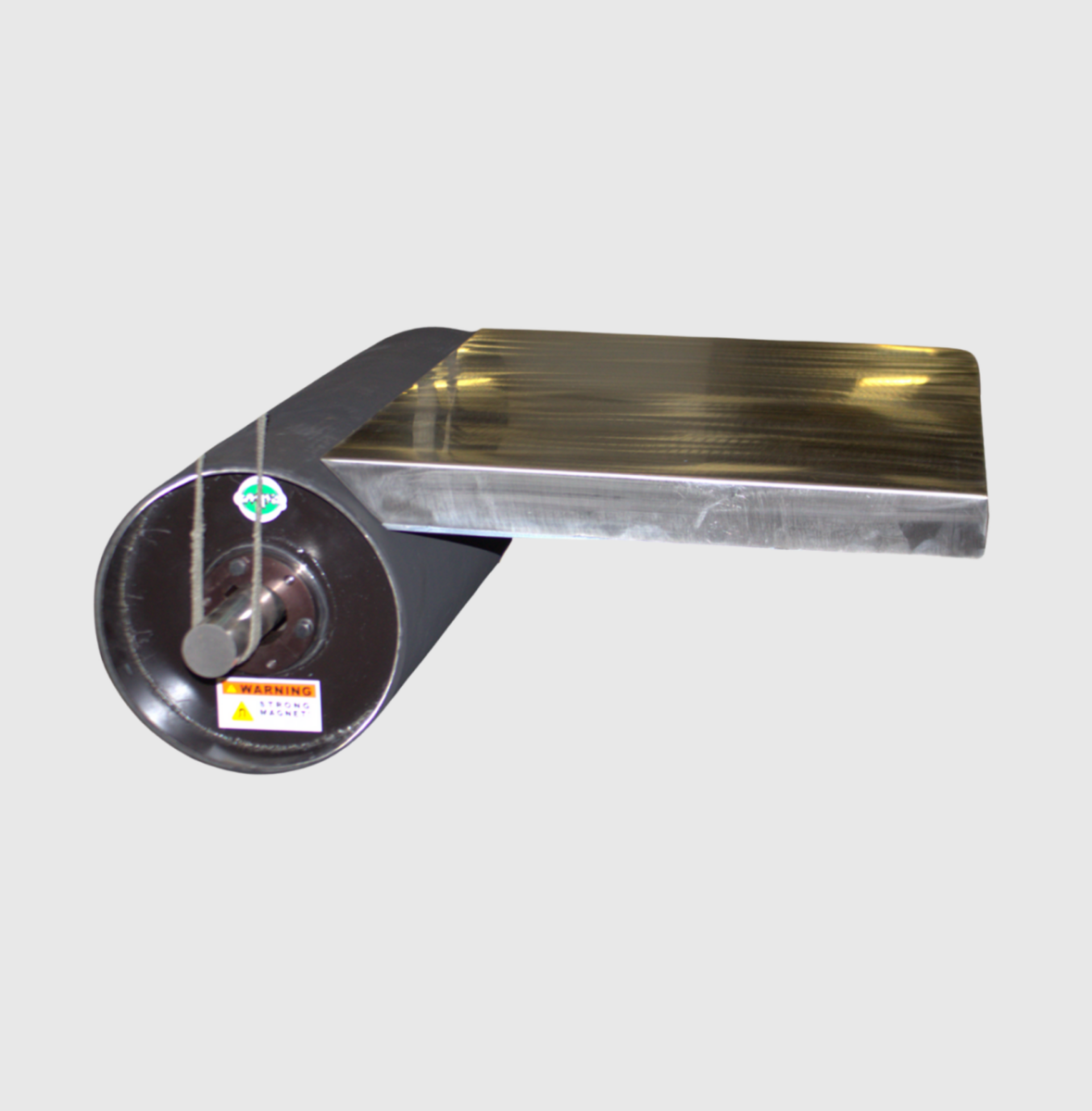

Suspended Magnetic Separation Roll with Custom Plate for Recycling Application

Optional Crowned Vulcanized Rubber Magnetic Separation Roll