Reliable Metal Detection Technology

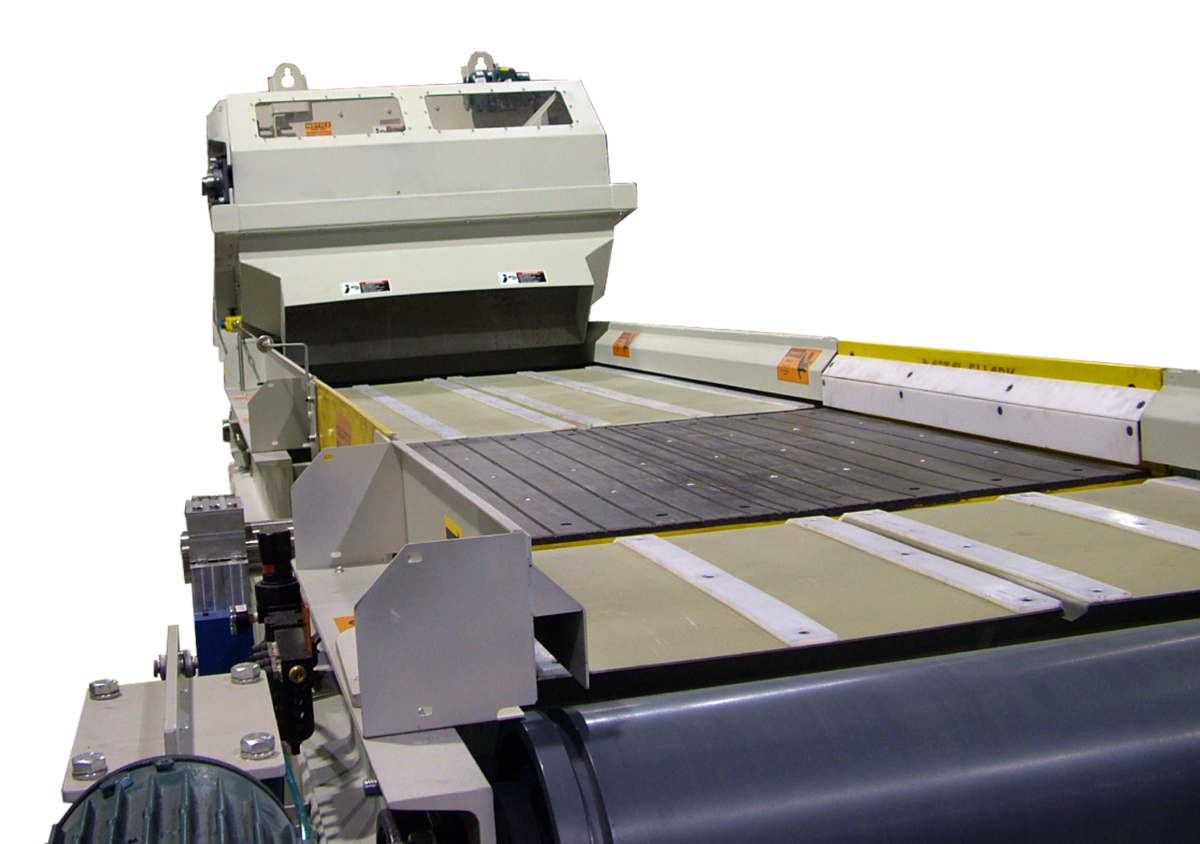

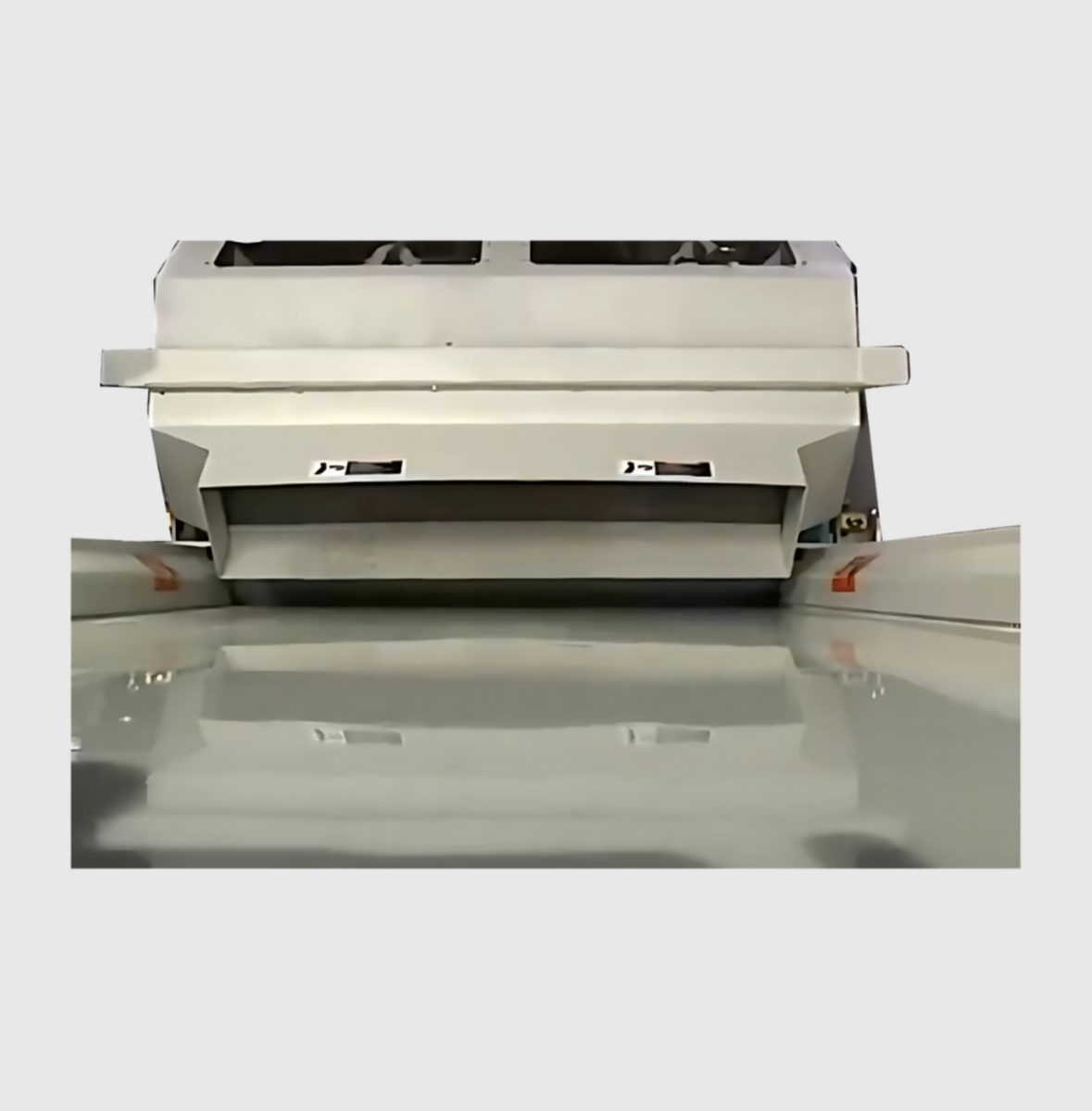

Detection sorting is a process that involves the separation of metals from a product stream by assessing their conductivity or ferrous permeability. The system employs dependable metal detection technology to oversee the product stream. When a conductive or ferrous metal is detected, the sensor triggers either a reject gate or an air blast downstream to facilitate the automatic removal of the metal. MPI’s Detection Sorter is a sophisticated system crafted to automatically recognize and isolate metallic contaminants from a product stream. Leveraging cutting-edge metal detection technology, this system guarantees the elimination of undesirable ferrous and non-ferrous metals, safeguarding processing equipment and maintaining product integrity across diverse industries.

Benefits of the Detection Sorting From Magnetic Products, Inc

-

Rugged Construction Paired with Highly Accurate Metal Detection

Built to withstand demanding industrial environments, ensuring long-lasting durability and performance. Advanced sensors ensure precise identification of even the smallest metal contaminants.

-

Fast and Automatic Metal Removal

Reduces manual labor and operational downtime by instantly removing detected metals. Minimized Product Loss with Smart Sorting technology ensures only contaminated materials are removed, preserving valuable product yield.

-

Customizable Sorting Mechanisms for Versatile Applications

Configurable with reject gates, pneumatic air jets, or conveyor diverters based on product flow requirements. Suitable for food processing, recycling, mining, pharmaceuticals, and bulk material handling.

-

Multi-Channel Technology & Configurations

Handles Up to 120 Product Configurations. Versatile programming capabilities allow quick adaptation to different products and production lines. Multi-Channel Technology allows for optimum recognition of metals, enhancing efficiency across various materials.

-

Maintenance-Free Operation & Auto Calibration

Frequent calibration eliminated thanks to digitalized circuitry, ensuring years of reliable performance with minimal upkeep. Provides fast and easy setup, automatically learning product characteristics to optimize detection without manual adjustments.

-

Advanced Digital Frequency, Filters & Phase Control

Eliminates drift after initial setup, removing the need for further electronic adjustments. Digital Noise Filters reduce interference from vibrations and shocks, preventing false positives and improving accuracy. The Digital Balance Control actively compensates for environmental factors such as temperature and humidity to maintain consistent accuracy.

-

User-Friendly Interface

Intuitive software with an on-board “teaching assistant” guides users through setup and operation. Streamlined Control Panel – Displays only the necessary information, making operation simple and reducing training time.

-

Seamless Integration

Designed to be easily integrated into existing production lines for enhanced quality control and equipment protection.

Detection Sorting Product Details

The Detection Sorter operates by continuously monitoring the product flow using high-sensitivity metal detection sensors. These sensors detect metallic contaminants based on two key properties:

- Conductivity Measurement – Identifies non-ferrous metals such as aluminum, copper, and stainless steel based on their electrical conductivity.

- Ferrous Permeability Detection – Recognizes ferrous metals like iron and steel based on their magnetic properties.

Once a metallic contaminant is detected, the system automatically activates a removal mechanism, which can be configured based on the application’s needs:

- Reject Gates – Mechanically diverts contaminated products from the product flow.

- Air Blast Systems – Uses a precisely timed burst of air to eject metal contaminants from the stream without disrupting operations.

Applications:

- Food Processing: Prevents metal contamination in packaged foods, grains, dairy, and baked goods.

- Recycling & Waste Management: Separates valuable metals from waste streams for efficient recycling.

- Pharmaceuticals: Ensures compliance with industry regulations by detecting metal contaminants in tablets and powders.

- Bulk Material Handling: Enhances sorting efficiency in industries such as mining, chemical processing, and plastics manufacturing.

Detection Sorting Specifications

Senses fine metal particles (FE 0.5 mm) over wide widths (3 ft. – 26.6 ft.) Detection of ferrous, non-ferrous and stainless steel metals down to 0.5mm Detection width ranging from 24” to 96” Segment sizes ranging from 4” (100mm) to 10” (250mm)

Compatibility Check - Detection Sorting Installations

Detection Sorting for Mixed E-Waste Material

Metal Detection Sorting from Coal Handling Before Combustion

Detection Sorting Ferrous Metal Removal from Rubber in Tire Recycling