Efficient and Affordable Way to Feed Material

MPI’s Vibratory Feeder Conveyors provide a highly efficient, low-maintenance solution for precisely moving, metering, or feeding bulk materials and parts in various industrial applications. Using controlled vibrations, these conveyors gently advance materials in a linear path without belts or moving mechanical components. Designed for reliability and flexibility, MPI vibratory conveyors are ideal for feeding shredders, sorters, and processing equipment, particularly where fragile parts, powders, or abrasives must be handled gently and cleanly. With customizable tray configurations, feed rates, and discharge options, these systems deliver smooth, continuous material flow with minimal wear and noise.

Benefits of the Vibratory Feeder Conveyor From Magnetic Products, Inc

-

Gentle, Non-Damaging Conveyance

Protects fragile or irregular materials like capsules, parts, or granules during transport.

-

Low Maintenance, No Belts or Chains

Minimal mechanical contact reduces wear and eliminates the need for lubrication.

-

Accurate, Controlled Feed Rates

Adjustable amplitude and frequency provide precision flow control for downstream equipment.

-

Hygienic and Easy to Clean Designs

Available in stainless steel with smooth surfaces for food, pharma, and sanitary applications.

-

Highly Customizable Tray Designs

Troughs can include screens, covers, diverters, or discharge chutes tailored to process needs.

-

Quiet and Energy-Efficient Operation

Reduced noise and power consumption compared to motorized belts or pneumatic conveyors.

-

Integrated Controls for Automation

VFDs and control panels allow synchronized operation with sorting, weighing, or processing systems.

-

Adaptable for Harsh or Dusty Environments

Sealed or covered designs are available for dusty, abrasive, or hazardous environments.

Vibratory Feeder Conveyor Product Details

-

Material Loading

Bulk material or parts are fed into the tray from hoppers, bins, or upstream equipment.

-

Vibratory Motion Activated

The conveyor’s drive system (electromagnetic or motor-driven) generates precise oscillating motion.

-

Transfer of Energy

The tray vibrates forward, linearly, transferring that movement to the product.

-

Controlled Flow Movement

Material advances smoothly down the tray at a rate determined by frequency, amplitude, and tray angle.

-

Discharge or Metering

At the end of the tray, material exits into the next stage (screeners, sorters, shredders, etc.) or accumulates for batching.

-

Ongoing Operation

The system runs continuously or on demand, with minimal operator input or need for maintenance.

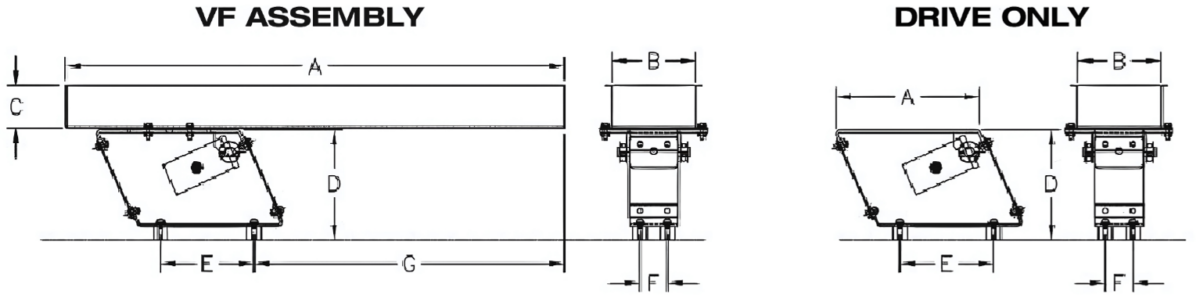

Vibratory Feeder Conveyor Specification Table

US Customary Units

| VIBRATORY FEEDER MODEL # | STANDARD DIMENSIONS | (A) OVERALL LENGTH (IN.) | (B) DRIVE OPENING (IN.) |

|---|---|---|---|

| VF-2-318 | (0.81 CUBIC FT. PER MIN. / 2-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 2 IN. BASE | 18 | 3 |

| VF-2-424 | (0.81 CUBIC FT. PER MIN. / 2-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 2 IN. BASE | 24 | 4 |

| VF-2-620 | (0.81 CUBIC FT. PER MIN. / 2-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 2 IN. BASE | 20 | 6 |

| VF-4-524 | (1.76 CUBIC FT. PER MIN. / 2-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 3 IN. BASE | 24 | 5 |

| VF-4-618 | (1.76 CUBIC FT. PER MIN. / 2-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 3 IN. BASE | 18 | 6 |

| VF-4-720 | (1.76 CUBIC FT. PER MIN. / 2-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 3 IN. BASE | 20 | 7 |

| VF-8-636 | (3.14 CUBIC FT. PER MIN. / 3-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 5 IN. BASE | 36 | 6 |

| VF-8-830 | (3.14 CUBIC FT. PER MIN. / 3-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 5 IN. BASE | 30 | 8 |

| VF-8-1224 | (3.14 CUBIC FT. PER MIN. / 3-IN. PAN DEPTH / 7.75 IN. DRIVE HEIGHT / 6.75 IN. DRIVE WIDTH / 5 IN. BASE | 24 | 12 |

Vibratory Feeder Conveyor Installations & Variations

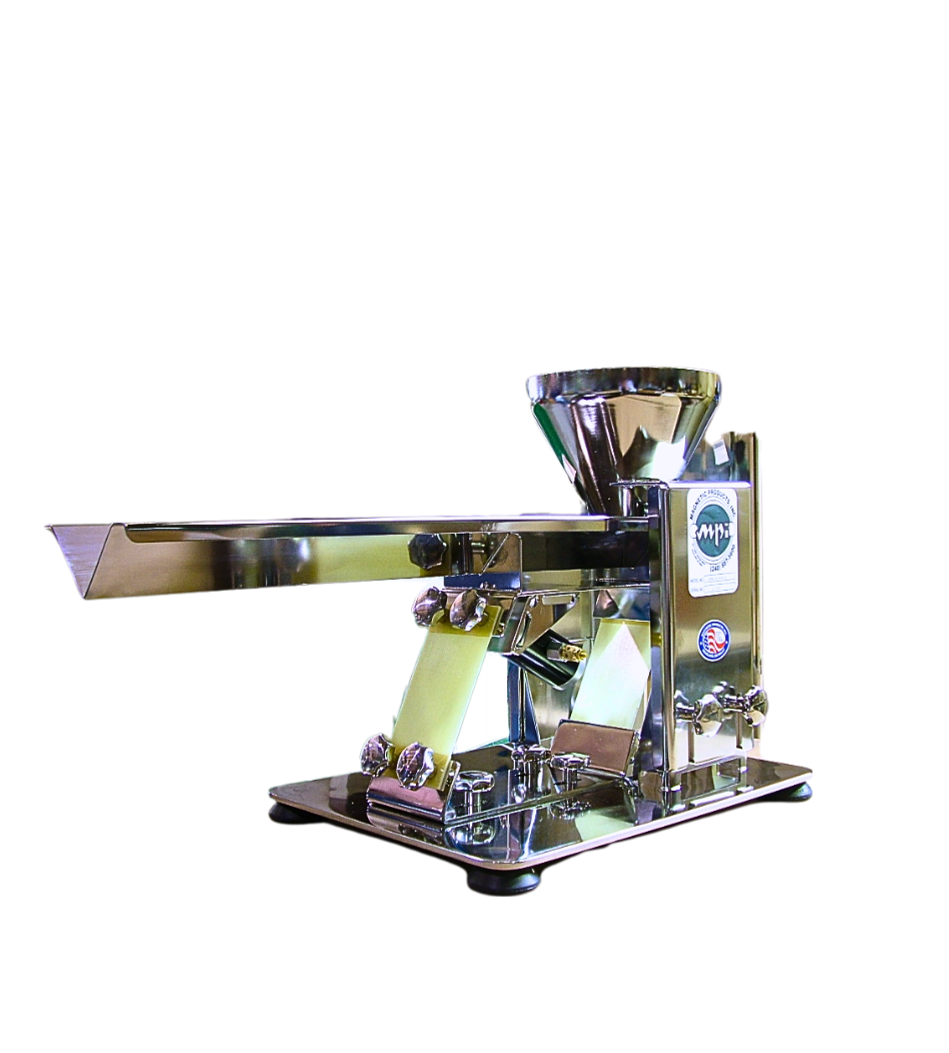

Small Vibratory Feeder for Processing Powder and Granulats Up To 2 Tons/Hour

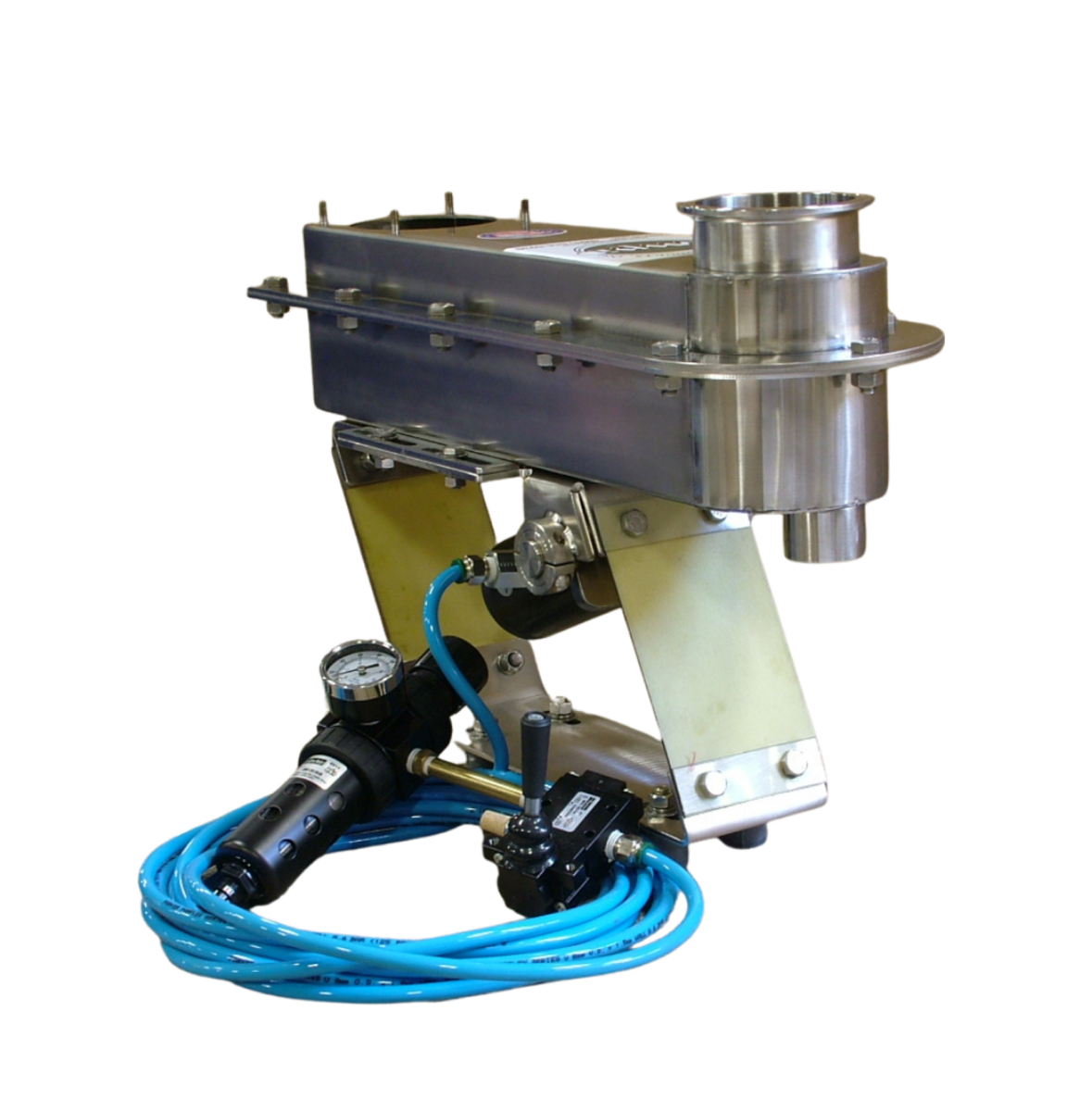

Mid-Sized Vibratory Feeder Used in Manufacturing Up To 4 Tons/Hour

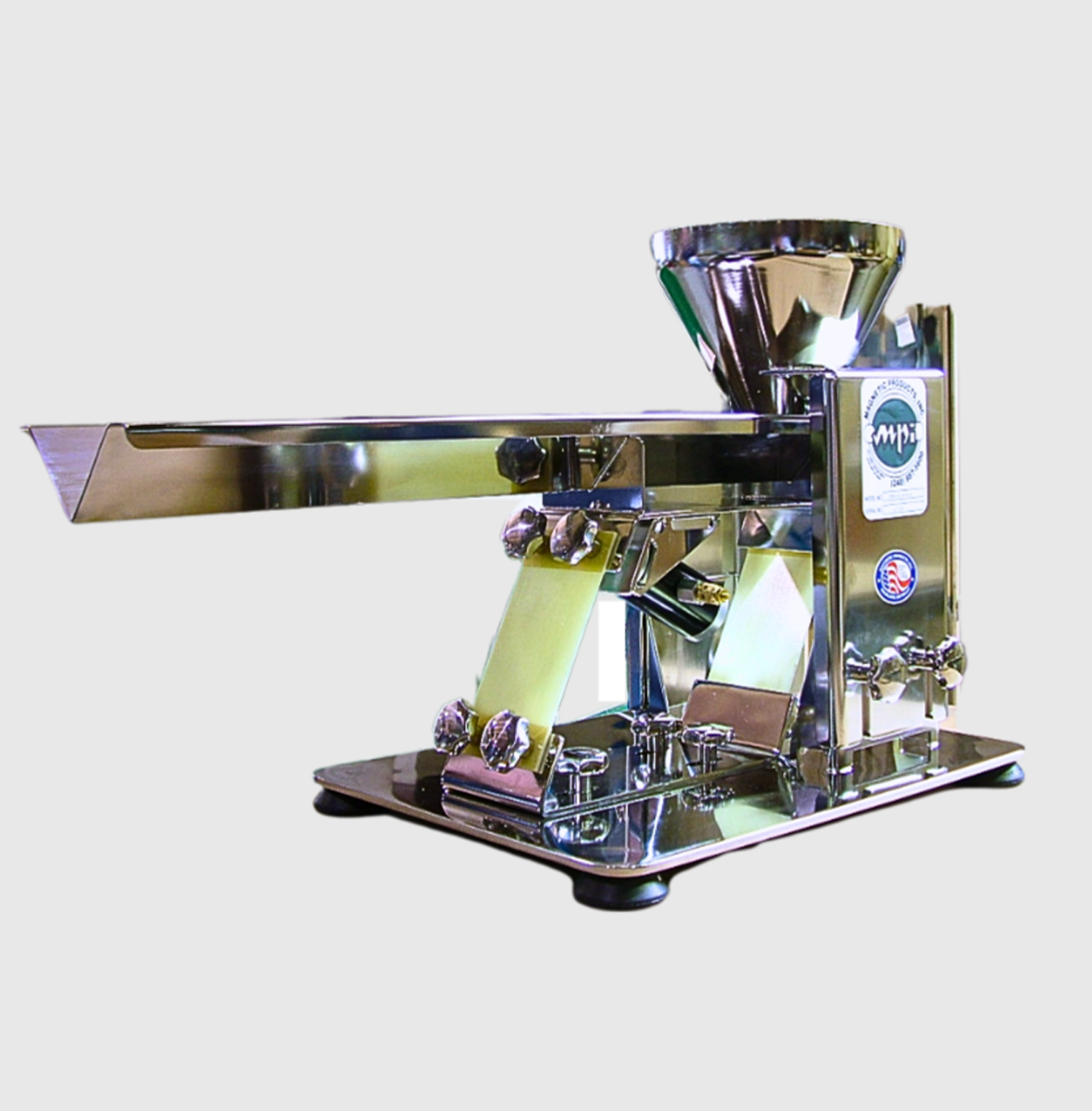

Large Vibratory Feeder Used in Food Processing Up To 8 Tons/Hour