Magnetic Separation can be done in processes that convey materials by gravity-free flow, pneumatically, and as liquids and magnetic filtration.

Magnetic separation is a process whereby magnetically susceptible material is extracted from a mixture. Magnetic separators are useful in high volume process flows. They are placed inline so as not to introduce any foreign contaminants from external sources into your production facility.

Magnetic Separation can be done in processes that convey materials by gravity-free flow, pneumatically, and as liquids and magnetic filtration.

- Gravity-Free Flow separators remove ferrous tramp metal from gravity, free-falling conveying systems

- Pneumatic magnetic separators remove ferrous tramp metal from pneumatic conveying applications

- Liquid magnetic separators remove ferrous tramp metal from liquids in sanitary applications

Magnetic Separator Options from Magnetic Products, Inc

Bulk Gravity Magnetic Separators

- Tube Magnets: Most economical way to capture fine ferrous tramp metal in medium flows.

- Grate Magnets: Remove medium and small-size ferrous tramp metal in gravity-fed vertical chutes, hoppers, housings, surge or catch bins.

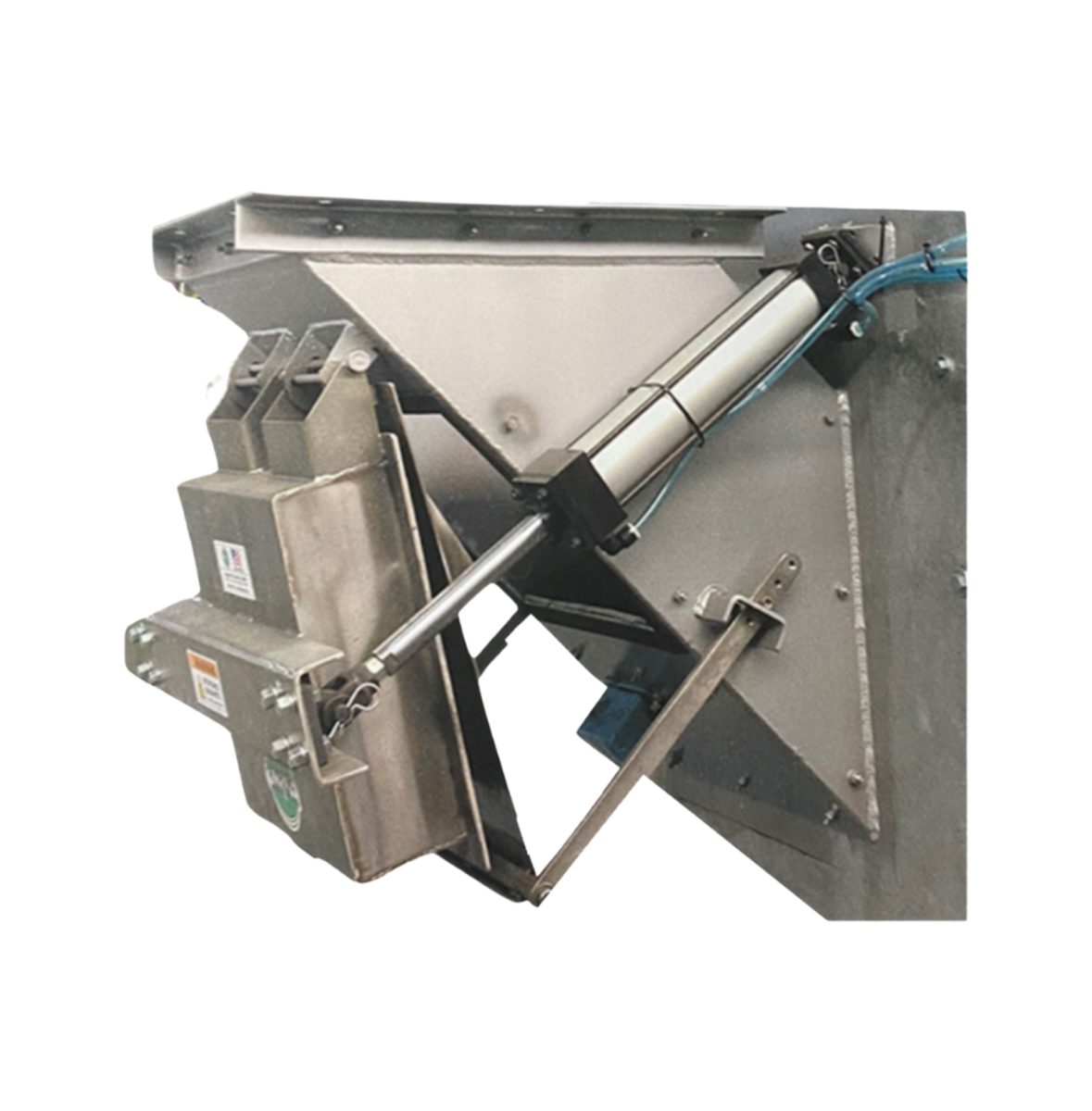

- Plate Magnets: Capture fine-to-medium ferrous tramp metal in chute applications.

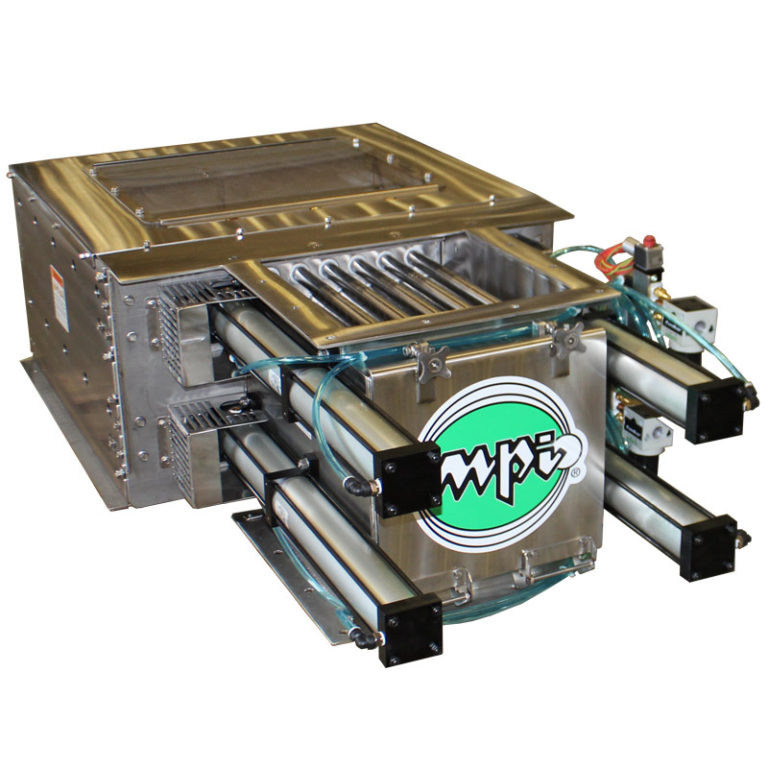

- Drawer Magnets: Most common method to capture fine ferrous tramp metal in medium flows.

- Chute Magnets: Magnet element is installed around the product flow, eliminating potential wear from highly abrasive products.

- Free-Flow Magnets: Designed for abrasive products such as those in grain or mining applications.

- Magnetic Rotary Feeder: Designed to protect and control feeding characteristics of free-flowing materials above hammer mills.

Pneumatic Magnetic Separators

- Pneumatic Line Magnet: Raised poles with a dust-tight, sanitary seam-welded construction.

- Inline Pneumatic Drawer Magnet: Ideally suited to capture small contaminants in pneumatically conveyed applications.

- Inline Pneumatic Plate Magnet: Optimal removal of ferrous tramp metal for gravity chute applications.

- Pneumatic Tube Magnet: Easily installed into existing product conveying lines.

Liquid Processing Magnetic Separators

- Liquid Plate Trap: For applications with viscous product or products that do not flow easily.

- Liquid Finger Trap: For maximum ferrous removal in liquid lines; sanitary construction for food processing.