Essential Workshop Tool

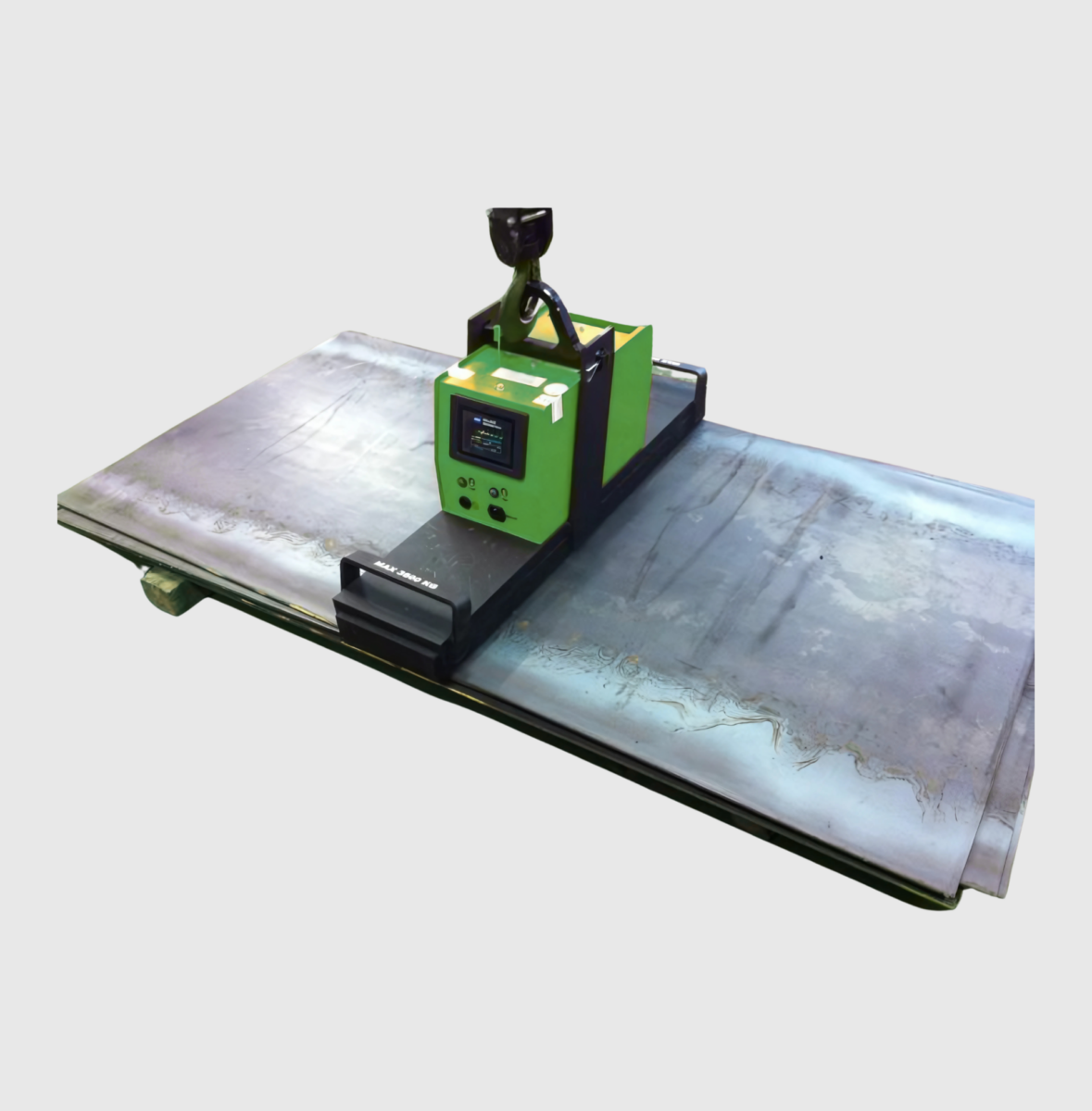

The MPI Battery Lifting Magnet (BM) is a remote-controlled, battery-powered solution designed for efficient and safe lifting of heavy ferrous materials in workshops and industrial settings. With a lifting capacity ranging from 2,976 lbs. to 11,023 lbs., it is ideal for handling steel sheets, blocks, and machine parts. Equipped with a synoptic display and safety features like low battery alerts and shutdown blocking during lifting, it prioritizes user safety. The magnet operates for a minimum of eight hours on a single charge and offers Variable Force and Tip-Off functions, allowing versatile use for different material thicknesses. Its ergonomic, self-contained design eliminates the need for slings or chains, enhancing productivity and reducing manual strain in environments such as steel service centers, warehouses, and fabrication shops.

Benefits of the Battery Lifting Magnet From Magnetic Products, Inc

-

Cordless Power

Fully battery-powered—no external power source or cables required during lifting.

-

Remote or Button-Controlled Activation

Simple push-button operation for safe, fast magnet engagement and release.

-

Zero Residual Magnetism

Clean load release prevents sticking and damage to delicate surfaces.

-

Handles Flat and Round Materials

Versatile lifting for sheets, plates, beams, pipes, or round bar stock.

-

Fail-Safe Holding Force

Holds securely during operation—even if battery power depletes.

-

Rechargeable Battery Pack

Long-lasting operation per charge with quick, convenient recharging.

-

Ergonomic and Portable

Compact, lightweight design makes lifting and positioning easier in tight spaces.

-

Improves Operator Safety

Reduces the need for manual rigging, chains, and hooks—minimizes lifting-related injuries.

Battery Lifting Magnet Product Details

The Battery Lifting Magnet houses an internal permanent magnet system controlled by an electric actuator powered by a rechargeable battery. When the operator presses the engage button (on the magnet or optional remote), the actuator shifts the magnetic core to activate its magnetic field outward, clamping securely onto the ferrous load. Once attached, the magnet holds the material with no additional battery drain. To release the load, the operator presses the disengage button, which shifts the core back, collapsing the magnetic field and dropping the part with zero residual hold.

The MPI Battery Lifting Magnet (BM), equipped with a remote control, is the perfect solution for situations where manual lifting is impractical. The remote allows for operation from up to 33 feet away.

This battery-powered lifting magnet is a must-have tool for workshops, particularly in receiving and shipping areas dealing with steel stock. It's also ideal for use with transportation crane accessories, burning tables, machine tools, and sawing applications.

The BM series is capable of managing loads ranging from 2,976 lbs. to 11,023 lbs., making it suitable for handling large steel sheets, heavy blocks, various flame-cut materials, machine parts, and smooth castings or forgings.

All BM battery-operated lifting magnets prioritize safety. They feature a synoptic display with a battery level LED indicator, shutdown blocking during the lifting process (thanks to the lifting eye sensor), and both audible and visual alerts for low battery levels. Users can engage the lifter using the controls on the magnet body or via the IR remote control from distances of up to 33 feet.

These battery-powered magnetic lifters are fully self-contained, offering a minimum of eight hours of operation with a 50% duty cycle. MPI’s BM series also come with Variable Force and Tip-Off functions, making it a versatile tool for lifting various steel plates—whether they are thin or thick and whether lifting several at once or just one for a controlled drop. This adjustable force makes it easy to pick up thin metal sheets from surfaces like machine tables, pallets, and benches.

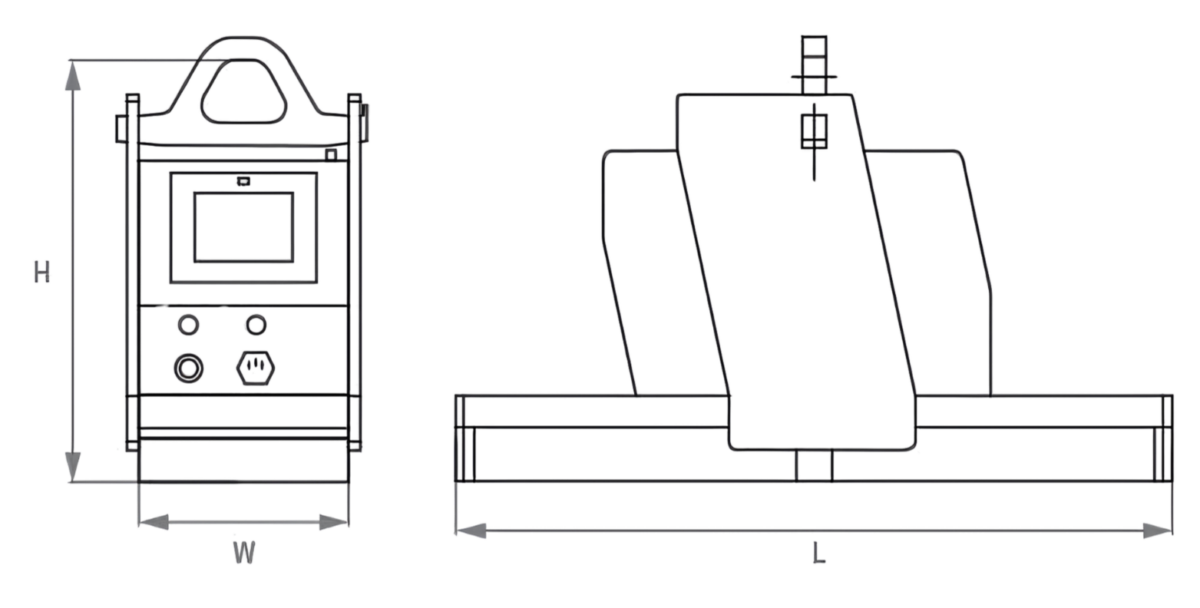

Battery Lifting Magnet Specification Table

US Customary Units

| MODEL # | LIFTING CAPACITY FOR FLAT MATERIALS (LBS.) | TESTING LIFTING CAPACITY (LBS.) | WIDTH x LENGTH BASE (IN.) | HEIGHT UP TO CRANE HOOK (IN.) | WEIGHT (LBS.) | BUILT IN BATTERY | TYPE OF BATTERY |

|---|---|---|---|---|---|---|---|

| BM2976 | 2,976 | 5,952 | 9.5 x 10.7 | 18.1 | 132 | 12V/35Ah | FG12-35D |

| BM5511 | 5,511 | 11,022 | 9.5 x 15.7 | 18.1 | 159 | 12V/75Ah | FG12-75D |

| BM7936 | 7,936 | 15,872 | 9.4 x 41.3 | 18.1 | 397 | 12V/75Ah | FG12-75D |

| BM11023 | 11,023 | 22,046 | 10.3 x 47.2 | 18.1 | 448 | 12V/75Ah | FG12-75D |

Compatibility Check - Battery Lifting Magnet Installations

Battery Lifting Magnet Used for Moving Large, Thin Sheets Without Damage

Battery Lifting Magnet Used to Prevent Sticking and Surface Damage

BLM Chosen for It's Safety and Versatility in Lifting Sheets, Plates, Beams, Pipes and Bars