Achieve More Efficient Machining

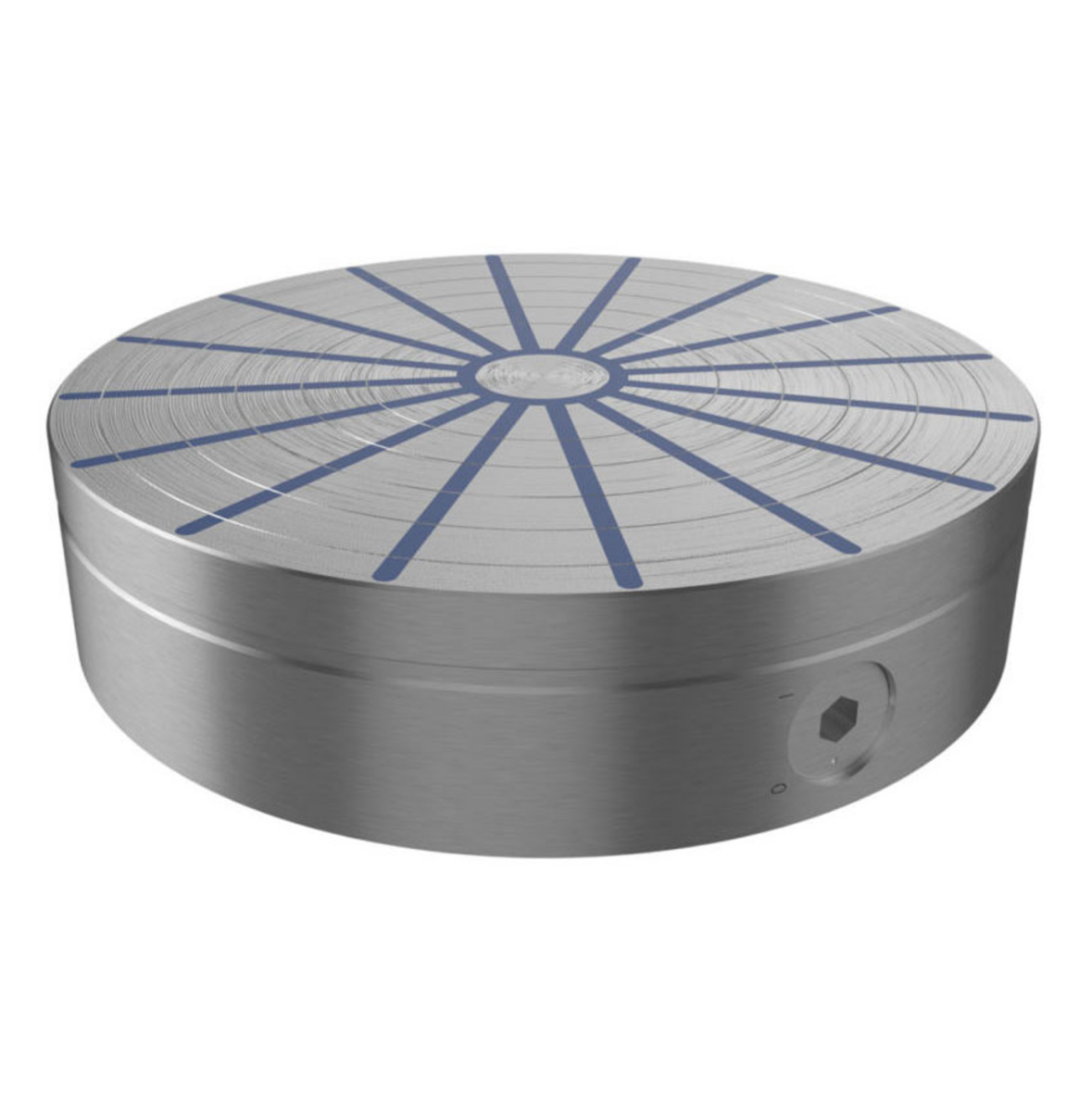

MPI’s Double Rare Earth Round Chuck is a high-performance, power-free workholding solution designed to deliver exceptional magnetic clamping force and deeper flux penetration for demanding grinding and turning of large or thick round ferrous workpieces. Utilizing two stacked circuits of high-energy rare earth magnets, this advanced chuck provides greater holding strength and uniform clamping across the entire face, minimizing part vibration and movement even under aggressive cuts. Its robust, sealed construction resists coolant and swarf intrusion, ensuring reliability in toolrooms and high-production machining environments where precision, repeatability, and safety are paramount.

Benefits of the Double Rare Earth Round Chuck From Magnetic Products, Inc

-

Double Rare Earth Magnet Circuits

Twice the magnetic power and deeper field reach compared to standard single-circuit chucks.

-

Exceptional Clamping Force

Ideal for large-diameter, thick, or heavy round parts requiring high holding torque.

-

Uniform Pole Configuration

Consistent magnetic flux ensures minimal part deflection and excellent surface finish.

-

Power-Free Operation

The permanent magnet design needs no electricity and has fail-safe holding even in power loss.

-

Manual On/Off Switching

Simple lever or wrench-controlled switching for quick engagement and clean part release.

-

Sealed Heavy-Duty Build

Withstands harsh grinding fluids, chips, and abrasive swarf.

-

Supports Heavy-Duty Grinding & Turning

Designed for deep cuts, roughing passes, and precision finishing alike.

-

Reduces Fixture Complexity

Replaces multiple mechanical clamps, improving setup time and operator safety.

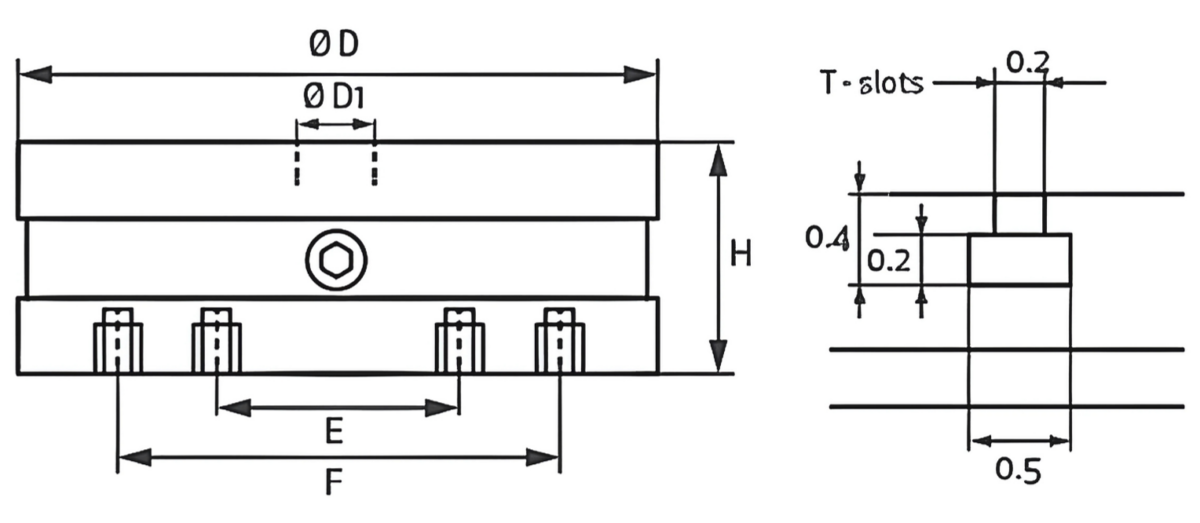

Double Rare Earth Round Chuck Product Details

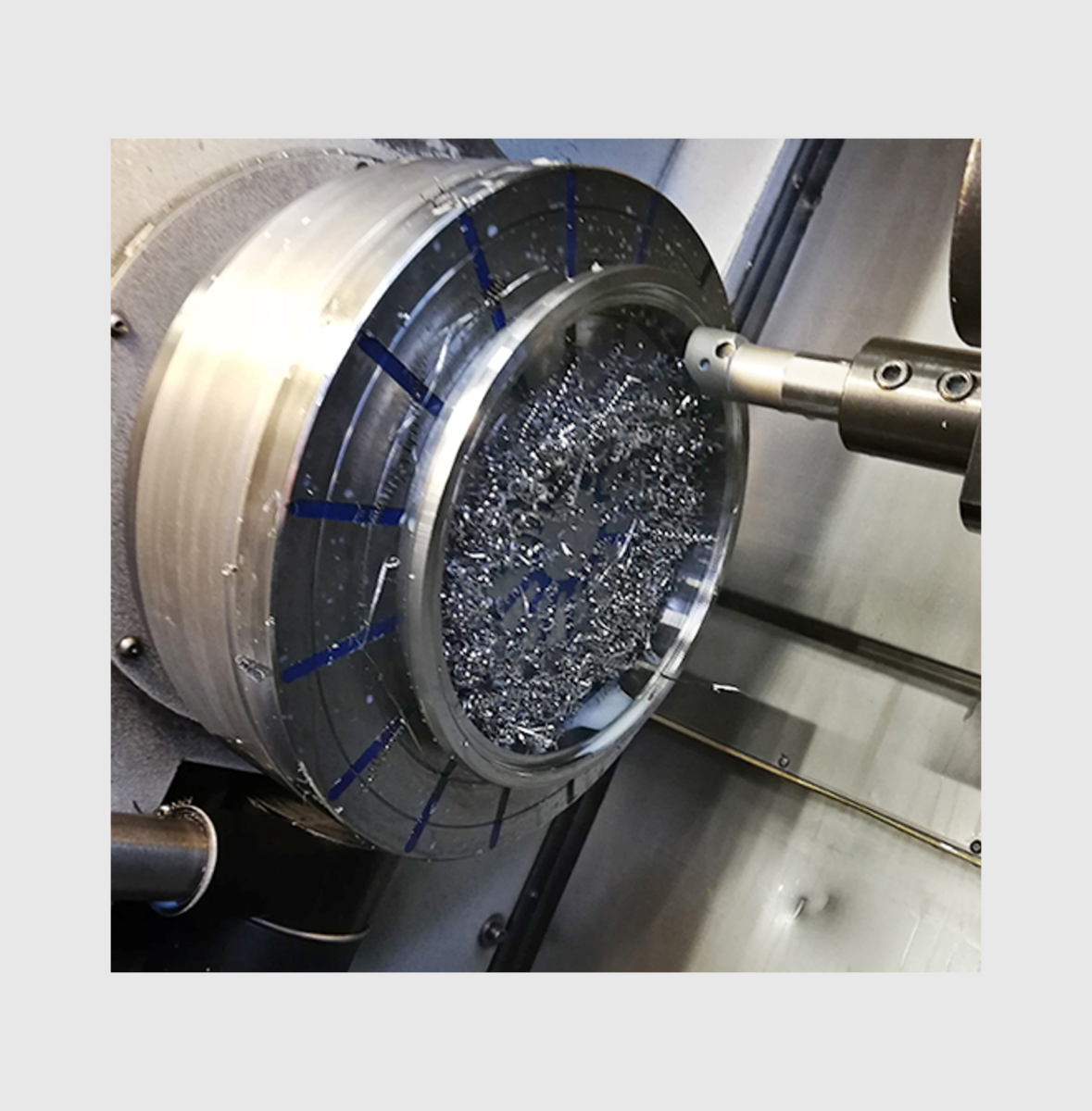

Due to the top plate with radial poles, the MPI Double Rare Earth permanent chuck is primarily designed for turning and grinding round and ring-shaped workpieces. The advantage is the possibility to machine the front, inner, and outer diameter of the workpiece in one operation.

Install

Secure the Double Rare Earth Round Chuck to your rotary table, surface grinder, or vertical turning lathe.

Place Workpiece

Center the large, round or ring-shaped ferrous part directly on the chuck face.

Engage Magnetic Hold

Use the switch lever or hex key to rotate the internal mechanism, aligning both rare earth magnet circuits. This activates a deep, strong magnetic field.

Clamp

The magnetic force penetrates deep into thick parts, locking them firmly against the chuck with uniform pressure across the face.

Machine

Carry out heavy grinding or turning operations with reduced part shifting, vibration, or chatter risk.

Release

When finished, rotate the switch back to OFF to collapse the magnetic field.

Unload

Remove the workpiece easily — no residual magnetism remains.

Double Rare Earth Round Chuck Specification Table

US Customary Units

| MODEL # | DIAMETER (IN.) | HEIGHT (IN.) | CENTER T-SLOT DIAMETER (IN.) | INNER LOCK DIAMETER (IN.) | OUTER LOCK DIAMETER (IN.) | WEIGHT (LBS.) |

|---|---|---|---|---|---|---|

| RC-130-REN | 5 | 2.2 | 0.59 | - | 3.9 | 11 |

| RC-150-REN | 6 | 2.2 | 0.59 | 3.15 | 4.7 | 16 |

| RC-200-REN | 8 | 2.2 | 0.59 | 3.15 | 4.7 | 16 |

Compatibility Check - Double Rare Earth Round Chuck Installations

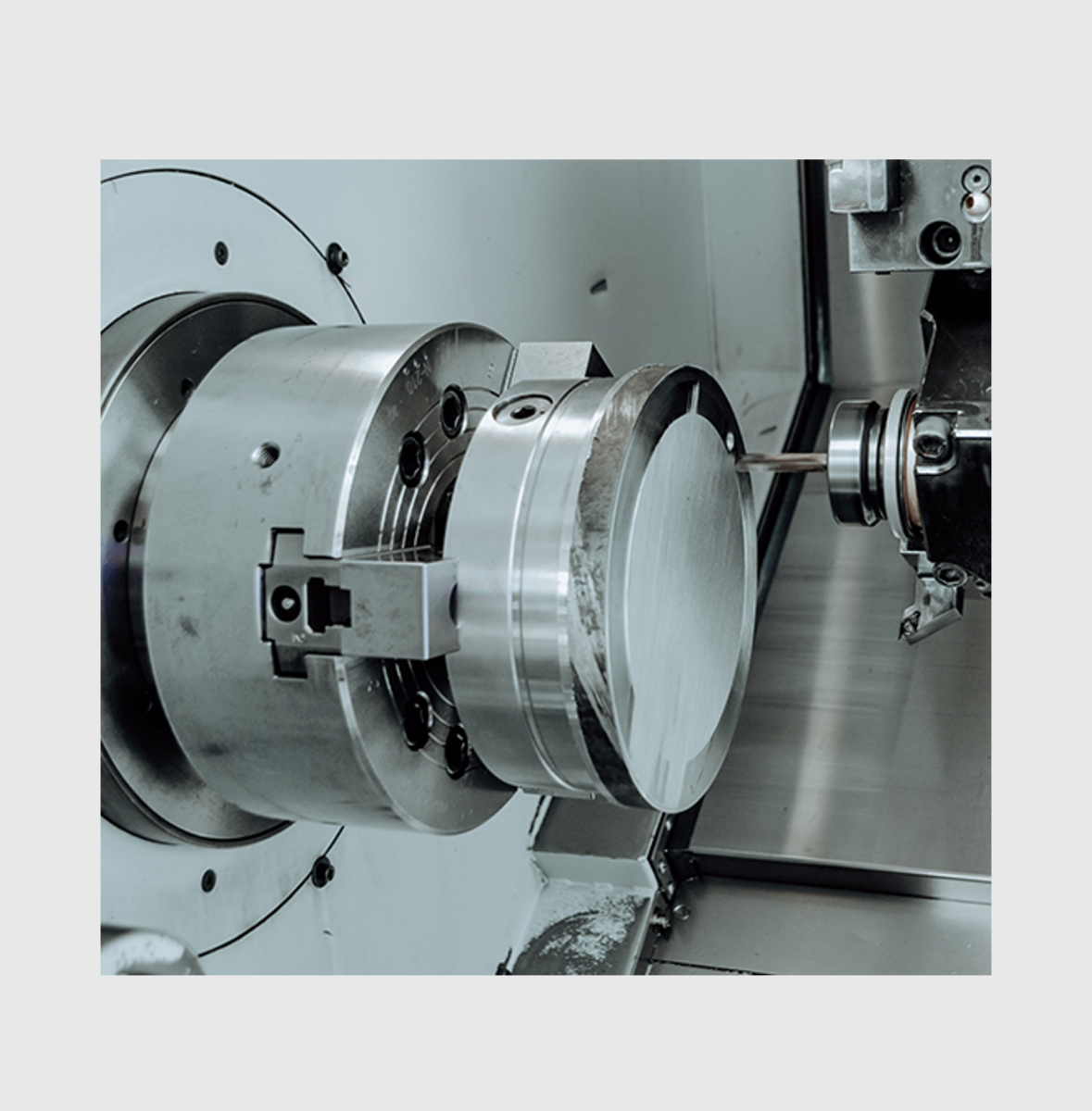

MPI Double Rare Earth Round Chuck Ideal for Heavy Rotary Surface Grinding

MPI Double Rare Earth Round Chuck for Turning or Facing Large Round Parts on Vertical Lathes or Rotary Tables

MPI Double Rare Earth Round Chuck for High-Accuracy Production Grinding Where Secure Clamping is Critical