Simplified Scrap Management

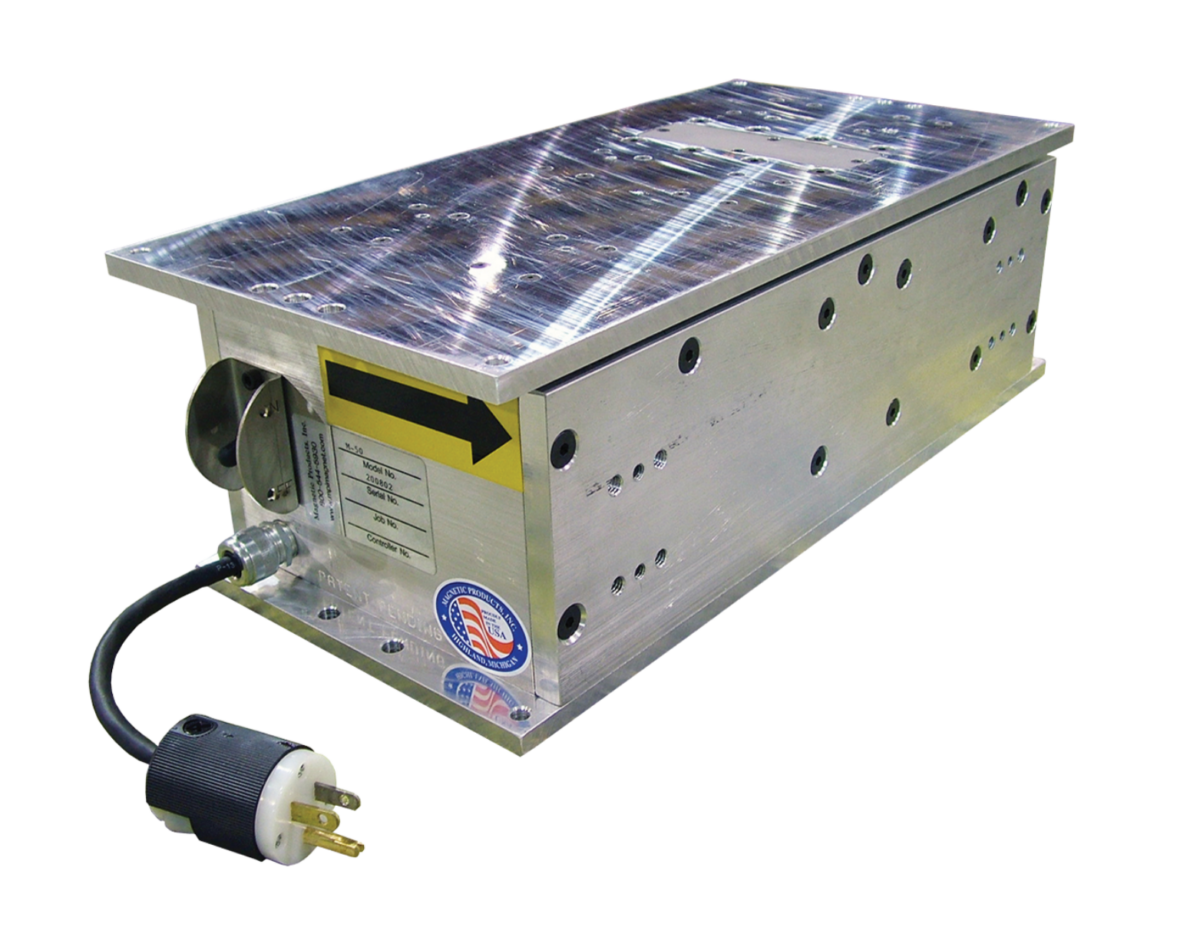

The M-50 Electric Shaker Conveyor, patented under #US-008,752,695-B2, is designed to efficiently eliminate scrap metal from medium-sized stamping presses with a crossbar of up to 36 inches. This turnkey system offers ease of use, requiring simple assembly, mounting, connection to a 110v power source, and attachment of pans, enabling immediate operation. It operates without maintenance, air, or lubrication, and features a factory preset speed to ensure optimal performance, minimizing any potential production slowdowns by removing adjustable components. The M-50 is built for heavy-duty applications in multi-press environments, using a robust electric linear drive for consistent vibratory motion and accommodating multiple pans for centralized scrap collection. Its durable construction, silent operation, and low maintenance make it an ideal solution for industrial scrap management, enhancing efficiency and workplace safety.

Benefits of the M-50 Electric Scrap Shaker From Magnetic Products, Inc

-

High-Load, Heavy-Duty Design

Built to move larger, heavier scrap volumes generated by high-tonnage presses and extended lines.

-

Powerful Electric Operation

Eliminates the need for compressed air — lowering energy usage and simplifying installation.

-

Supports Multi-Tray Configurations

Can drive multiple pans or scrap tray segments from a single drive unit.

-

Continuous, Reliable Scrap Flow

Reduces downtime and labor by automatically clearing scrap from press pits and floor areas.

-

Low Maintenance

Few wear parts, sealed bearings, and rugged construction minimize service needs.

-

Quiet and Clean Operation

Smooth electric drive generates less noise than pneumatic shakers and improves workplace conditions.

-

Flexible Integration

Compatible with various presses, lines, and conveyor discharge setups.

-

Safety-Enhancing Workflow

Automates scrap handling to eliminate manual shovel-outs and reduce trip hazards.

M-50 Electric Scrap Shaker Product Details

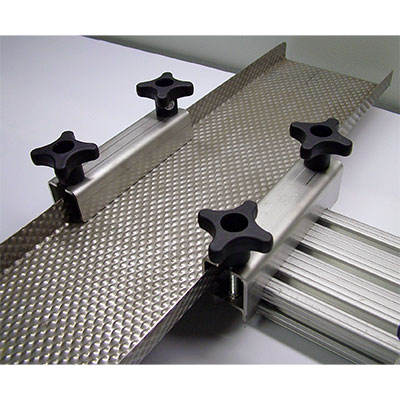

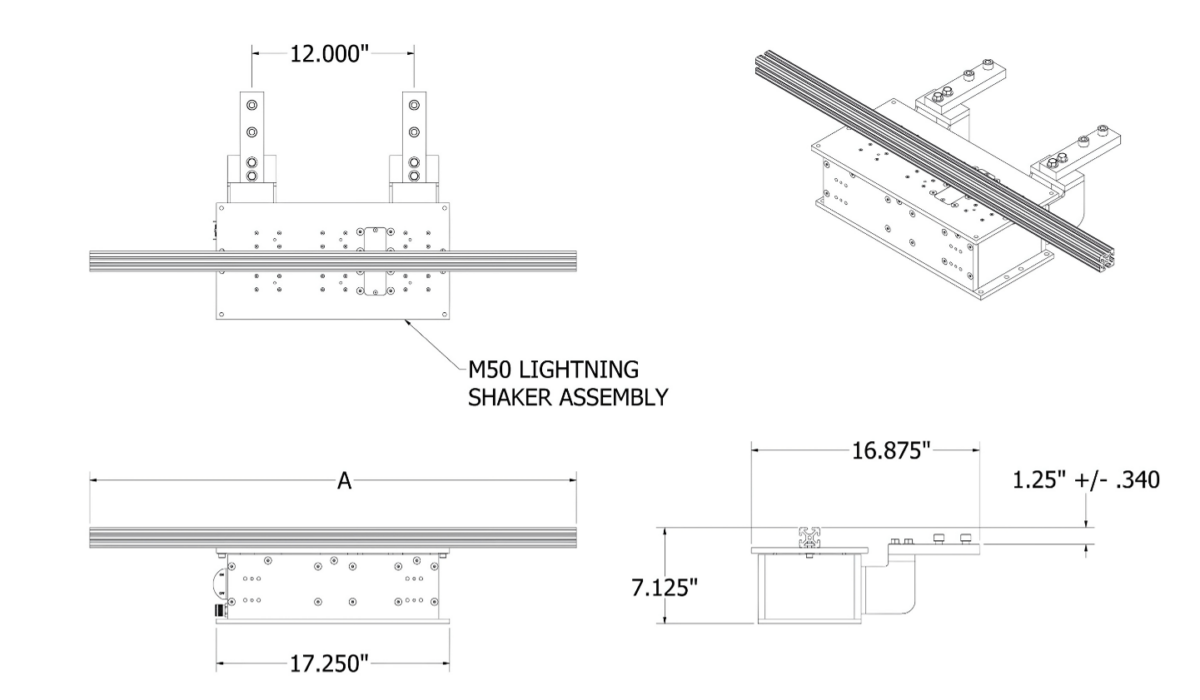

The M Series press-mounted scrap conveyor effectively transports scrap metal using our patented electric shaker motor, which drives metal pans. This motor generates a slow, low-frequency movement with a quick return, propelling stamping scrap forward. It is affixed to the bolster via one or more T-slot mounts that fit into standard T-slots. Once positioned, the tongue can be tightened to securely attach the scrap system’s motor to the bolster.

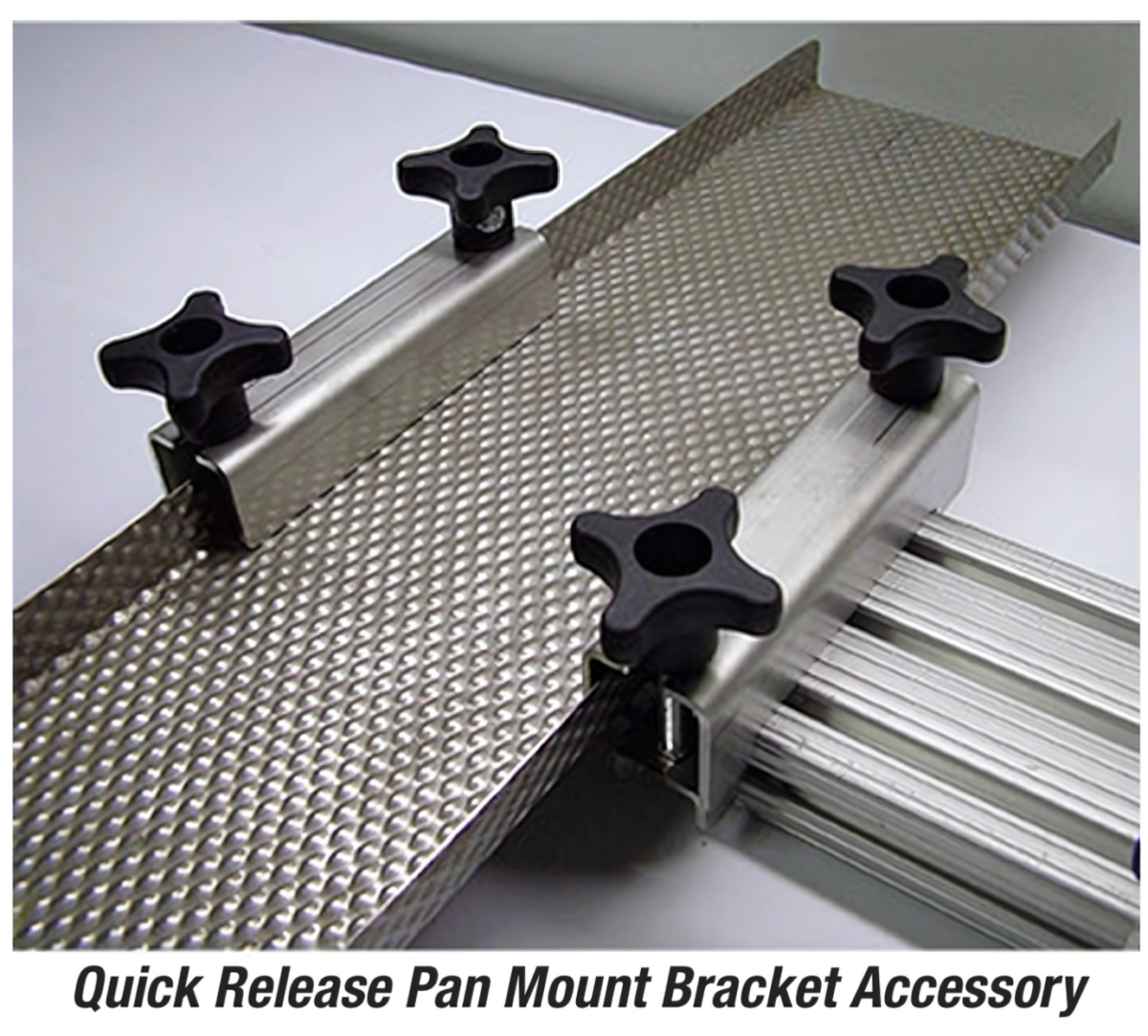

A crossbar made of extruded aluminum is fixed to the top plate of the electric shaker conveyor, oriented perpendicular to the movement of parts. This crossbar allows operators to attach a metal pan for scrap conveyance using a Quick Release Pan Mount Bracket Accessory set, with one set needed for each pan. Once mounted, the pan can slide forward and backward within the brackets and left and right on the crossbar to accurately position it between the die's uprights where scrap will accumulate. After positioning, the metal pans can be hand-tightened to lock them in place during press operation.

Multiple pans of various sizes can be attached to a single crossbar depending on the die setup. MPI recommends maintaining a balanced load across the width of the crossbar for the M-10 and M-50 scrap removal systems, while the M-200 Rack and Pinion System does not necessitate an even load.

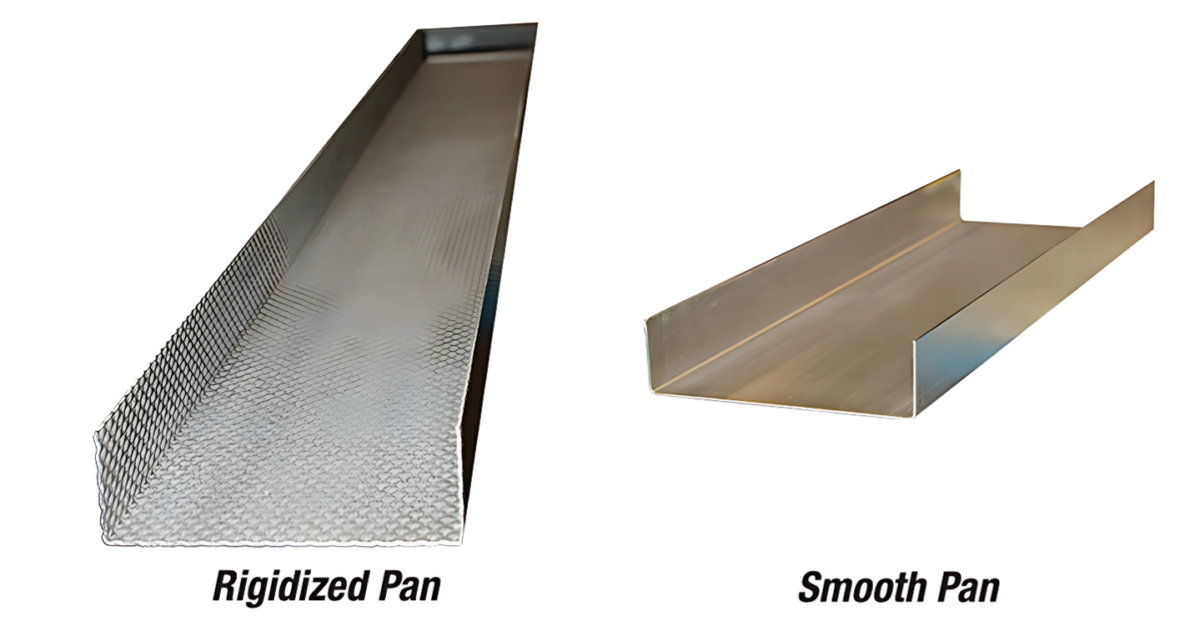

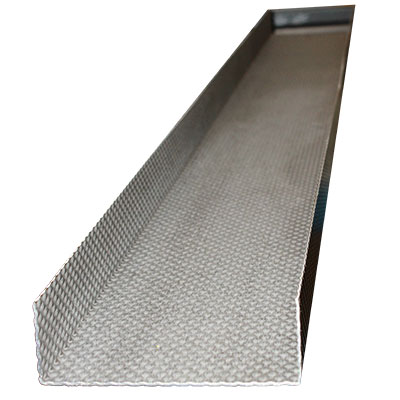

Shaker pans can be produced by MPI or by the customer, utilizing any steel construction type. Rigidized pans are particularly beneficial for oil-heavy applications as they assist in breaking surface tension for part movement. They can be fabricated in any required shape or size to effectively capture all scrap from the die. Typically, the pan width aligns with the distance between uprights, allowing a slight margin for clearance, and the side height ranges from 1-2 inches. When installing the shaker conveyor, ensure the top of the crossbar is level with the bolster height, allowing the attached pan to be supported by the bolster.

With the scrap removal conveyor set up, it is ready to be powered on. A manual switch on the electric shaker activates the unit. Alternatively, operators can choose to operate it remotely by keeping the shaker motor powered and adding a switch near the press controls or incorporating it with the controls.

The scrap handling equipment functions almost silently and utilizes a high-efficiency motor to minimize operating costs. Compared to pneumatic scrap shaker designs, MPI electric scrap shakers can reduce operating expenses by up to 71% and require no maintenance. It is engineered to convey scrap metal at 20 feet per minute effectively.

The MPI M-50 Electric Scrap Shaker Conveyor is often integrated with a Steel Belt Conveyor, Beltless Magnetic Conveyor, or underground scrap shaker, forming a comprehensive scrap handling system.

-

Mounting and Setup

The M-50 unit is installed beneath multiple press stations, punch machines, or robotic cells and linked to one or more scrap trays.

-

Electric Activation

An electric control system powers the shaker, allowing for continuous operation or synchronization with press cycles.

-

Vibratory Motion Initiation

The linear mechanical drive produces strong, consistent vibratory motion, facilitating the movement of scrap along tray paths.

-

Material Conveyance

Scrap metal pieces slide forward on the tray's surface, directed by vibrations toward a central discharge area.

-

Scrap Collection

Scrap is collected into bins, carts, or transfer conveyors at the end of the tray path.

-

Continuous, Automated Removal

The M-50 operates throughout production, ensuring the scrap path remains clear without operator intervention.

M-50 Electric Scrap Shaker Specification Table

US Customary Units

| MODEL FEATURE | M-50 Motor Only | M-50 System |

|---|---|---|

| Power Input | 110 VAC, single phase | 110 VAC, single phase |

| System Weight | 45 lbs. | 53 lbs. |

| Design Capacity (Pans and Scrap) | 50 lbs. | 50 lbs. |

| Crossbar Width Included | Not Included | 36 in. |

| T-Slot Sizes Included | Not Included | 0.50″ Thick x 1.375″ Wide and 3/4″ thick x 1.75″ Wide |

| Quick Release Pan Mount Bracket Accessory | Not Included | Not Included |

M-50 Electric Scrap Shaker Installations & Variations

M-50 Shaker for Multi-Press and Progressive Stamping Lines

M-50 Shaker Scrap-Intensive Fabrication Environment

M-50 Shaker for Large Die-Cutting, Punching, and Trimming Operation