Achieve Industry-Leading Separation Rates

MPI's Patented Commingled Sorting Systems are engineered to deliver high-efficiency separation of mixed recyclable materials, optimizing the recovery of valuable commodities while reducing contamination. Tailored for material recovery facilities (MRFs), waste management operations, and industrial recycling plants, these systems utilize cutting-edge magnetic, eddy current, and sensor-based technologies to effectively sort and recover ferrous and non-ferrous metals, plastics, paper, and other essential materials from mixed waste streams. MPI’s patented Commingled Sorting System is adept at achieving industry-leading separation rates on highly commingled materials that require ferrous metal reclamation. Typical applications include tire recycling, municipal solid waste, crushed batteries, and brake pad compounds.

Benefits of the Commingled Sorting From Magnetic Products, Inc

-

High-Strength Magnetic Circuit

Equipped with rare-earth or ceramic magnets for varying contamination levels. Superior Contaminant Removal – captures ferrous and paramagnetic particles, even at sub-micron levels, ensuring cleaner fluids.

-

Multi-Stage Separation for Maximum Recovery

Ferrous Metal Removal: Powerful permanent and electromagnetic separators extract steel and iron-based materials early in the sorting process. Non-Ferrous Metal Recovery: aluminum, brass, and copper, ensuring high-value metal recovery. Optical & Sensor-Based Sorting: Smart detection systems identify and separate plastics, paper, and other materials with precision.

-

Customizable System Configurations

Designed for single-stream, dual-stream, and commingled recycling applications. Modular design allows for integration with existing MRFs or fully automated new installations. Available in various throughput capacities to match operational requirements.

-

Durable & Low-Maintenance Construction

Heavy-duty, industrial-grade components provide long-term durability in high-volume environments. Advanced self-cleaning features on magnetic and eddy current separators reduce downtime and maintenance costs.

-

Sustainable & Cost-Effective Recycling Solutions

Enhances the value and marketability of recovered materials. Reduces landfill waste and promotes eco-friendly processing. Lowers overall operational costs through automated sorting.

-

Increased Processing Efficiency & Throughput

Reduces manual sorting labor while improving material purity. High-speed conveyors and separation technologies optimize material flow, boosting overall processing efficiency. Ensures compliance with industry quality standards for recyclables.

Commingled Sorting Product Details

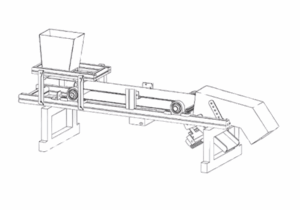

How the Commingled Sorting System Works

The Commingled Sorting System is designed to efficiently separate ferrous metals from non-ferrous materials in a mixed product stream. The system ensures precise sorting through a combination of mechanical and magnetic processes.

The Commingled Sorting System is a highly efficient solution for separating ferrous and non-ferrous metals. By using a combination of vibratory feeding, magnetic agitation, and optional advanced separation technology, the system ensures that metals are properly sorted and collected, optimizing recycling and material recovery processes.

Feeding the Mixed Material

The process begins when a hopper receives the mixed product that contains ferrous metal. The hopper directs the material onto a vibratory conveyor, which ensures an even distribution of the product as it moves toward the main conveyor belt. This uniform spread is critical for consistent sorting efficiency.

Initial Separation Using Magnetic Rail

As the material moves along the main conveyor belt, a magnetic rail is positioned above it, running along its entire length. The magnetic rail is equipped with an additional moving conveyor belt that travels across its working surface.

The magnetic rail moves back and forth, sweeping across the width of the belt. This movement is key to:

- Capturing and holding ferrous metals (such as iron and steel) as they travel along the main conveyor.

- Agitating the captured metal to release any non-ferrous materials that may have been loosely attached or trapped within the ferrous material.

By continuously moving and agitating the metal, the system effectively separates different material types.

Sorting Ferrous and Non-Ferrous Metals

The ferrous metals remain magnetically attached as they travel further down the conveyor system. Eventually, they reach a designated release point where they are dropped into a separate collection bin.

Meanwhile, the non-ferrous materials (such as aluminum, copper, and other metals that do not respond to magnets) continue along the conveyor belt and are deposited separately.

Enhanced Magnetic Separation (Optional Upgrade)

For more precise separation, especially when dealing with some grades of stainless steel and other weakly magnetic materials, the system can be enhanced with an MPI Arch Technology Magnetic Head Pulley at the discharge point of the non-ferrous conveyor.

This additional magnetic component:

- Captures and removes stainless steel and other weakly magnetic materials that may have remained with the non-ferrous stream.

- Further increases the purity and efficiency of the sorting process.

Commingled Sorting Specification Table

These system is built specifically for each application; contact our Customer Service Department to plan your turn-key system today.

Commingled Sorting Installations & Variations

Custom Commingled Sorting System for Copper Processing Application

Custom Commingled Sorting System Designed for Metal Reclaim in Plastics Processing

Custom Waste Management & Recycling Commingled Sorting System