24/7 Lights Out Conveyance Solution

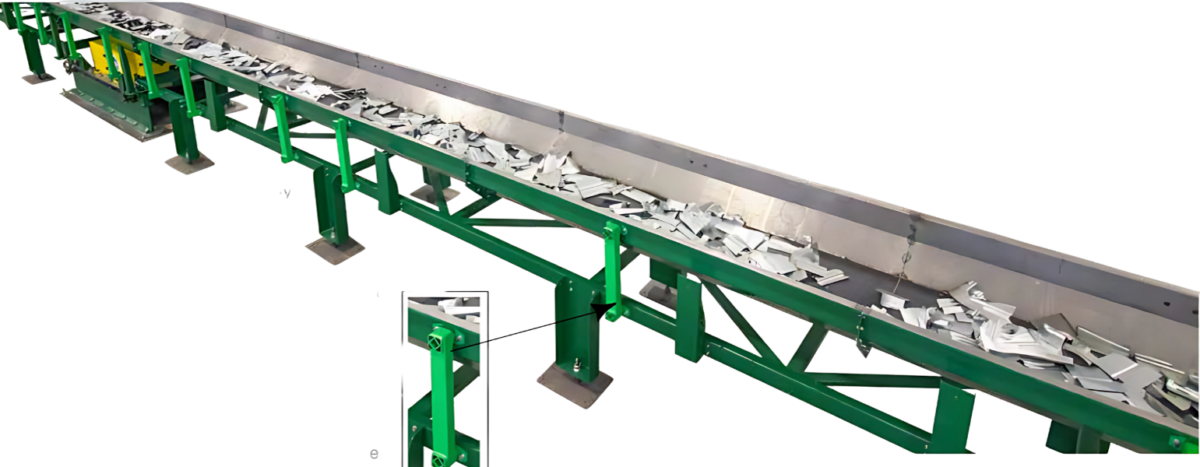

The M-10000 Series High-Capacity Floor Mounted Electric Shaker Conveyor by MPI is engineered to efficiently transfer scrap metal, bulk products, or various materials over extended horizontal distances. This conveyor system is capable of handling transfer rates exceeding 10,000 pounds per hour and distances reaching hundreds of feet. It features a formed steel pan powered by a single drive, operating at a smooth, low frequency to ensure materials are conveyed in a horizontal motion.

This robust shaker conveyor is suitable for demanding applications, including scrap removal conveyors, press scrap conveyors, and scrap removal systems, effectively handling even the most abrasive materials such as scrap metal, castings, and rocks. Despite its ruggedness, the shaker conveyor operates gently enough to transport delicate items, such as potato chips, nuts, or biscuits, without causing breakage.

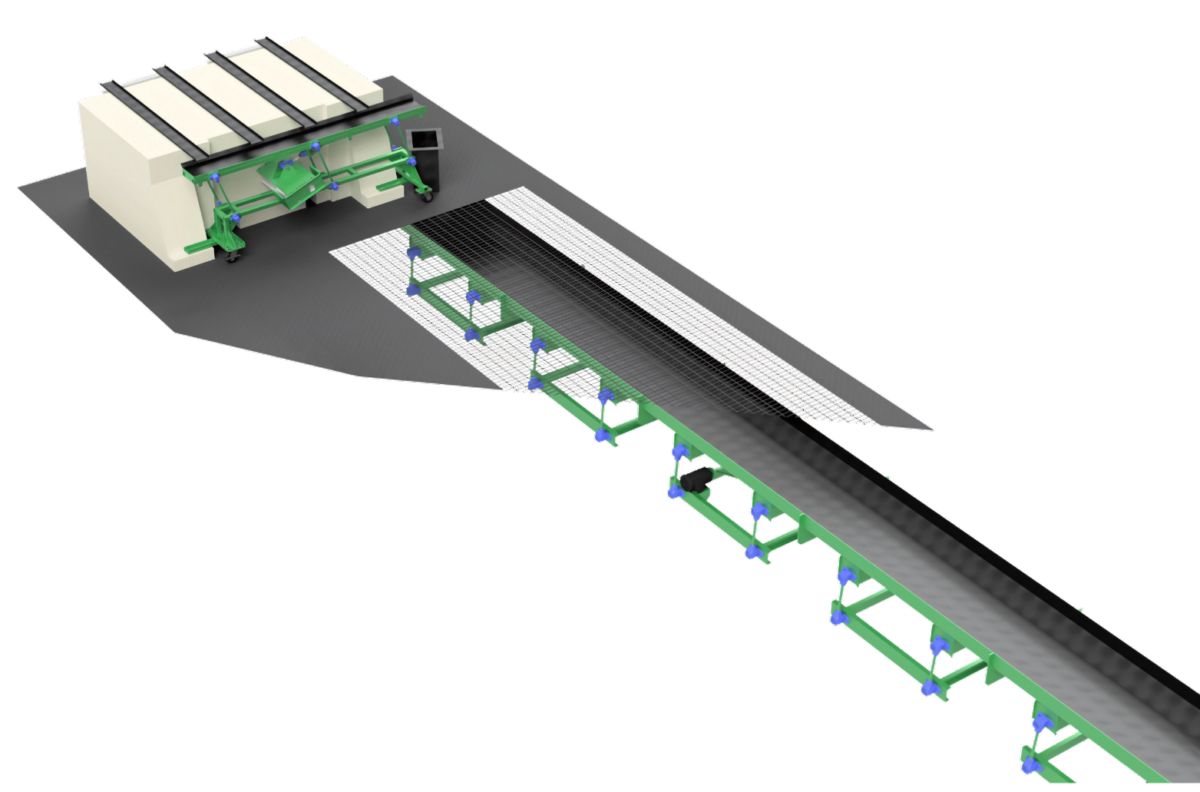

The M-10000 Series is frequently incorporated into comprehensive turnkey systems that include additional components like incline conveyors, horizontal motion conveyors, and control systems. In the stamping sector, these conveyors are integral to underground scrap systems or centralized scrap handling systems, facilitating the collection and transfer of scrap metal from stamping presses.

Benefits of the M-10000 Electric Scrap Shaker From Magnetic Products, Inc

-

Powerful Linear Drive Motor

Provides high-force, low-noise performance without the need for compressed air or complex pneumatics.

-

Medium-Heavy Capacity

Optimized to handle higher scrap loads and longer conveying distances than smaller models, ideal for progressive die applications.

-

Maintenance-Free Operation

No belts, bearings, or internal moving parts to replace, drastically reducing upkeep and unplanned downtime.

-

Compact, Versatile Mounting

Can be mounted under or alongside conveyors, dies, or presses, making it suitable for tight footprints.

-

24/7 Operation-Ready

Built to withstand high-frequency scrap ejection processes with continuous-duty cycle capability.

-

Programmable Frequency and Stroke

Adjust settings to optimize scrap movement for various materials and scrap geometries.

-

Robust Housing and Seals

Designed for industrial durability, dust and fluid ingress resistance, and long service life in harsh conditions.

-

Energy Efficient

Electric drive uses significantly less energy than traditional pneumatic shaker systems, lowering operational costs.

M-10000 Electric Scrap Shaker Product Details

The MPI M-10000 horizontal motion conveyor uses modular sections of pans assembled to form a continuous single pan. It is driven by a single section with a drive connected to the pan above. This drive creates a slow, low-frequency movement with a quick return that drives material forward. Utilizing a single continuously formed pan assembly ensures the scrap metal is contained while eliminating jams caused by pinch points.

The shaker pans are supported by maintenance-free Rubber Suspension Technology (RST) bearings. Unlike traditional bearings, RST bearings use pressed rubber around a square shaft, which requires no grease. This gives the bearing several functions, including a torsion spring, pivot bearing, and anti-vibration mount. The design also eliminates metal-on-metal contact points, which are friction locations known to create wear or maintenance issues.

The drive is a scaled-up design from MPI’s trusted and patented M Series shaker conveyor line. The shaker system operates almost silently and uses a high-efficiency motor to reduce operating costs. It is designed to transfer materials at a rate of up to 15 FPM.

The M-10000 series horizontal motion conveyor is different from traditional fiber leaf spring vibratory conveyors or electromagnetic vibratory conveyors, which vibrate products at a high frequency. MPI’s horizontal motion conveyor moves the product using a low-frequency, smooth motion.

Step-by-Step

Installation

The M-1000 is mounted directly to the scrap pan or conveying chute of a stamping press or processing line.

Activation

When the press begins operation, the M-1000 receives a signal and activates its linear electromagnetic drive.

Linear Motion Begins

The internal coil and magnets generate rapid back-and-forth motion, shaking the scrap pan in a controlled oscillation.

Scrap Propulsion

Vibratory motion propels scrap horizontally along the pan toward collection points or bins.

Adjustable Settings

Operators can fine-tune the stroke and frequency to match scrap type, size, and volume.

Continuous Operation

The system runs in tandem with press cycles, efficiently removing scrap without manual intervention.

Typical Applications

-

Progressive Die Stamping

Efficiently evacuates punch-outs, trims, slugs, and other scrap from high-speed stamping presses.

-

Blanking and Forming Operations

Moves sharp or irregular metal scrap away from dies and tooling areas to prevent buildup and downtime.

-

Press Room Scrap Removal

Automates scrap handling across multiple presses, minimizing manual handling and improving operator safety.

-

Laser Cutting & CNC Punching Cells

Clears metal shavings and cutouts from automated cutting lines to keep operations clean and uninterrupted.

-

Metal Fabrication Facilities

Transports scrap metal from fabrication stations to bins, compactors, or recycling areas.

-

Automotive Parts Manufacturing

Supports production lines with frequent scrap generation from chassis, structural, or body panel fabrication.

-

Transfer Line Integration

Integrates into conveyor systems under transfer presses or robotic arms for automated scrap transfer.

M-10000 Electric Scrap Shaker Specifications

M-10000 Electric Scrap Shaker Installations & Variations

M-1000 Electric Scrap Shaker Conveyor Installed in Progressive Die Stamping Facility

M-1000 Electric Scrap Shaker Conveyor Installed in Transfer Line Integration

M-1000 Electric Scrap Shaker Conveyor for Automotive Parts Manufacturing