Easy Integration Into Your Production Line

A Metal Detector identifies contaminants with a conductive quality (electrical conductivity or electrical signal) differing from that of the product being processed. A Metal Detector reads the “signature” electronic signal of the conductivity of a product as it flows through a process. Each product is cataloged as a specific “recipe” of components. If the Metal Detector senses something that falls outside of its programmed recipe, an alarm is triggered. This tells the operator that a foreign object is contained in that product. The contaminated product can then be removed and investigated.

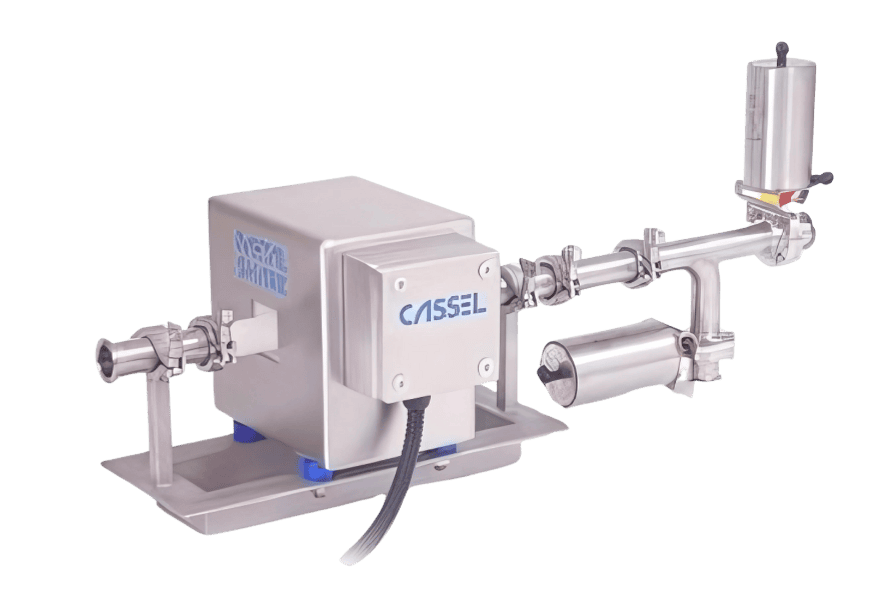

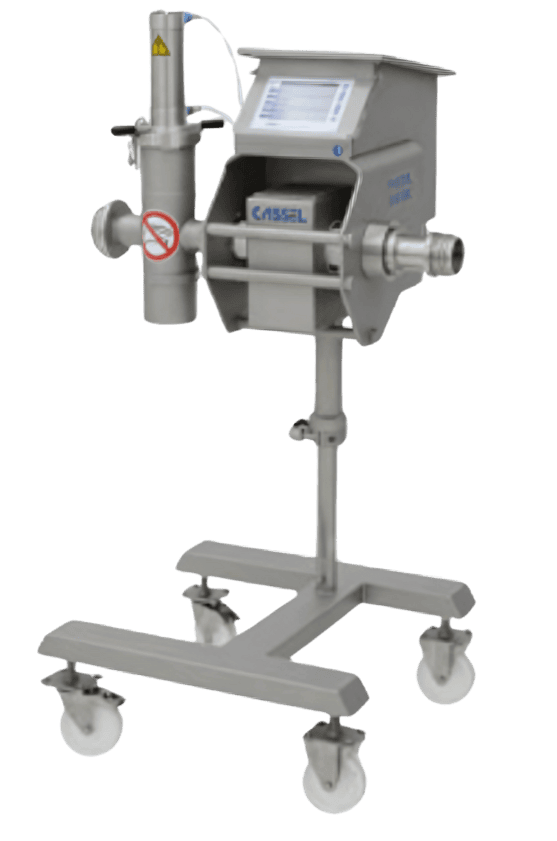

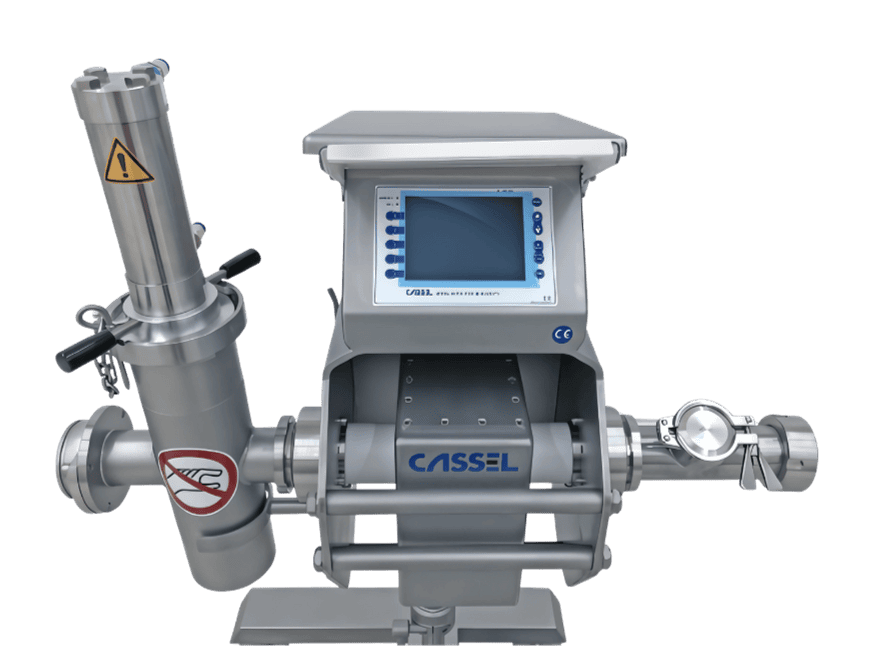

Cassel’s “IN MEAT” compact Metal Detector is designed for sausage stuffers and is easily transportable via its wheeled base. An integrated gas spring provides quick height adjustment (33.5” - 47.2”), allowing installation between the stuffer and clip machines. Links and adapters are available for nearly every type of stuffer and clip machine. A variety of reject systems are offered.

Benefits of the Meat Metal Detector From Magnetic Products, Inc

-

HACCP and IFS Compliance

Per HACCP principles, Metal Detectors are classified as critical control points and continuous checking is required to meet standards. If requested, Cassel can add a performance validation system (PVS) which automatically prompts the operator to test Metal Detector performance at pre-set intervals.

-

Operational History

Metal contaminant event or history, metal report, changes in parameter settings and other events are recorded with the date and time. Users can view the list of “incidents” on the control panel or export the log.

-

SHARKNET® Software Ready

To comply with HACCP and IFS standards, SHARKNET® enables automatic downloading of data documentation to a Windows-based PC.

-

LPW Option for Low Pressure Wash-Down

To obtain the IP67 rating, the METAL SHARK® controller can be housed in a double thick stainless steel enclosure. This upgrade allow for wash down with a pressure hose.

-

HPW Option for High Pressure Wash-Down

To obtain the IP69k rating, the aperture can be specially sealed to prevent leaks, and the METAL SHARK® controller can be housed in a double-thick stainless-steel enclosure. Daily wash-ups with a steam hose at a maximum pressure of 60 bar/900 psi can be conducted. Sausage processors as well as other manufacturers who conduct frequent wash-ups have found this feature very beneficial.

-

Sturdy Frame

The hygienic design is easy to clean. All rods are completely welded on all sides. Due to an integrated gas spring, height adjustment is easy for one operator to handle. Four casters make it comfortable to move the metal detector.

-

Plug-In Ready

The external device cables are plugged in between the filling and the clipping machine. Compatible plug and socket are provided with the type of filling machine.

-

Easy To Clean

Due to the hygienic design the metal detector can easily be disassembled for daily rinsing with water or steam hose cleaning.

Meat Metal Detector Product Details

Compact metal detector for sausage pumps and stuffer machines. Mobile base frame, stand with integrated gas spring for easy height adjustment 850 – 1200 mm (33.5 – 47.2″), for installation between stuffer and clip machine. Includes connection cable with external device plug and socket. Integration of the In Meat Metal Detector into your production line is easy.

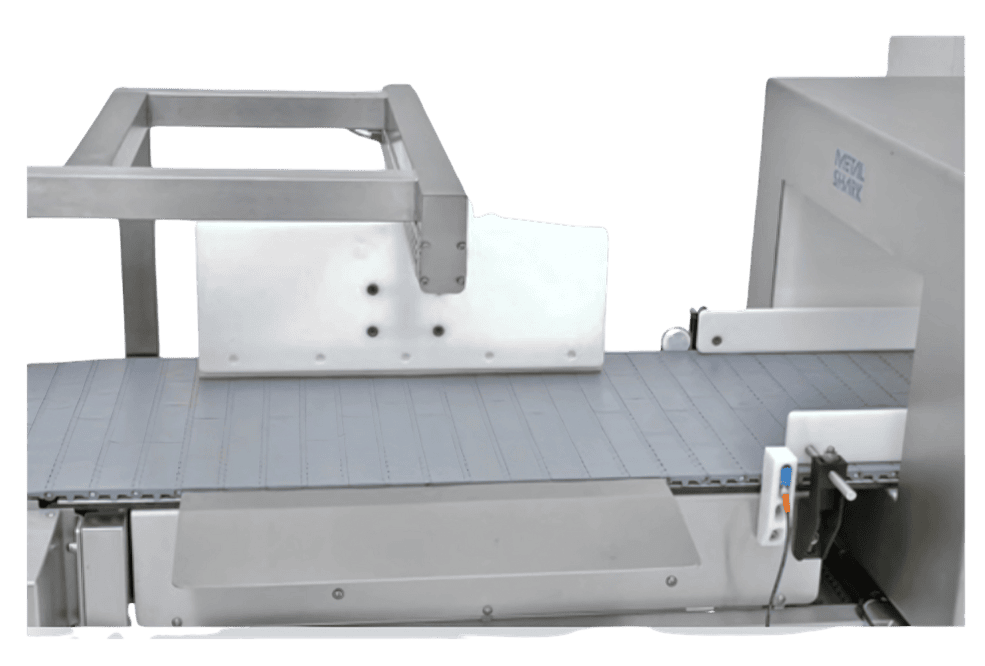

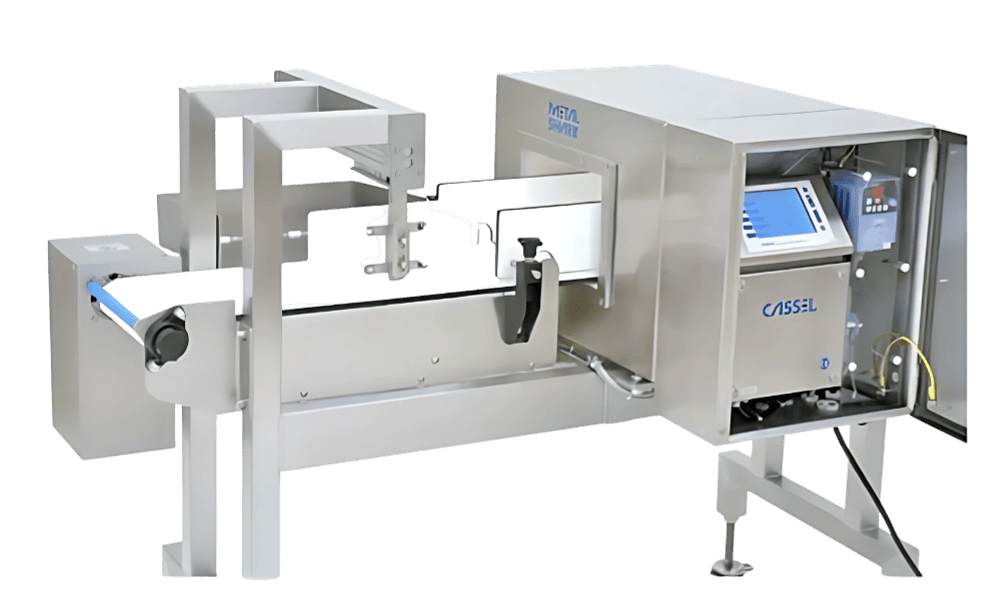

- The Cassel’s METAL SHARK® BD Metal Detector is often used to detect contaminants

in meat, poultry and seafood. Typically integrated onto a conveyor belt, the METAL

SHARK® BD readily adjusts settings to ensure extreme equipment sensitivity, stability and reliability. A variety of reject mechanisms (pusher, belt stop and alarm, etc.) are available to alert operators of a “find” or to divert contaminated product. The conveyor belt, framing and controls are available in sanitary design for food grade process applications. Cassel Metal Detectors can be easily adjusted to accommodate multi-system processing and environmental changes. - As raw materials arrive in the processing area, they must be examined for metal contaminants (5 -10 mm) such as knife blades, metal gloves, meat etc. Typically, a metal detection system comprised of a conveyor-style metal detector with an upgraded HW conveyor, and LPW or HPW option would be selected. The HW conveyor features an open stainless frame without dirt traps, a waterproof stainless drum motor, fully encapsulated sensor head and an FDA/USDA-approved transfer belt.

- A Conveyor-style Metal Detector with upgraded high-pressure wash down conveyor would generally be installed after product passes through the roll stock machine. Cassel offers a special flapping roller table that moves contaminated product to a specified area without shutting down production.

- A Conveyor-style Metal Detector with upgraded HW conveyor would generally be installed on the

production line after product passes through the roll stock machine. Cassel offers a special flapping roller table that moves contaminated product to a specified area without shutting down the Metal Detector. - Cassel offers a variety of customized solutions for special applications such as an oversized Metal Detector designed for shredding large pieces of pork. Cassel can also provide automatic product selection to adjust for product height. This is especially useful for fresh meat packaged in styrofoam trays which traditionally requires that the Metal Detector be set to accommodate the largest package. The Cassel option allows the Metal Detector to adjust to various product sizes, which means that sensitivity remains consistent.

Meat Metal Detector Installations & Variations

Metal Detector For Meat Integrated onto Conveyor Belt at Critical Metal Contamination Check Point

Metal Detector For Sausage and Processed Meat Applications