Product Information Coming Soon

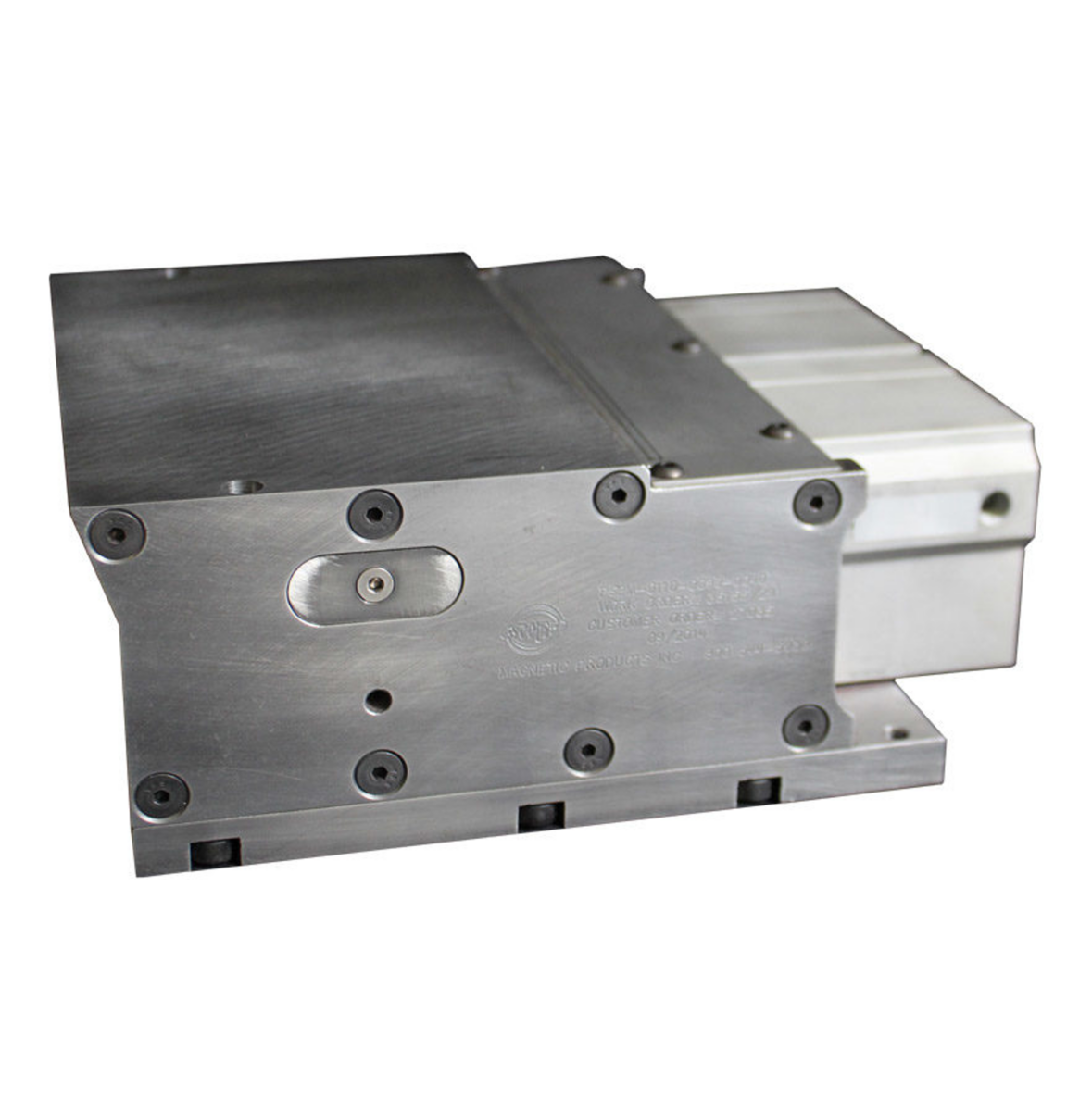

Pneumatic Switchable Permanent Magnet

Benefits of the Pneumatic Switchable Permanent Magnet (PSPM) From Magnetic Products, Inc

-

Benefits Coming Soon

-

Coming Soon

Pneumatic Switchable Permanent Magnet (PSPM) Product Details

How It Works

Product Options

Related Resources and Technical Information

Pneumatic Switchable Permanent Magnet (PSPM) Specification Table

US Customary Units

Compatibility Check - Pneumatic Switchable Permanent Magnet (PSPM) Installations

Company Name Application information

Company Name Application information

Company Name Application information