Trouble-Free Automatic Extraction of Tramp Iron

Magnetic Products Inc. (MPI) Drum Separators are engineered to eliminate ferrous contaminants from bulk material flows in high-capacity industrial operations. These separators utilize a rotating drum that effectively captures and segregates metal impurities from product streams, ensuring product integrity and safeguarding downstream equipment. They are particularly well-suited for sectors such as mining, recycling, food processing, and manufacturing, where MPI Drum Separators provide dependable performance under demanding conditions. MPI’s Magnetic Drum Separator and Housing are specifically designed for the seamless automatic extraction of tramp iron from heavy flows of large and abrasive materials like coal, aggregates, ores, sugarcane, and wheat. As the product stream engages with the drum magnet, the formidable permanent magnetic field reaches out and retains ferrous particles on the rotating shell.

Benefits of the Drum Separator From Magnetic Products, Inc

-

High-Intensity Magnetic Circuit

MPI’s Drum Separator is engineered with a robust, high-intensity magnetic circuit that delivers superior separation performance. This advanced magnetic system efficiently captures ferrous contaminants—large tramp metal and fine particulates—from product flow. The result is cleaner output, improved product purity, and enhanced protection for downstream equipment, reducing maintenance costs and preventing potential damage.

-

Rotating Drum Design

The rotating drum enables continuous, automated separation of ferrous materials without manual intervention. As material flows over the magnetic drum, ferrous particles are attracted and held to the drum’s surface before being discharged into a separate collection area. This design allows uninterrupted processing and maximizes productivity in high-volume and batch-processing operations.

-

Durable Construction

Built to withstand the rigors of demanding industrial environments, the Drum Separator features heavy-duty stainless-steel housing and components. This corrosion-resistant construction ensures long-lasting performance and reliability, even when handling abrasive or moist materials. It is ideal for mining, recycling, chemical, and food processing applications.

-

Customizable Configurations

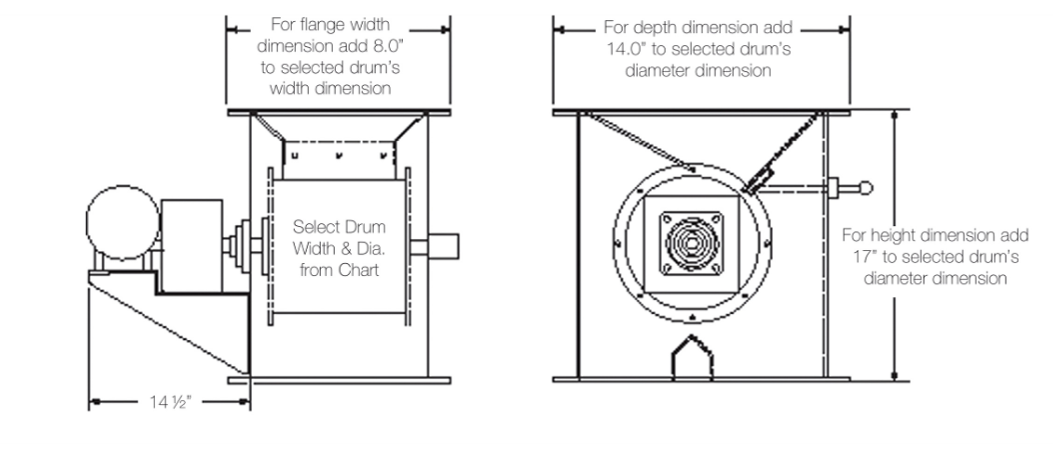

Recognizing that every process is unique, MPI offers fully customizable Drum Separator configurations. Options include various drum sizes, magnetic strengths, motor types, and discharge setups. These tailored solutions ensure optimal performance based on your specific material characteristics, flow rates, and separation goals—whether you're removing ferrous from powders, granules, or bulk solids.

-

Energy Efficient

Designed with operational efficiency in mind, MPI’s Drum Separator delivers high-performance magnetic separation with low power consumption. The energy-efficient motor system reduces operating costs and supports sustainable processing practices without sacrificing throughput or effectiveness.

-

Food-Grade Options

MPI offers food-grade Drum Separators built with FDA-compliant materials and sanitary finishes for applications requiring strict hygiene standards. These models are ideal for food, pharmaceutical, and nutraceutical industries, where contamination control and cleanliness are paramount. The design also supports easy disassembly and cleaning to meet rigorous sanitation protocols.

Drum Separator Product Details

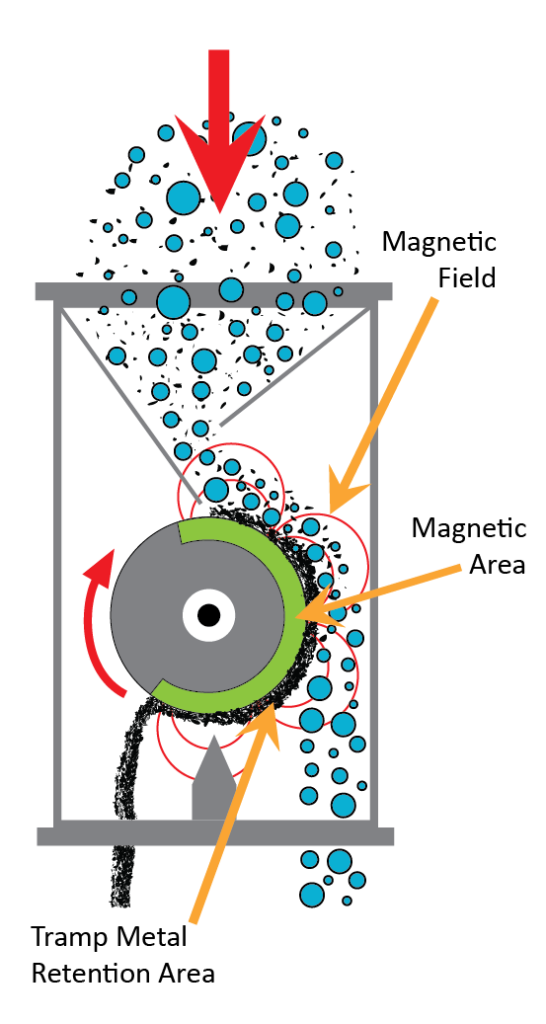

MPI’s Drum Separator is designed for efficient, continuous separation of ferrous contaminants from dry, free-flowing product streams. The system operates using a high-intensity permanent magnetic field housed within a rotating drum shell. Here's how the process works in detail:

As the material is introduced to the infeed area, it flows across the rotating drum's surface. A robust internal magnetic circuit generates a deep-reaching magnetic field that penetrates the product stream. As the drum turns, ferrous particles—such as tramp iron, steel fragments, and fine metal shavings—are immediately attracted to and held firmly against the rotating shell's surface.

The drum's rotation carries these captured ferrous contaminants away from the clean product stream, maintaining constant contact with the magnetic field to ensure no particles are lost or re-entrained. As the drum rotates, ferrous materials are transported past a strategically positioned divider. Once the drum surface moves out of the magnetic field’s influence, the magnetic hold is released, allowing the ferrous contaminants to drop off cleanly into a dedicated tramp metal discharge chute or collection bin.

Meanwhile, non-magnetic materials are unaffected by the magnetic field and continue flowing downstream, uninterrupted and contamination-free. This process ensures continuous operation without stopping for cleaning or batch processing, which significantly increases throughput and system efficiency.

The DSH-Series Drum Separators are available in a range of standard diameters and configurations to accommodate various throughput rates, material types, and installation environments. Whether integrated into existing process lines or installed as standalone units, MPI Drum

Separators offer reliable, automated ferrous

removal with minimal maintenance.

Drum Separator Specification Table

US Customary Units

| DRUM SEPARATOR MODEL # | DRUM WIDTH (IN.) | DRUM DIAMETER (IN.) | CAPACITY (IN.) FT³/HR |

|---|---|---|---|

| DS-12/45 | 12″ Drum 45 RPM | 12 | 1000 |

| DS-14/45 | 12″ Drum 45 RPM | 14 | 1200 |

| DS-16/45 | 12″ Drum 45 RPM | 16 | 1400 |

| DS-18/45 | 12″ Drum 45 RPM | 20 | 1800 |

| DS-30/45 | 12″ Drum 45 RPM | 30 | 2800 |

| DS-36/45 | 12″ Drum 45 RPM | 36 | 3300 |

| DS-42/45 | 12″ Drum 45 RPM | 42 | 3900 |

| DS-12/35 | 18″ Drum 35 RPM | 12 | 1600 |

| DS-14/35 | 18″ Drum 35 RPM | 14 | 1900 |

| DS-16/35 | 18″ Drum 35 RPM | 16 | 2200 |

| DS-18/35 | 18″ Drum 35 RPM | 18 | 2500 |

| DS-20/35 | 18″ Drum 35 RPM | 20 | 2800 |

| DS-24/35 | 18″ Drum 35 RPM | 24 | 3400 |

| DS-30/35 | 18″ Drum 35 RPM | 30 | 4300 |

| DS-36/35 | 18″ Drum 35 RPM | 36 | 5200 |

| DS-42/35 | 18″ Drum 35 RPM | 42 | 6100 |

| DS-48/35 | 18″ Drum 35 RPM | 48 | 7000 |

| DS-18/30 | 24″ Drum 30 RPM | 18 | 3700 |

| DS-20/30 | 24″ Drum 30 RPM | 20 | 4200 |

| DS-24/30 | 24″ Drum 30 RPM | 24 | 5100 |

| DS-30/30 | 24″ Drum 30 RPM | 30 | 6500 |

| DS-36/30 | 24″ Drum 30 RPM | 36 | 7800 |

| DS-42/30 | 24″ Drum 30 RPM | 42 | 9200 |

| DS-48/30 | 24″ Drum 30 RPM | 48 | 10500 |

| DS-54/30 | 24″ Drum 30 RPM | 54 | 11900 |

| DS-60/30 | 24″ Drum 30 RPM | 60 | 13200 |

| DS-24/25 | 30″ Drum 25 RPM | 24 | 7200 |

| DS-30/25 | 30″ Drum 25 RPM | 30 | 9200 |

| DS-36/25 | 30″ Drum 25 RPM | 36 | 11100 |

| DS-42/25 | 30″ Drum 25 RPM | 42 | 13000 |

| DS-48/25 | 30″ Drum 25 RPM | 48 | 14900 |

| DS-54/25 | 30″ Drum 25 RPM | 54 | 16800 |

| DS-60/25 | 30″ Drum 25 RPM | 60 | 18700 |

| DS-24/20 | 36″ Drum 20 RPM | 24 | 9800 |

| DS-30/20 | 36″ Drum 20 RPM | 30 | 12500 |

| DS-36/20 | 36″ Drum 20 RPM | 36 | 15200 |

| DS-42/30 | 36″ Drum 20 RPM | 42 | 17800 |

| DS-48/20 | 36″ Drum 20 RPM | 48 | 20400 |

| DS-54/20 | 36″ Drum 20 RPM | 54 | 23000 |

| DS-60/20 | 36″ Drum 20 RPM | 60 | 25600 |

Drum Separator Installations & Variations

Magnetic Drum Separator Designed for Sorting Crumb Rubber

Custom Drum Separator for Tire Recycling

Large Magnetic Drum Separator for Municipal Waste Management & Recycling