State-of-the-Art System Controls and Features

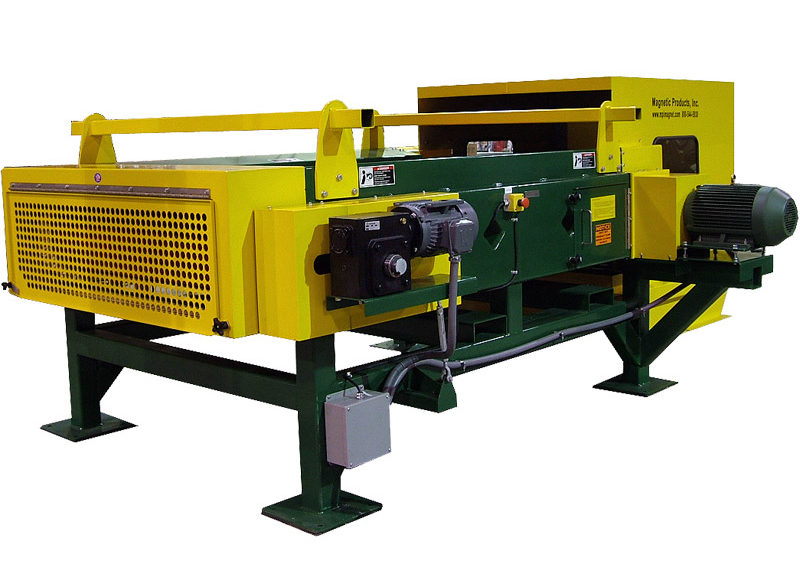

Eddy Current Separators effectively extract nonferrous metals like aluminum, die-cast metals, and copper from nonmetallic materials. MPI’s established eddy current technology guarantees enhanced separation efficiency. The integration of advanced system controls and features, along with innovative technological developments, leads to better removal of nonferrous metals, especially when separating smaller particles such as aluminum and brass from non-conductive waste streams.

Eddy Current Separators (ECS) can be utilized in any scenario where the recovery or segregation of nonferrous metals is required. Typical applications include processing of trash and municipal waste, auto shredding, sorting of beverage cans, recovery of glass and foundry sand, recycling of windows, plastic materials, and scrap wood.

Benefits of the Eddy Current Separator From Magnetic Products, Inc

-

High-Speed Rare Earth Rotor Design

Delivers superior separation of non-ferrous metals (like aluminum and copper) from bulk material streams, increasing recovery rates and operational efficiency.

-

Adjustable Splitter & Belt Speed Control

Fine-tunes material trajectories for optimal metal recovery, allowing operators to adapt separation performance to various material types and processing goals.

-

Heavy-Duty, Low-Maintenance Construction

Built for durability in harsh recycling and material handling environments, reducing downtime and maintenance costs over time.

-

Vulcanized Rubber, High-Friction Conveyor Belt

It ensures stable material transport and improved ejection accuracy, which is especially critical when dealing with smaller or lightweight metal pieces.

-

Self-Cleaning Operation

Continuous automatic separation means fewer manual interventions, enhancing throughput and operator safety.

-

Integrated Controls and Safety Features

Simplifies integration with plant systems and prioritizes operator protection through intuitive interface and built-in fail-safes.

-

Magnetic Rotor Enclosure with Thermal Isolation

Extends rotor life and prevents overheating during extended operations, ensuring consistent performance.

-

Modular Design Options

Enables flexible installation either as a standalone system or integrated into a broader material handling line, accommodating a wide range of applications.

Eddy Current Separator Product Details

The MPI Eddy Current Separator (ECS) is engineered to separate non-ferrous metals from a conveyed material stream using a powerful, rotating magnetic field. Commingled material is fed onto the conveyor belt of the eddy current separator. The material is conveyed over a spinning magnetic rotor where separation occurs. The two streams of material discharge over and away from the separator. The main component of MPI’s Eddy Current Separator (ECS Series) is the magnetic rotor, which uses a series of permanent Rare Earth magnets mounted to a plate that, in turn, is attached to the motor-driven shaft. These magnets are covered by a fiberglass shell with ceramic tiles that reduce wear and allow the conveyor belt to ride over them. The magnetic rotor spins independently and at a much faster rate than the conveyor belt pulley. When a product such as aluminum passes over the shell, the spinning magnets inside the shell generate an eddy current in the aluminum, thus creating a magnetic field around the piece of aluminum. The polarity of the magnetic field of the aluminum is the same as the rotating magnets, which causes 1) the aluminum to be repelled away from the separator beyond the product flow trajectory and 2) separation of the aluminum from the rest of the product being conveyed. Products such as plastic, glass, or other process materials simply fall off the end of the separator. Here’s how it functions:

Material Feed:

Bulk material, typically a mix of non-metallic and metallic items, is evenly fed onto the ECS conveyor.

Conveyor Transport:

The vulcanized belt moves the material across the ECS system toward the separation zone.

High-Speed Magnetic Rotor:

At the end of the conveyor, a high-speed rotating magnetic rotor (made of powerful rare earth magnets) generates a rapidly changing magnetic field.

Eddy Currents Induced:

As conductive non-ferrous metals (like aluminum, copper, or brass) pass through this magnetic field, they experience an induced electric current — known as an eddy current.

Repulsion Effect:

The eddy currents create their own magnetic fields, which oppose the field of the ECS rotor. This interaction results in a strong repulsive force, propelling non-ferrous metals away from the conveyor’s path.

Separation and Collection:

Non-metallic materials (plastics, wood, glass, etc.) fall straight down due to gravity, while the repelled non-ferrous metals are thrown forward into a separate collection bin. An adjustable splitter ensures clean separation of the two streams.

Continuous Operation:

The system runs continuously, making it ideal for high-volume recycling, waste recovery, and material purification applications.

Eddy Current Separator Specification Table

US Customary Units

| MODEL # | APPROX. CAPACITY | USABLE BELT WIDTH (IN.) | APPROX. OVERALL WIDTH (IN.) | DRIVE MOTOR HP | ROTOR MOTOR HP | ROTOR PULLEY DIAMETER (IN.) |

|---|---|---|---|---|---|---|

| ECS-20 | 4 Tons/Hr. | 20 | 78 | 1.5 | 5 | 12 |

| ECS-30 | 6 Tons/Hr. | 30 | 89 | 2 | 7.5 | 12 |

| ECS-40 | 8 Tons/Hr. | 40 | 99 | 3 | 10 | 12 |

| ECX-20 | 4 Tons/Hr. | 20 | 78 | 1.5 | 5 | 16 |

| ECX-30 | 6 Tons/Hr. | 30 | 89 | 2 | 7.5 | 16 |

| ECX-40 | 8 Tons/Hr. | 40 | 99 | 3 | 10 | 16 |

Compatibility Check - Eddy Current Separator Installations

Custom Eddy Current Magnetic Separator for Commercial Plasma Manufacturing Company

Eddy Current Magnetic Separator Designed for Secondary Aluminum Recycling

Eddy Current Magnetic Separator Engineered for Water Environment Processing