High-Intensity Rare Earth Magnetic Design

MPI Magnetic Belt Feeders seamlessly integrate precision material handling with high-efficiency magnetic separation, making them an ideal solution for applications where both consistent product flow and contaminant control are critical. These systems incorporate a high-intensity magnetic separator directly beneath a durable, continuously moving belt, enabling simultaneous product feeding and automatic removal of ferrous contaminants such as stainless-steel fragments, work-hardened steel, and embedded metal. Designed for demanding environments in industries like food processing, recycling, pharmaceuticals, plastics, and general manufacturing, MPI’s Magnetic Belt Feeders ensure uniform product delivery while capturing even weakly magnetic materials that standard pulleys may miss. The high-gauss rare earth magnet circuit provides superior surface attraction, ensuring contaminants are held securely and removed efficiently, protecting downstream equipment and maintaining high product quality standards. Compact, efficient, and customizable to fit your unique processing needs, these feeders reduce labor, minimize downtime, and increase throughput—all while operating with minimal maintenance. Whether you're feeding granules, flakes, powders, or small parts, MPI Magnetic Belt Feeders deliver consistent, contaminant-free performance with every cycle.

Benefits of the Magnetic Belt Feeder From Magnetic Products, Inc

-

Dual-Function System: Material Feeding & Contaminant Removal

Combines precise, controlled product feeding with efficient magnetic separation in a single integrated unit. Ideal for bulk, granular, or powder materials, this dual-purpose design streamlines operations while ensuring product purity and equipment protection.

-

High-Capacity, Continuous Operation

Engineered to handle high-throughput environments, MPI’s Magnetic Belt Feeder is built for 24/7 processing with minimal supervision. Its robust construction and high-intensity magnetic field make it ideal for demanding industries like food processing, recycling, and manufacturing.

-

Seamless Integration Into Existing Lines

Designed for versatility, the feeder can be easily installed into new or existing production lines. It enhances material flow consistency and improves contaminant removal without requiring extensive reconfiguration of upstream or downstream systems.

-

Integrated High-Intensity Magnetic Separator

A rare earth magnetic plate mounted beneath the belt provides a high-gauss magnetic field, capable of capturing weakly magnetic and embedded ferrous contaminants that standard head pulleys may miss—improving product purity and reducing risk to downstream equipment.

-

Durable, Industrial-Grade Belt Construction

Heavy-duty conveyor belts resist wear and tear from abrasive or heavy materials, ensuring long-lasting performance even in harsh environments. The belt is designed for smooth, consistent material handling without slippage or degradation over time.

-

Precise, Adjustable Material Flow

Equipped with adjustable belt speeds and feed rate controls, the feeder allows operators to fine-tune the material flow to match the needs of specific applications. This level of control optimizes throughput and ensures reliable performance across a range of materials and conditions.

-

Customizable Configurations

Available in a variety of sizes, magnetic strengths, belt materials, and control options to suit specific product types, flow rates, and space constraints. MPI works closely with customers to tailor each unit to their unique processing needs.

-

Energy-Efficient Operation

The system is designed to deliver maximum separation performance with minimal energy consumption. The permanent magnet requires no power supply, contributing to lower operating costs and a more sustainable facility footprint.

-

Sanitary, Food-Grade Options Available

For hygienic processing environments such as food or pharmaceutical applications, FDA-compliant materials and clean-in-place (CIP) compatible designs are available. These options meet strict safety and sanitation standards while maintaining magnetic performance.

Magnetic Belt Feeder Product Details

MPI’s Magnetic Belt Feeder is a dual-function system that combines precise product feeding with high-efficiency magnetic separation. The unit features a durable conveyor belt that runs over a powerful, high-intensity rare-earth magnetic plate. This design enables the feeder to consistently regulate the flow of material while simultaneously removing ferrous contaminants, including weakly magnetic metals such as stainless steel, work-hardened steel, and embedded particles.

Here’s how it works step by step:

Material Introduction

Bulk material is evenly fed onto the moving conveyor belt, either manually or via upstream process equipment. The feeder is designed to maintain a controlled, uniform product flow.

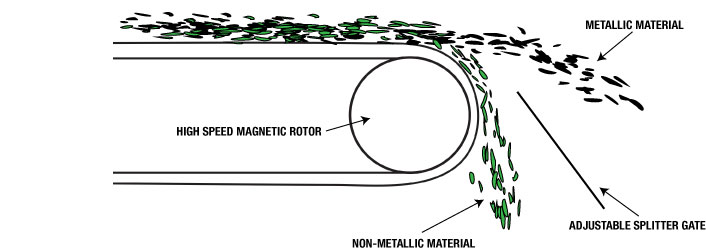

Magnetic Separation Zone

As the material travels along the belt, it passes directly over a high-gauss rare earth magnetic plate. This plate is located beneath the belt and spans a critical section of its length, creating an intense magnetic field at the surface.

Ferrous Contaminant Capture

The magnetic field penetrates through the belt to attract and hold ferrous particles present in the product stream. This includes fine or weakly magnetic metals that may be embedded within the product or difficult to detect with standard magnetic equipment.

Material Discharge

Non-magnetic, clean product continues along the conveyor path and is discharged from the end of the belt. Since the magnetic field does not affect these materials, they remain unaffected and exit freely.

Contaminant Removal

Captured ferrous contaminants are held tightly against the belt until they move out of the magnetic field zone. At that point—typically near the return side of the belt or through a designated discharge path—the magnetic grip is released, and the metal falls into a separate collection chute or bin.

Continuous, Automatic Operation

The entire process runs automatically and continuously, requiring no operator intervention. The design eliminates the need for manual sorting or stopping the production line, thereby reducing downtime and labor requirements.

Optional Enhancements

Optional features such as variable speed drives, custom belt widths, and integrated controls can be added to meet specific application needs and enhance separation efficiency.

By integrating feeding and separation into a single, compact, and self-contained system, MPI’s Magnetic Belt Feeder delivers unmatched efficiency, consistency, and protection for downstream equipment, making it an invaluable asset in any process that demands both precision and purity.

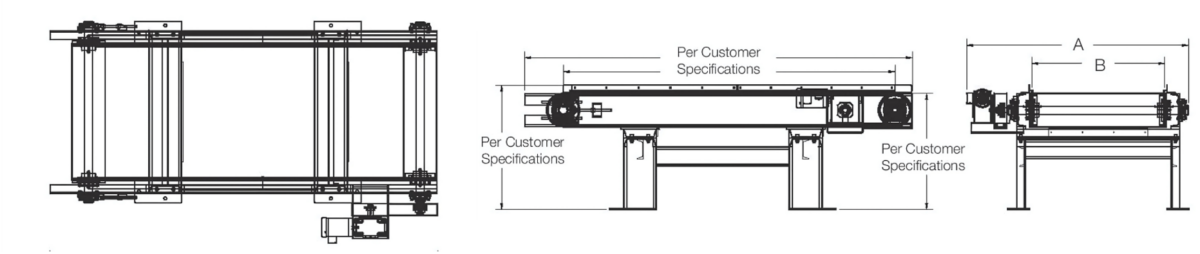

Magnetic Belt Feeder Specification Table

US Customary Units

| MODEL # | (A) UNIT WIDTH (IN.) | (B) BELT WIDTH (IN.) | ROLLER DIAMETER (IN.) |

|---|---|---|---|

| MBF-1220 | 52.20 | 20 | 12 |

| MBF-1230 | 62.20 | 30 | 12 |

| MBF-1248 | 80.20 | 48 | 12 |

Magnetic Belt Feeder Installations & Variations

Magnetic Belt Feeder Designed for Mining & Mineral Processing

Magnetic Belt Feeder Designed for Metalworking & Manufacturing

Magnetic Belt Feeder for Bulk Grain Processing