Metal Control Solutions for the Water Treatment, Liquid Chemical, and Additives Industries

Metal contamination can have serious consequences in water treatment, liquid chemical production, and additive blending—whether for municipal utilities, industrial wastewater, agricultural chemicals, or specialty formulations. Even microscopic ferrous particles can:

- Catalyze chemical reactions

- Damage pumps, valves, or filtration media

- Compromise product purity and consistency

- Clog dosing equipment or spray nozzles

MPI’s magnetic solutions are engineered to function within closed-loop, pressurized, or corrosive liquid systems, removing metallic contaminants during:

- Raw material receiving and blending

- Inline pumping and transfer

- Mixing, dosing, and filtration

- Final product packaging

Many MPI systems are available in sanitary, food-grade, and chemical-resistant configurations to meet stringent hygiene and process compatibility requirements.

MPI magnetic separation and detection solutions help chemical, water, and additive processors:

- Maintain formulation integrity and chemical balance

- Reduce equipment wear and filter fouling

- Ensure uninterrupted flow and dosing precision

- Meet hygiene, safety, and environmental regulations

- Optimize product purity and minimize rework or rejection

MPI keeps liquid processes clean, consistent, and compliant from municipal water treatment to polymer additives.

Turnkey Solutions for Water Treatment, Liquid Chemical, and Additives From Magnetic Products, Inc

-

Prevents Premature Equipment Wear and Downtime

Captures fine metal particles before they reach pumps, valves, meters, and sensors, reducing maintenance costs and unplanned line stoppages.

-

Preserves Chemical Integrity and Product Quality

Avoids reaction-altering contamination in sensitive formulations such as polymers, flocculants, or pH modifiers.

-

Protects Filtration and Membrane Systems

By removing particles upstream, MPI systems extend the life of ultrafiltration, nanofiltration, and reverse osmosis units.

-

Supports Compliance with EPA, FDA, and Industry Standards

Helps meet strict environmental, safety, and product purity requirements across municipal, food-grade, and chemical sectors.

-

Engineered for Corrosive and High-Flow Applications

Constructed from 304/316 stainless steel with high-pressure fittings and specialized coatings for acid, alkali, or brine environments.

-

Customizable for Sanitary and CIP (Clean-In-Place) Operations

Options are available for polished surfaces, sanitary tri-clamp fittings, and tool-less access to food, beverage, and pharmaceutical-grade systems.

-

Low Pressure Drop and Minimal Flow Disruption

Designed to operate inline without impacting flow rate or system pressure, critical in dosing and continuous treatment systems.

-

Fast and Easy Maintenance with Quick-Clean Designs

Drawer and cartridge designs allow rapid cleaning with minimal system disruption, perfect for multi-batch or continuous operations.

How Does the Water Treatment, Liquid Chemical, and Additives Industry Use Magnets?

US Customary Units

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

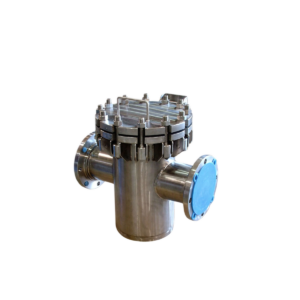

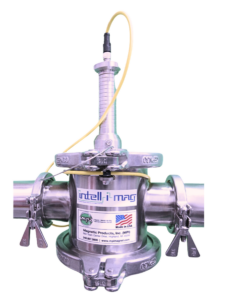

| Liquid Trap Magnets | Inline liquid transfer or dosing lines | Powerful magnetic cartridges capture ferrous particles from flowing liquids, sanitary and jacketed versions available for hot or viscous materials | Liquid transport and circulation | Captures iron and fine steel during pumping or continuous loops |

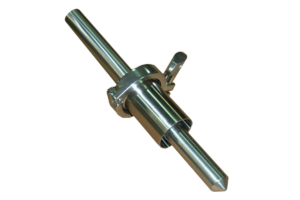

| Inline Pneumatic Drawer Magnets | At powder/liquid mixing stations | Prevent metal contamination from dry additive injection before it enters the liquid stream | Blending and dosing | Removes contaminants from additive feeds entering mixers or tanks |

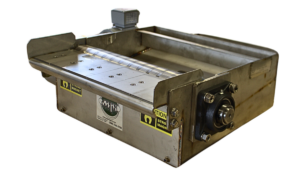

| Plate Magnets | Hopper feed or bag dump stations | Captures tramp metal from powders and granulates prior to blending | Raw ingredient receiving | Eliminate tramp iron from dry powders or chemicals before mixing |

| Drawer Magnets | Powder silo or dry raw material intake | Protects mixers and dispersers from abrasive metal fines | Raw ingredient receiving | Eliminate tramp iron from dry powders or chemicals before mixing |

| Drum Separators | Clean metal debris from sludges, semi-liquids, or rework flows | Reclaimed/recycled chemical streams | For operations using semi-solids or thick slurries, remove metal during line transfer | |

| Magnetic Conveyors or Transfer Chutes | Specialty wet or slurry handling | For operations using semi-solids or thick slurries; remove metal during vertical transfer | Reclaimed/recycled chemical streams | Clean metal debris from sludges, semi-liquids, or rework flows |

| Metal Detectors | Final QC before filling or shipment | Detects stainless steel, brass, and non-ferrous metals that magnets might miss | Final product QA | Detect any remaining metals before product enters bulk tanks or drums |