Direct Replacement of Vacuum Cups

MPI’s Permanent Magnet Parts Lifter is a compact, handheld magnetic tool engineered to make lifting, positioning, and handling small to medium ferrous parts safer and more efficient in metalworking and assembly environments. Using a powerful permanent magnet core, it provides instant, secure hold on steel sheets, blanks, or scrap pieces without the need for hooks, clamps, or direct hand contact. Operators simply engage or disengage the magnetic force with an easy-to-use lever, minimizing finger strain and improving ergonomics. Lightweight yet rugged, this tool increases productivity and reduces injury risks in repetitive part handling tasks common to machine shops, pressrooms, welding cells, and fabrication stations.

Benefits of the Permanent Magnet Parts Lifter (PMPL) From Magnetic Products, Inc

-

No External Power Needed

Always ready for use — no batteries or cords required.

-

Instant One-Handed Activation

A simple lever allows quick engagement and release for fast cycle work.

-

Improves Operator Safety

Minimizes direct contact with sharp or oily parts, reducing cuts and slips.

-

Compact & Portable

Lightweight design fits easily in the toolbox or on a workbench.

-

Strong Holding Power

Rare-earth or ceramic magnet provides a reliable grip on ferrous materials.

-

Reduces Finger Strain & Fatigue

Eliminates repetitive pinching and gripping of small metal parts.

-

Rugged & Maintenance-Free

Built to withstand daily shop use with no moving parts to service.

-

Versatile Applications

Ideal for press loading, scrap removal, sorting, or positioning small steel components.

Permanent Magnet Parts Lifter (PMPL) Product Details

How MPI's Permanent Magnet Parts Lifter

Position

Align the Permanent Magnet Parts Lifter directly over the ferrous part you wish to pick up.

Engage

Flip or slide the manual lever to the ON position. This moves the internal magnet into the active state, extending its field outward.

Lift

The magnet securely grips the part, allowing the operator to lift, carry, or reposition it easily with one hand.

Position & Place

Move the part to its desired location—such as into a press, onto a machine bed, or into a bin.

Release

Flip the lever back to the OFF position. This retracts the magnetic field internally, releasing the part cleanly with zero residual hold.

Ready for Next Use

Repeat the cycle—no power, charging, or downtime required.

Permanent Magnet Parts Lifter (PMPL) Specification Table

US Customary Units

| PMPL MODEL # | (A) HEIGHT (IN.) | DIAMETER (IN.) | 26 MATERIAL GAUGE HOLDING VALUE (LBS.) | 18 MATERIAL GAUGE HOLDING VALUE (LBS.) | 12 MATERIAL GAUGE HOLDING VALUE (LBS.) | 7 MATERIAL GAUGE HOLDING VALUE (LBS.) |

|---|---|---|---|---|---|---|

| PMPL-175-250-REN-S | 2.50″ | 1.75″ | 5 | 5.25 | 6 | 6.5 |

| PMPL-300-350-REN-S | 3.50″ | 3.00″ | 20.5 | 30.5 | 34 | 36 |

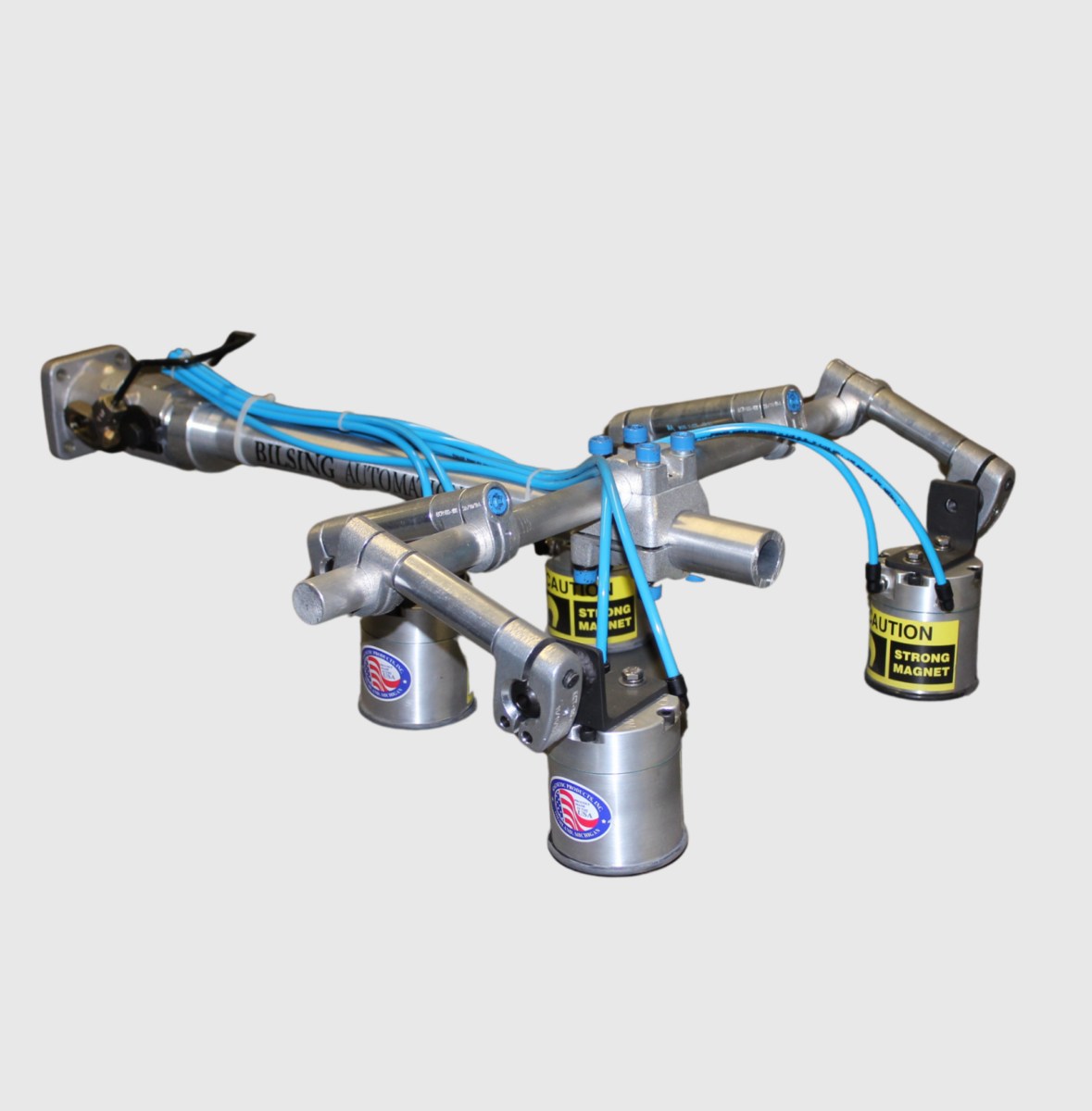

Permanent Magnet Parts Lifter (PMPL) Installations & Variations

Custom Permanent Magnet Parts Lifter to Replace Vacuum Cups

Custom Permanent Magnet Parts Lifter with Robust Design and Quiet Operation

Custom Permanent Magnet Parts Lifter in Various Size Options