Easy Installation Into New or Existing Belted Conveyors

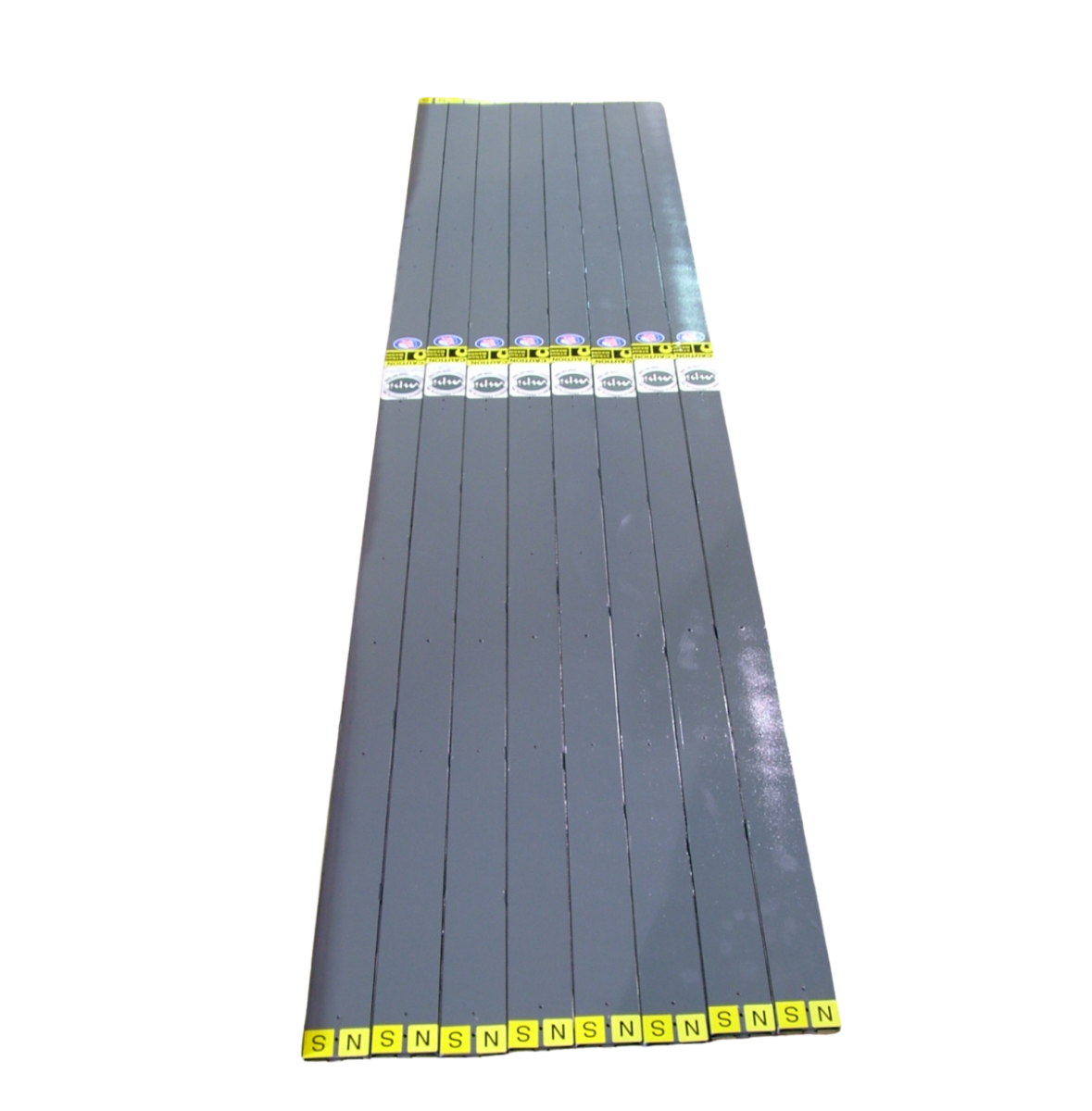

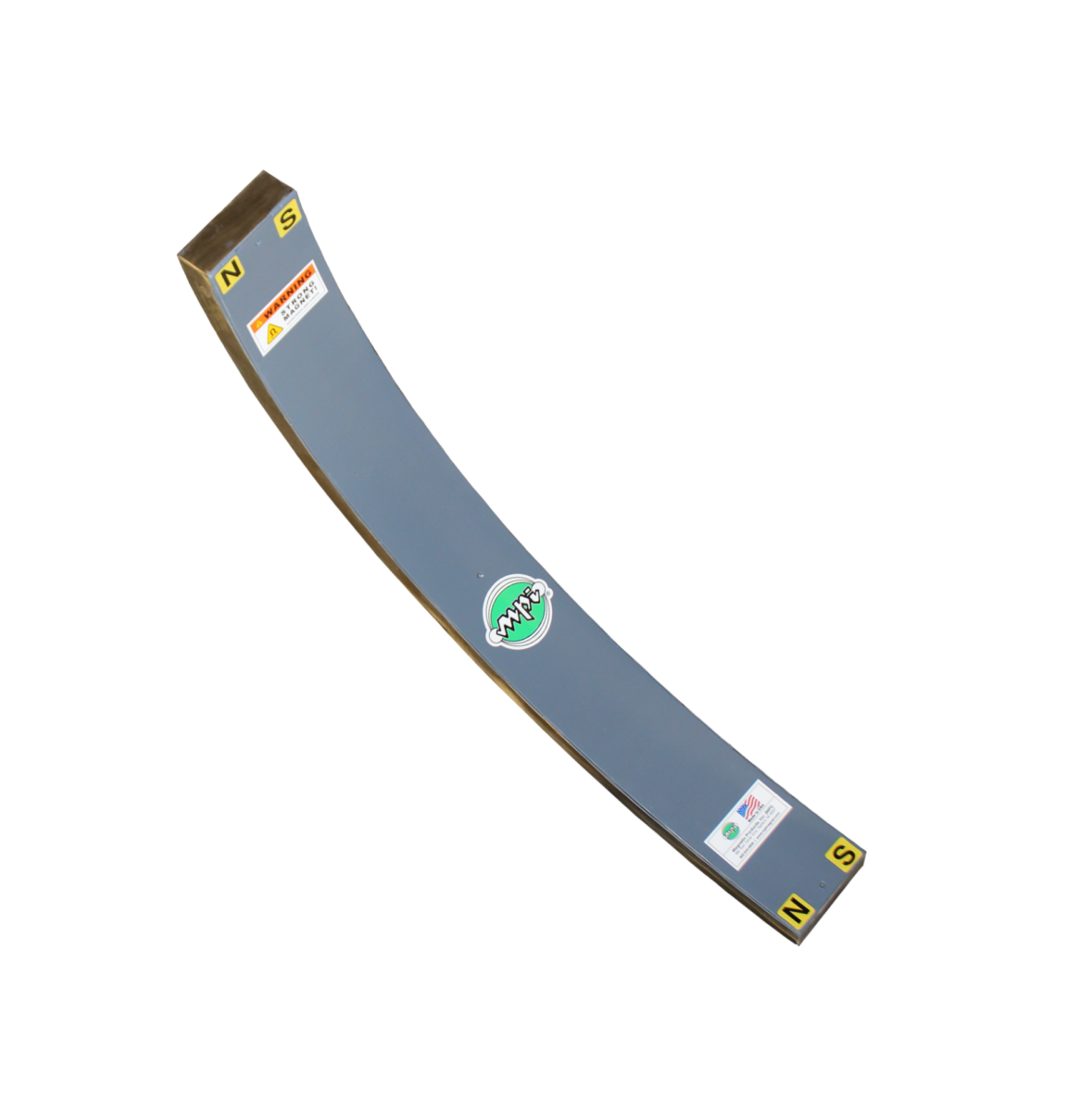

MPI’s Magnetic Rails are engineered to securely hold, position, and guide ferrous parts as they move along conveyor lines — without physical guides or clamps. Installed beneath a slider-bed belt or conveyor track, these rails generate strong, uniform magnetic force that grips cans, lids, sheets, or light stampings firmly against the belt, preventing slippage or misalignment. Ideal for high-speed can handling, lid placement, part transfer, and scrap discharge, MPI Magnetic Rails improve flow control, reduce jams, and ensure smooth operation on straight runs or inclines. Rugged, low-maintenance, and easy to adjust, they deliver consistent performance in demanding packaging and metalworking environments.

Benefits of the Magnetic Rails From Magnetic Products, Inc

-

Uniform Non-Contact Holding

Keeps ferrous parts steady without rails or mechanical guides.

-

Supports Steep Inclines

Moves metal parts uphill, downhill, or vertically without slipping.

-

High-Speed Stability

Maintains precise alignment for lightweight cans or lids at fast line speeds.

-

Compact & Flexible Design

Available in various lengths and shapes to match any conveyor layout.

-

Adjustable Strength Options

Some models allow tuning the magnetic hold for different part weights.

-

Durable, Sealed Construction

Resists moisture, debris, and corrosion.

-

Quick Retrofits

Easily integrated into new or existing conveyor beds.

-

Low Operational Cost

No moving magnet parts; minimal wear, low maintenance.

Magnetic Rails Product Details

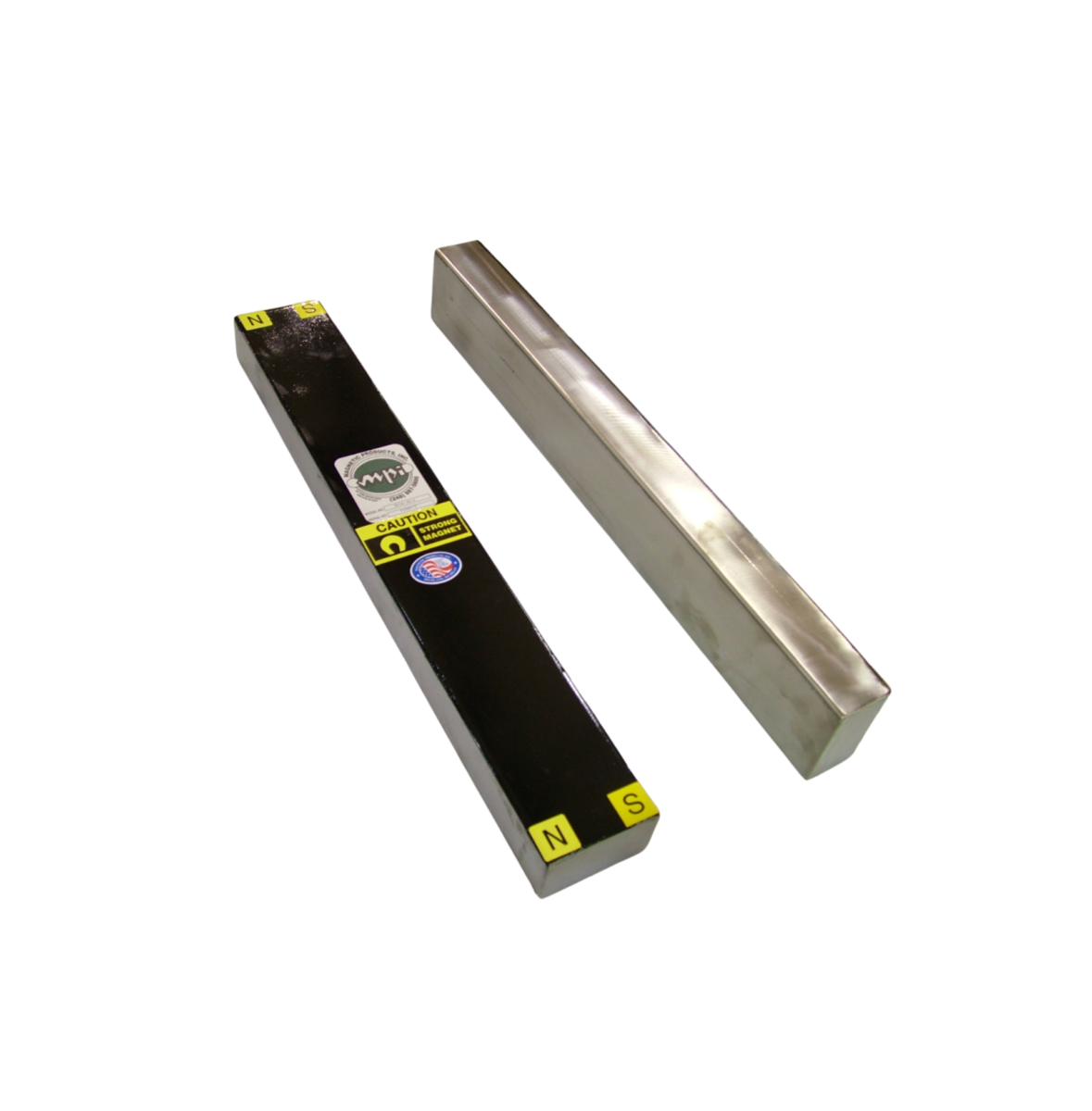

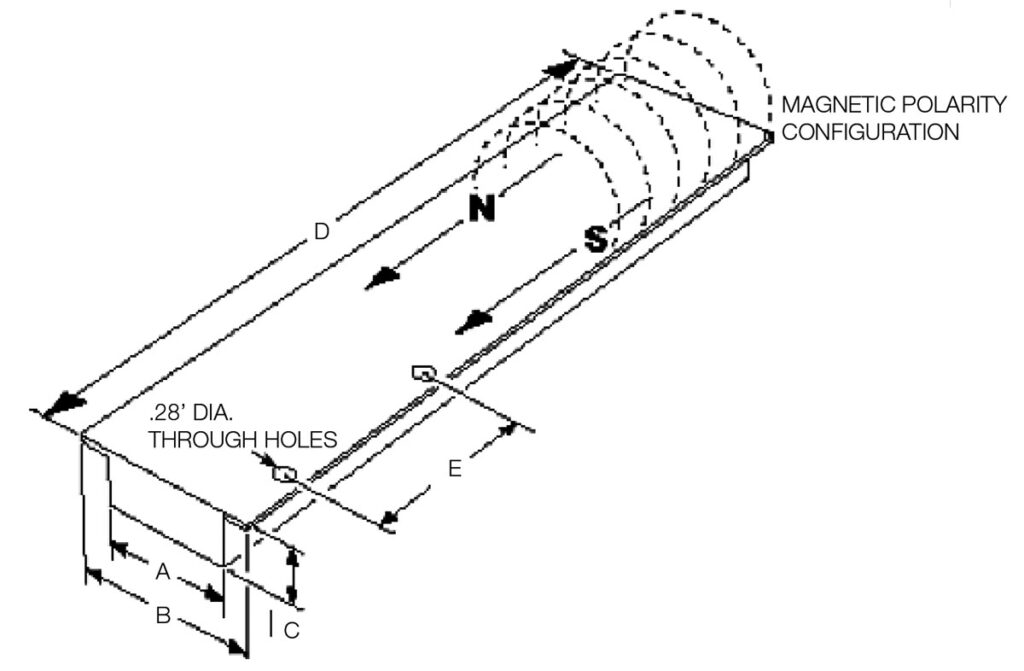

Magnetic Box Rails and T-type box Rails are usually mounted in tandem with magnetic pulleys and other rails beneath a conveyor’s belt. The standard design provides quick installation to a conveyor’s framework or table, but it can also be custom-designed and manufactured to fit your specifications.

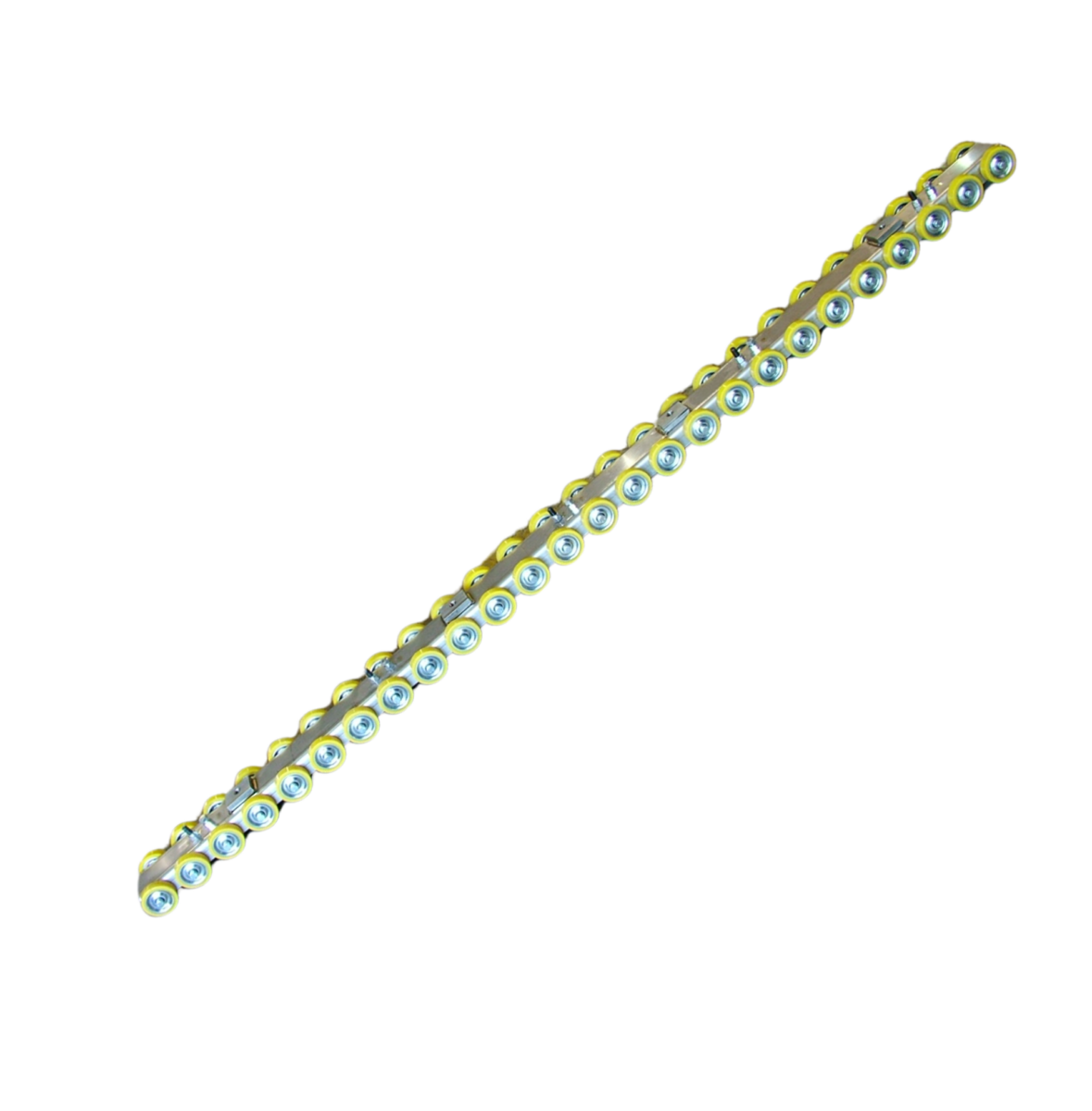

Pulleys are typically used as transfer devices in belt conveyors. As metal nears the pulley’s magnetic field, it is attracted and held to the conveyor’s belt until it reaches the transfer point.

- Install: Mount rails beneath the conveyor belt’s carrying surface or embed inside a slider-bed track.

- Activate: Internal permanent magnets create a consistent field through the belt.

- Load: Ferrous parts travel over the rail zone; the magnetic field pulls them against the belt.

- Guide: The magnetic force holds each part in place, preventing bounce, roll, or slide.

- Move: Parts ride smoothly along straight sections, curves, or inclines without misfeeds.

- Release: Once past the rail, the magnetic field naturally ends, releasing parts for next-stage processing.

Magnetic Rails Specification Table

US Customary Units. WIDTH (B): Built to customer’s specifications (1″ flange, standard). LENGTH (D): Built to customer specifications (up to 8″). TAP DISTANCE (E): Built to customer specifications (12″ on-center in backplate standard).

| RAIL AND PULLEY MODEL # | (A) INNER WIDTH (IN.) | (C) THICKNESS (IN.) |

|---|---|---|

| BR-2 | 2.63″ | 0.56″ |

| BR-4 | 4.19″ | 0.81″ |

| BR-6 | 4.19" | 1.06" |

| BR-8 | 4.19" | 1.31" |

| BR-12 | 4.19" | 1.94" |

| BR-16 | 5.19" | 2.56" |

| BR-24 | 8.19" | 4.06" |

| BRT-2 | 2.63" | 0.56" |

| BRT-4 | 4.19" | 0.81" |

| BRT-6 | 4.19" | 1.06" |

| BRT-8 | 4.19" | 1.31" |

| BRT-12 | 4.19" | 1.94" |

| BRT-16 | 5.19" | 2.56" |

| BRT-24 | 8.19" | 4.06" |

Magnetic Rails Installations & Variations

MPI Magnetic Rail and Pulley System Designed for Canning Operation

Custom Magnetic Rail with Rugged Track Cover with Specialty Coating

Wide Magnetic Rail with Food Grade Welds and Finishing