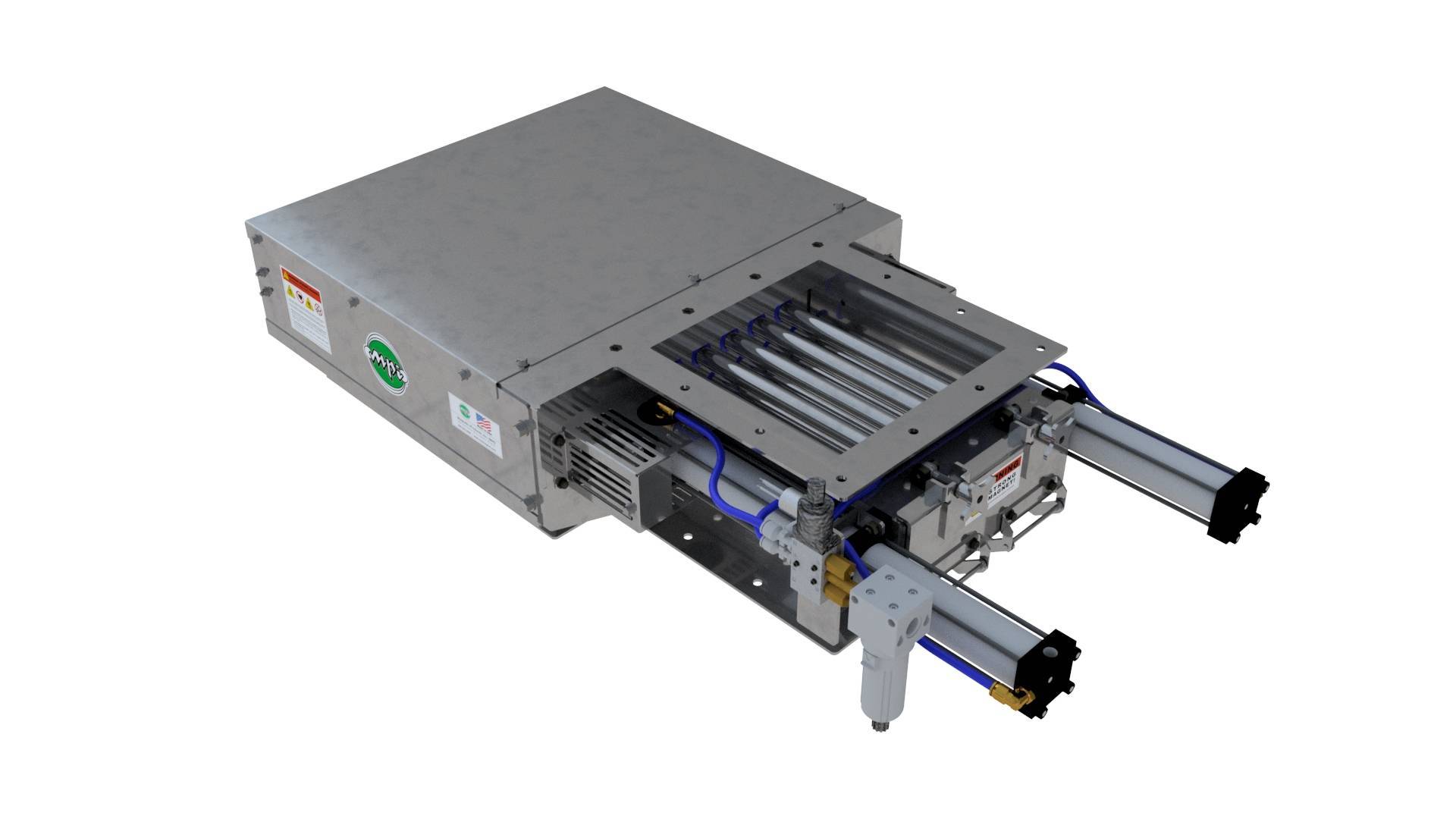

Automated Self-Clean Drawer Magnet

Protect Processing Equipment

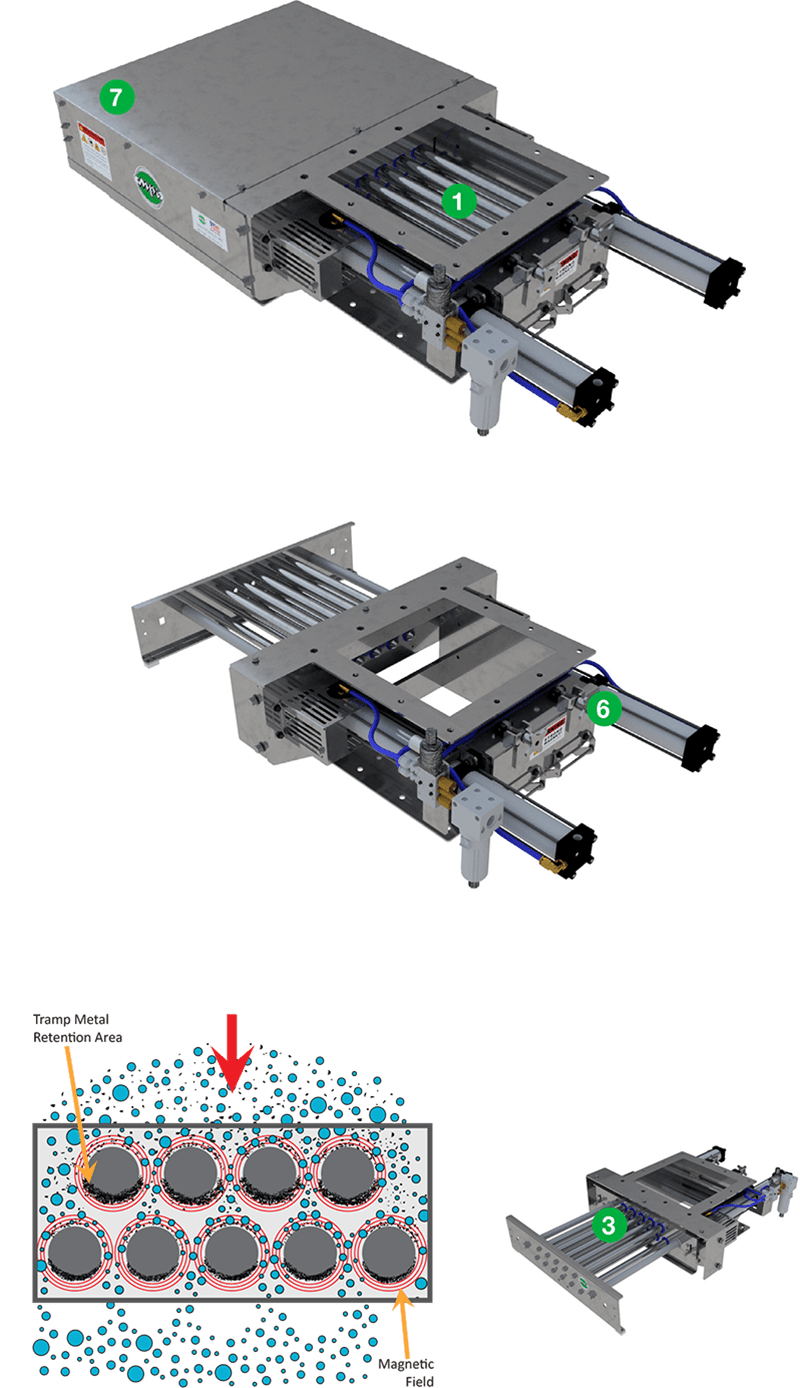

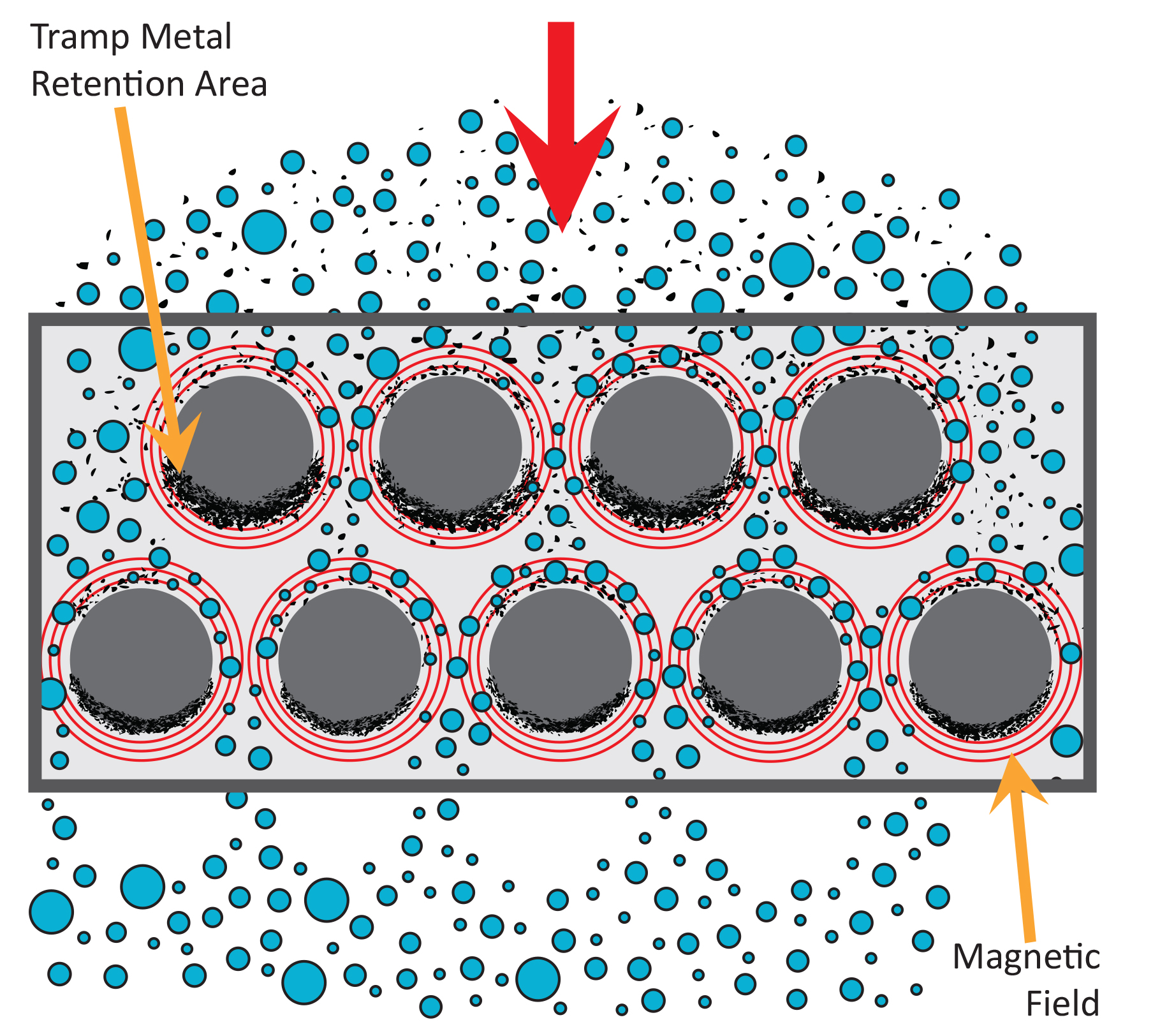

MPI’s Automated Self-Clean 200 Series Drawer Magnets utilize a “Type A” magnetic circuit, which is ideally suited to capture small contaminants, such as wire, metal shavings and metal wear from dry powder or granular free-flowing product streams in gravity-fed vertical chutes. This Drawer Magnet protects processing equipment, such as milling extruding and mixing, while assuring high product quality standards with automatic magnet cleaning for maximum magnet performance.

Benefits of the Automated Self-Clean Drawer Magnet From Magnetic Products, Inc

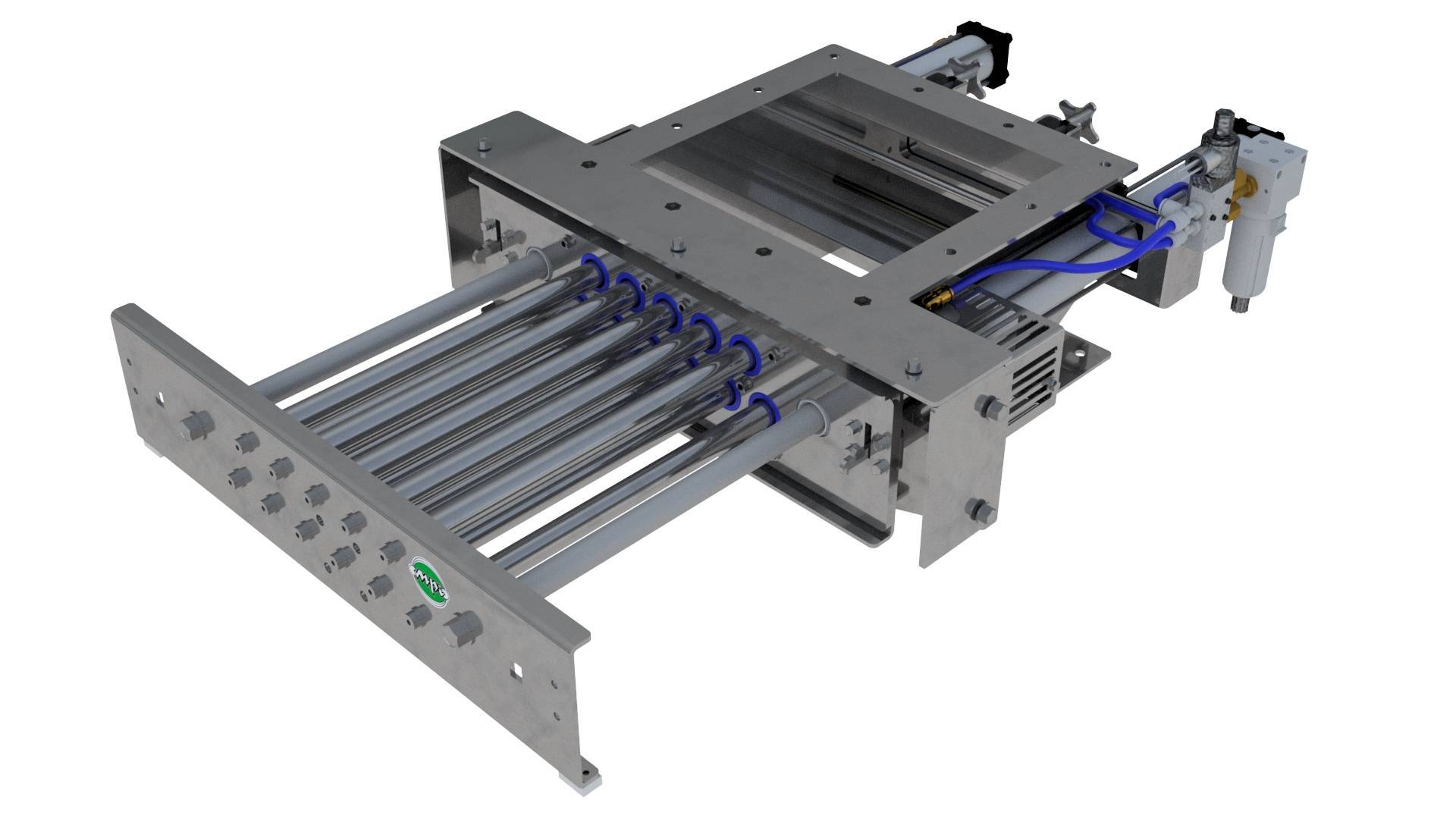

- Magnetic Tubes:

- MPI drawer magnets feature two tiers of high intensity rare earth magnetic tubes that ensure the highest levels of magnetic filtration through direct product contact on the tubes, removing ferrous tramp metal from the product stream.

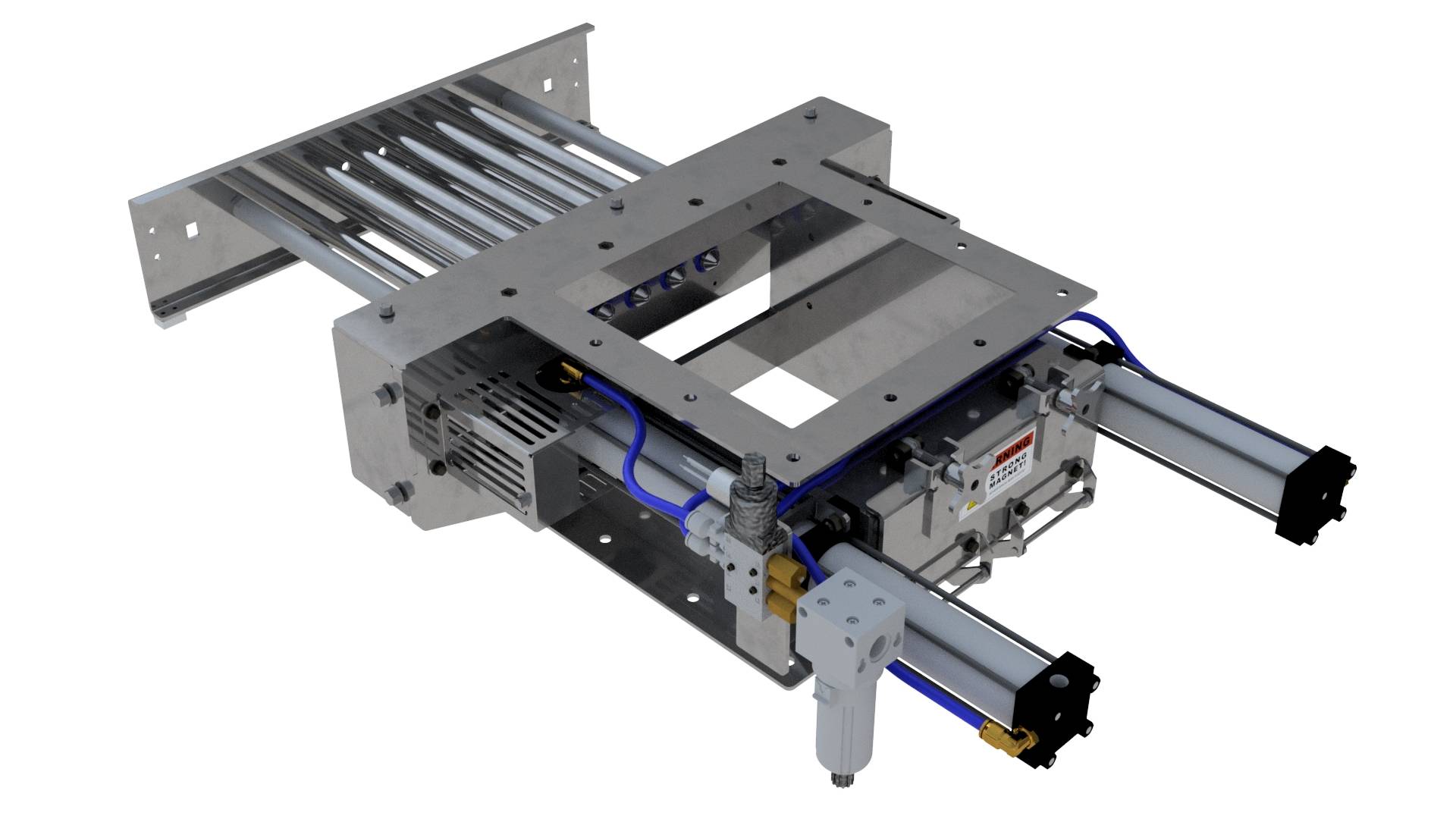

- Cleaning Cycle:

- Start: After manually or electrically actuating the solenoid, the cylinders retract, pulling the magnetic tubes through the stripper assembly to deposit the collected tramp iron outside of the product flow area.

- Finish: The cylinders return to the run position, pushing the magnetic tubes back through the stripper assembly into the housing (working position)

- Floating Stripper Seal:

- Adjusts to tube resulting in even wear and longer life between replacements.

- Held in place by machined and fastened laminated stripper plate assembly.

- Stripper Latch:

- Releases stripper plate assembly once the plate has been clearly pulled away from the sealing plate.

- Prevents accidental cleaning of the tubes in the product flow area, commonly caused when the stripper assembly is stuck to the sealing plate.

- Sani-TIGHT Seal™ Gasket:

- Type: Compression style “O-ring” cord gasket.

- Sealing plate: ½” thick machined stainless plate.

- 100% Positive seal, cannot be over-compressed.

- Sanitary: Gasket can be removed and replaced for wash-down, no adhesive required.

- Rear Access Panel:

- For easy inspection and maintenance.

- Bolt-On Stainless Steel Safety Cage:

- Removeable cover for magnet maintenance and testing.

- Multiple options for tramp metal recovery.

- Grounding Strap:

- Provides a discharge path for static buildup.

- Continuous Automated Self-Cleaning Model:

- For high level tramp metal or weakly magnetic tramp metal applications, this system continuously cleans on the go without stopping production.

Automated Self-Clean Drawer Magnet Product Details

How It Works

Self-Clean Drawer Magnet

Self-Clean Drawer Magnet

The product stream flows through a series of 1” diameter magnetic tubes designed to create an extremely effective magnetic circuit. Each row of magnetic tubes is staggered to prevent bridging or choking of the product stream and to maximize magnetic filtration as product flows through the housing. Tramp metal contaminants are attracted to the magnetic tubes. The pneumatically operated cleaning system safely removes tramp metal from the product stream to a disposal area outside the product flow area.

Product Options

- Cleaning Method:

- Manual clean

- Manual quick-clean

- Automated self-cleaning (standard)

- Continuous automated self-cleaning

- Number of Tiers of Tubes:

- 100 Series with 1 tier of tubes

- 200 Series with 2 tiers of tubes (standard)

- 300 Series with 3 tiers of tubes

- 400 Series with 4 tiers of tubes

- Material Construction:

-

- 304 Stainless Steel (standard)

- 316 Stainless Steel

-

- Magnetic Tubes [reference datasheet MT]:

- Ceramic

- REN Rare Earth (standard)

- Hi-G high-performance Rare Earth

- TW Thin Wall high-performance Rare Earth

- Magnetic Material Temperature:

- 400°F (204°C) @ 3.5 MGO (ceramic)

- 176°F (80°C) @ 52+ MGOe (rare earth) (standard)

- 248°F (120°C) @ 48 MGO (rare earth)

- 356°F (180°C) @ 38 MGO (rare earth)

- 662°F (350°C) @ 30 MGO (rare earth)

- Tube Spacing:

- 2” horizontal and vertical spacing (standard)

- 3” (approx.) horizontal and vertical for increased flowability (recommended for products that bridge or choke) (adds 1” to OAH)

- 3” (approx.) horizontal only for increased flowability (available for height restrictions only)

- Custom configurations available

- Tube Coatings:

- Stainless steel with no coating (standard)

- Synergistic Coating

- Gasket Material:

- White silicone, FDA approved (standard)

- Buna, FDA approved

- Metal detectable blue silicone, FDA approved

- Stripper Material:

- UHMW material (standard) Maximum temperature: 180°F (82°C)

- Hydex material Higher wear resistance compared to UHMW

- Higher maximum temperature: 221°F (105°C)

- Metal Detectable Hydex

- Teflon material Higher wear resistance compared to UHMW

- Higher maximum temperature: 500°F (260°C)

- Transitions: Stainless steel transitions for easy installation

- Not included (standard)

- Inlet, outlet or both, configured as required for installation

- Companion Flanges: Matching companion flanges for a customer to weld onto existing chute work for easy installation

- Not included (standard)

- Stainless steel companion flanges

- Carbon steel companion flanges

- Housing Vibrator: Housing mounted vibrators improve product flowability over magnetic tubes

- Mounting holes only (standard)

- Pneumatic vibrator

- Reed Switches: For position verification of cylinders in open and closed position

- Not included (standard)

- Quantity 1 bolt-on magnetic reed switch for unit closed confirmation (120VAC/VDC 500MA)

- Quantity 2 bolt-on magnetic reed switches for unit open and closed confirmation (120VAC/VDC 500MA)

- Valve Package:

- 120VAC explosion-proof rated (standard)

- 240VAC explosion-proof rated

- 12VDC explosion-proof rated

- 24VDC explosion-proof rated

- A manual lever to actuate magnet cycle

- Safety Cage Design:

- Safety cage with removable cover for magnet access (standard)

- Safety cage with hinged cover for easy magnet access

- Safety cage with hinged cover, Lexan viewing window, and DESTACO latches for easy magnet access and visual drawer position monitoring

- Tramp Metal Collection Method:

- Open bottom safety cage with MPI standard flange (standard)

- Removable collection tray (split tray for sizes 16” and larger)

- Bolt-on tramp iron collection transition to 4” pipe with sock bead to attach collection pipe or bag

- Rack and Pinion System: Large drawers, adhesive and abrasive products can benefit from the added alignment provided by the rack and pinion system. The RP system provides smooth and jam-free cleaning of the magnetic tubes ensuring that all magnet tubes travel the exact same distance, at the same time, from left to right, top to bottom, resulting in reduced system wear and improved magnetic tube cleaning.

- Not included (standard)

- Included

- Internal Drawer Support: Provides drawer support when cycling and mechanically fastens tubes together

- Not included (standard on sizes 16” and smaller)

- Included (standard on all sizes 18” and larger)

- Visual Position Indicators: Mechanical color-coded flags move with drawer and indicate drawer position

- Not included (standard)

- Included

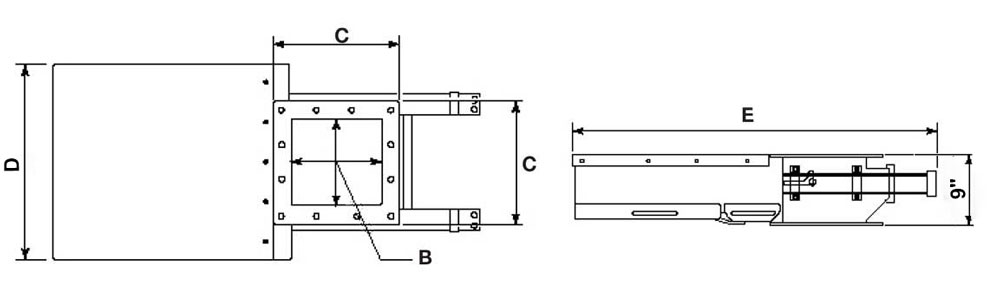

Specifications

US Customary Units

| DRAWER MAGNET MODEL # | DMU Opening (B) | Flange Width (C) |

Overall Width (D) |

Overall Length (E) | Magnet Tubes | Unit Approx. Weight | Flow Rate |

| IN | IN | IN | IN | 2 Rows | LBS | FT3/HR | |

| DMU-208-SC | 8² | 12.25 | 22.75 | 43 | 7 | 170 | 600 |

| DMU-210-SC |

10² | 14.25 | 24.75 | 45 | 9 | 180 | 1,350 |

| DMU-212-SC | 12² | 16.25 | 26.75 | 47 | 11 | 190 | 2,400 |

| DMU-214-SC |

14² | 1825 | 28.75 | 49 | 13 | 200 | 3,037 |

| DMU-216-SC | 16² | 20.25 | 30.75 | 51 | 15 | 230 | 3,750 |

| DMU-218-SC |

18² | 22.25 | 32.75 | 53 | 17 | 270 | 5,400 |

| DMU-220-SC | 20² | 24.25 | 34.75 | 55 | 19 | 300 | 6,337 |

Metric Units

| DRAWER MAGNET MODEL # | DMU Opening (B) | Flange Width (C) |

Overall Width (D) |

Overall Length (E) | Magnet Tubes | Unit Approx. Weight | Flow Rate |

| CM | CM | CM | CM | 2 Rows | KG | M3/HR | |

| DMU-208-SC | 20² | 31 | 58 | 109 | 7 | 77 | 16.99 |

| DMU-210-SC |

25² | 36 | 63 | 115 | 9 | 82 | 38.23 |

| DMU-212-SC | 30.5² | 41 | 68 | 120 | 11 | 86 | 67.96 |

| DMU-214-SC |

35.5² | 46 | 73 | 125 | 13 | 91 | 86.00 |

| DMU-216-SC | 41² | 51 | 78 | 130 | 15 | 104 | 106.18 |

| DMU-218-SC |

46² | 56 | 83 | 133 | 17 | 122 | 152.91 |

| DMU-220-SC | 51² | 61 | 88 | 140 | 19 | 136 | 179.44 |

Other sizes are available upon request.