Eco-Flow Magnetic Filter

Plug and Play Filtration

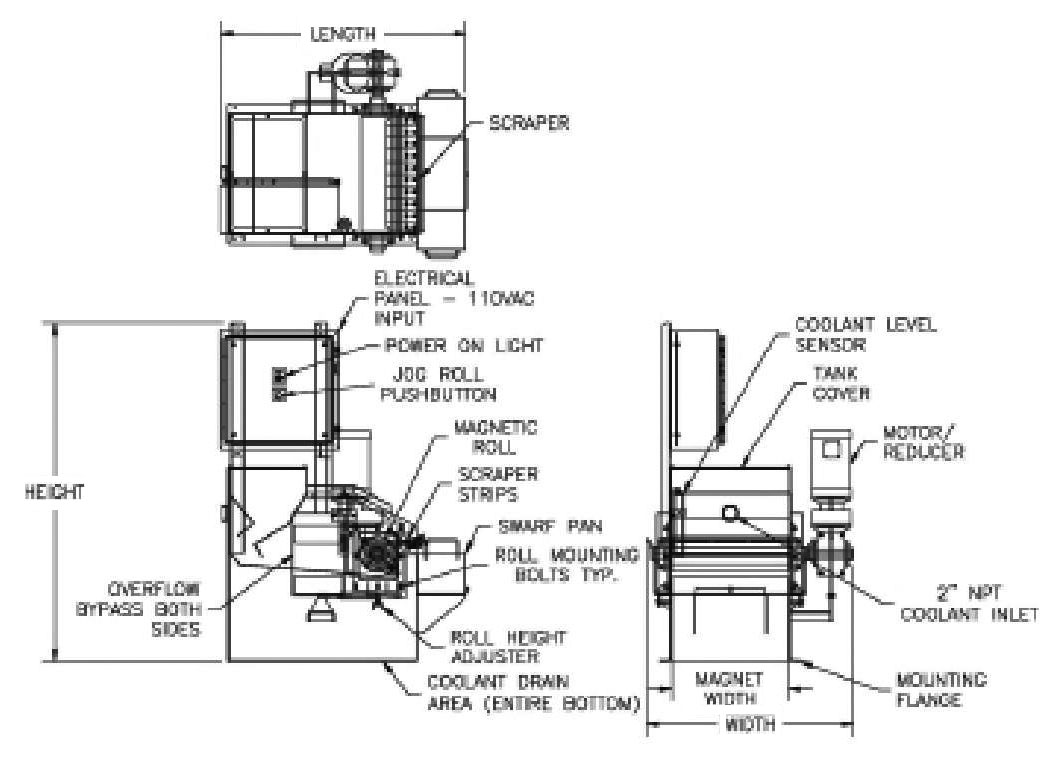

Eco-Flow provides true plug and play filtration. The fluid intake system keeps coolants calm, allowing contaminants to contact the roll at a low velocity for improved magnetic filtration. MPI’s integrated, indexing magnetic roll never needs replacement. Eco-Flow’s adjustable blades allow for maximum magnet cleaning and coolant recapture, eliminating the need for plastic squeegees. Eco-Flow also features an automatic coolant level sensor that monitors the level of incoming fluid to maximize filtration and avoid coolant overflow. There is also a bypass that eliminates potential spills in case of electrical or mechanical failure. Surrounding areas stay clean and potential accidents are prevented with Eco-Flow.

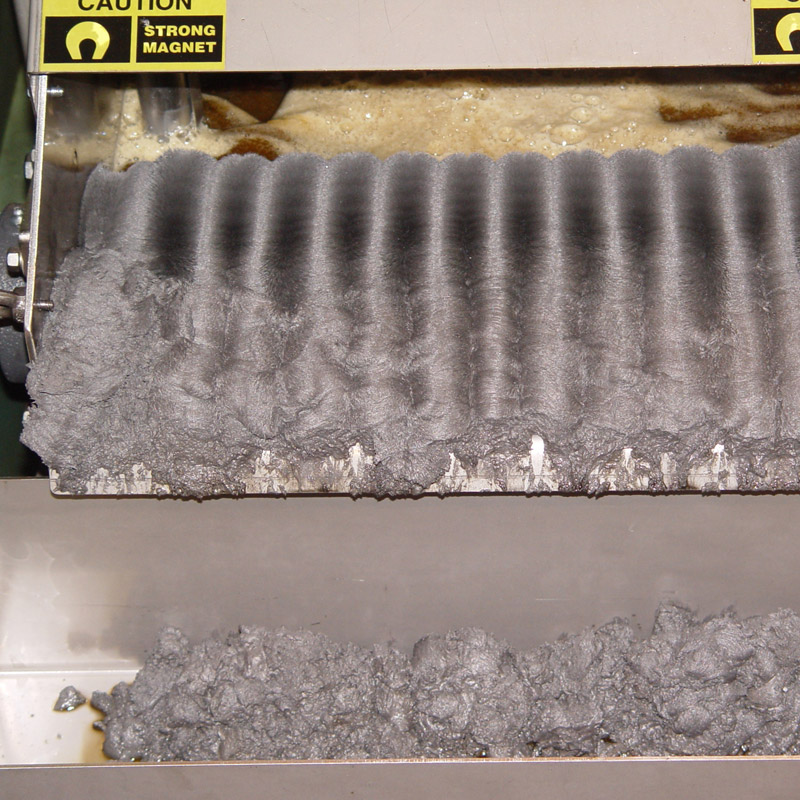

The Eco-Flow is a continuous cleaning magnetic separator that removes grinding swarf and other contaminants from coolants and deposits them directly into a disposal bin, eliminating the costs associated with collecting, transporting, and dumping waste materials. As swarf is removed, fluids are fed automatically back into the reservoir tank. An extremely dry swarf “cake” is produced. A drier cake means fewer messy, oily pools around machinery, and improved coolant recovery, reducing consumable costs. Magnetic technology is green, and substantially reduces both the need to buy costly consumables and the associated downtime required to change paper filters.

Benefits of the Eco-Flow Magnetic Filter From Magnetic Products, Inc

- System ships complete with magnetic roll, scraper system, fluid tank, inlet port (sized to specifications), and controls

- Plugs into a standard 110V outlet

- High intensity rare earth magnetic material traps contaminants

- Stainless steel construction

- Automatic and continuous self-cleaning

- Custom sizes and configurations available

Eco-Flow Magnetic Filter Product Details

How It Works

The MPI M-10000 horizontal motion conveyor uses modular sections of pans assembled together to form a continuous single pan. It is driven by a single section that has a drive and is connected to the pan above. This drive creates a slow, low frequency movement with a quick return that drives material forward. Utilizing a single continuously formed pan assembly ensures the scrap metal is contained while also eliminating jams caused by pinch points.

The shaker pans are supported by maintenance-free Rubber Suspension Technology (RST) bearings. Unlike traditional bearings, RST bearings use pressed rubber around a square shaft, which requires no grease. This gives the bearing several functions in one, including a torsion spring, pivot bearing, and anti-vibration mount. The design also eliminates metal on metal contact points, which are friction locations that are known to create wear or maintenance issues.

The drive is a scaled-up design from MPI’s trusted and patented M Series shaker conveyor line. The shaker system operates almost silently and uses a high efficiency motor to reduce operating costs. It is designed to transfer materials at a rate of up to 15 FPM.

The M-10000 series horizontal motion conveyor is different than traditional fiber leaf spring vibratory conveyors or electromagnetic vibratory conveyors that vibrate product at a high frequency. MPI’s horizontal motion conveyor uses a low frequency, smooth motion to move the product.

Specifications

US Customary Units

| Model # | GPM | Width of Roll | Length | Height | Width | Approx. Weight | |

| Water Based | Oil Based | IN | IN | IN | IN | LBS | |

| Eco-Flow 7 | 29 | 15 | 7 | 41.2 | 56.7 | 21.3 | 500 |

| Eco-Flow 11 | 46 | 23 | 11 | 41.2 | 56.7 | 25.3 | 550 |

| Eco-Flow 19 | 80 | 40 | 19 | 41.2 | 56.7 | 33.3 | 600 |

| Eco-Flow 38 | 160 | 80 | 38 | 41.2 | 56.7 | 52.3 | 650 |

Metric Units

| Model # | LPM | Width of Roll | Length | Height | Width | Approx. Weight | |

| Water Based | Oil Based | CM | CM | CM | CM | KG | |

| Eco-Flow 7 | 7.66 | 3.96 | 17.8 | 104.6 | 144 | 54.1 | 227 |

| Eco-Flow 11 | 12.15 | 6.07 | 27.9 | 104.6 | 144 | 64.3 | 250 |

| Eco-Flow 19 | 21.14 | 10.57 | 48.3 | 104.6 | 144 | 84.6 | 274 |

| Eco-Flow 38 | 42.27 | 21.13 | 96.5 | 104.6 | 144 | 132.8 | 295 |